8

2-3 Electrical Cautions

1.

After wiring, check the rotation of the spindle of the spindle. Turn the main

power switch “ON” and make sure the spindle is safe to turn. Then push jog

button (T) momentarily. The correct direction of the spindle rotation is counter

clockwise. (looking from tailstock end and have a downward movement of the

spindle operation control lever.) Wrong direction of the rotation can be corrected

by interchanging any two of the three phase lines (R.S.T.) in the power source.

2.

Checking each lubrication system’s oil level.

3.

Checking each handle if it is function normally.

4.

Checking belt tension adjustment to see if it is in good condition.

5.

Read and understand each section of the lathe before operation.

6.

When power indicator is “ON”, but spindle motor is not running. Overload

circuit breaker and electric magnetic contactor have act to protect motor from

overload, please reset the circuit breaker by press the reset toggle and lathe will

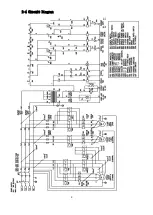

be able to operate again. (The electric wiring attached at chapter 2-4)

Summary of Contents for Dynamic 3370X

Page 5: ...5 1 Machine Assembly ...

Page 9: ...9 2 4 Circuit Diagram ...

Page 26: ...26 7 Leadscrew Add oil with oil gun As required Once per day 8 Bedways Auto lubrication ...

Page 27: ...27 5 4 Lubrication Location A Oil input hole B Oil drain hole ...

Page 33: ...33 7 1 Headstock Assembly ...

Page 39: ...39 7 2 Gear Box Assembly ...

Page 43: ...43 7 3 Gear Box Cover Assembly ...

Page 45: ...45 7 4 Apron Assembly Right Hand ...

Page 50: ...50 7 4 Apron Assembly Left Hand ...

Page 56: ...56 7 5 Machine Bed and Base Assembly ...

Page 60: ...60 7 6 Brake System ...

Page 63: ...63 7 7 Carriage and Crossfeed System ...

Page 67: ...67 7 8 Tailstock ...

Page 71: ...71 7 9 Chip Guard ...

Page 73: ...73 7 10 Leadscrew Cover and Rear Splash Guard ...