ABM International, Inc. Series: 1018/1022/1026/1032 V1.0

Model: Innova Longarm Quilting Machine Sequin

Proprietary information of ABM INTERNATIONAL, Inc. furnished for customer use only.

No other uses are authorized without the prior written permission of

ABM INTERNATIONAL, INC.

12

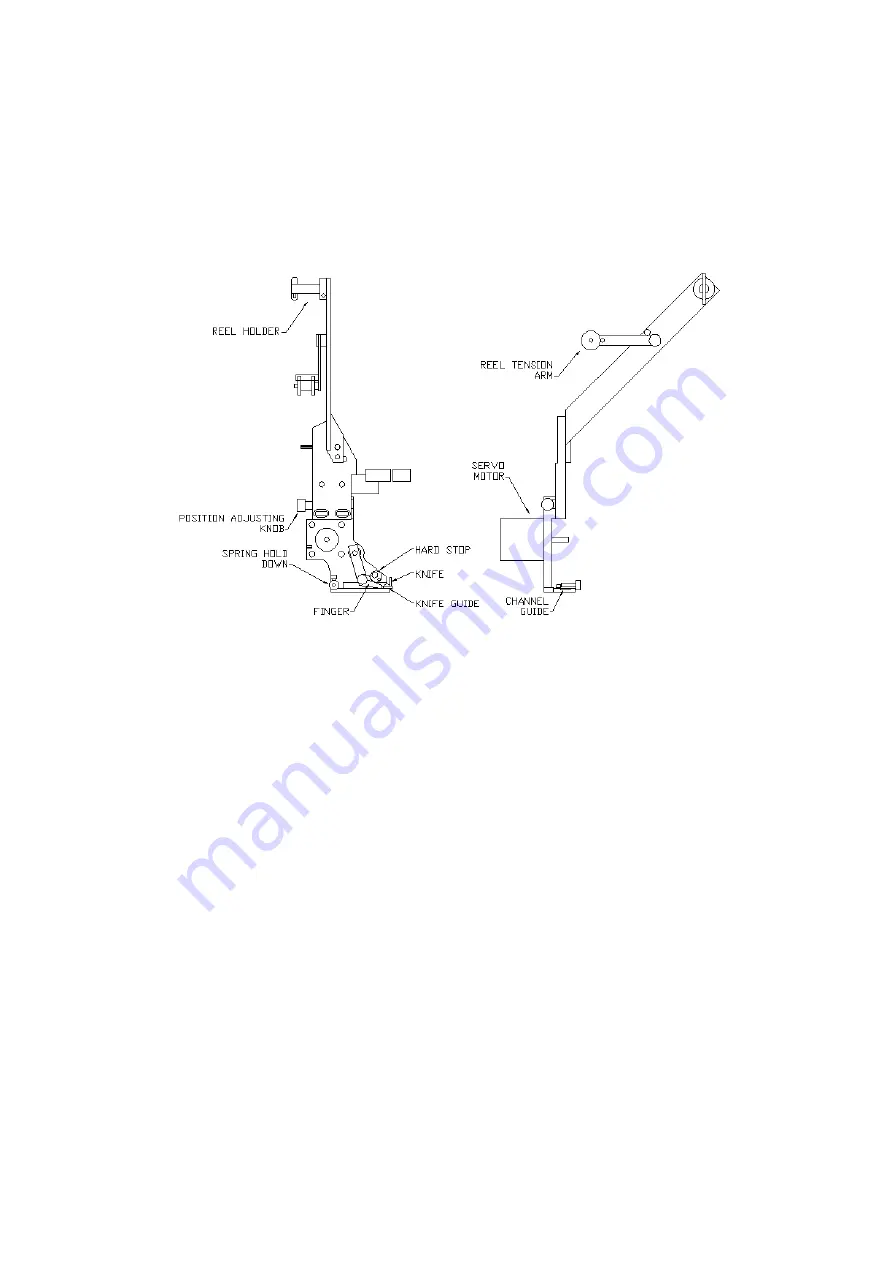

3.0 Anatomy of the Sequin Attachment

There are numerous components to the sequin attachment that must work together to produce a finished

product. Many of the parts have to be adjusted to feed and cut sequins properly. Brief descriptions of each item

are provided, followed by step-by-step instructions on how to adjust them.

Reel Holder –

Holds the reel of sequins to be sewn onto the finished product. The reel holder provides

a minimum tension on the reel to keep it from unwinding as the sequins are dispensed.

Reel Tension Arm -

Provides a constant tension to the string of sequins as they are dispensed.

Servo Motor -

Feeds the individual sequins based on speed of the machine and mode selected.

Position Adj. Knob -

Provides for small adjustments of the entire mechanism closer to or farther from the

needle for different size sequins.

Spring Hold Down -

Keeps the string of sequins from over-feeding or from back feeding as they are

dispensed.

Finger -

Engages the sequin in the center hole and feeds the sequin out to be cut.

Hard Stop -

Provides a mechanical stop for the finger as it feeds out sequins. It sets the position of

the fed sequin so the knife can cut it.

Knife -

Cuts the individual sequin from the string of sequins. The knife is actuated by the

needle bar end clamp.

Knife Guide -

Provides mechanical support for the knife and acts as a hold down for the front edge of

the channel guide.

Channel Guide -

The channel guide keeps the string of sequins flat, straight and in-line with the needle as

the sequins are dispensed.