19

English

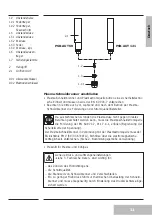

When using the plasma-cutting torch the user must be aware of the

relevant safety requirements:

• Startup and operation is reserved for persons with appropriate knowledge

in handling plasma cutting torches.

• Arc cutting may cause damage to eyes, skin and hearing. Therefore please

always wear the required safety clothing, eye and ear protection in compli-

ance with the relevant regulations in the country in question.

• The rating given represents maximum limit values.

Overloading can lead to torch damage or destruction.

• Before replacing consumables, switch off the power supply.

• Follow the operating instructions for the individual welding components,

e.g. for the power supply.

• Do not pull the cable assembly across sharp edges or set it down in the

cutting spatter area or on hot work pieces.

• Actuate torch button only when all precautions for cutting without hazards

are fulfilled.

• Use curtains or partitions to protect those not involved in the cutting process

from radiation and the danger of arc flashing.

• Work pieces, which have been degreased using chlorinated solvents, must

be thoroughly cleaned before welding starts, to avoid the risk of phosgene

forming.

For the same reason, no degreasing baths containing chlorine must be pla-

ced in the vicinity of the cutting area.

• Use the cutting torch only in a suitable environment. When used outdoors,

use suitable protection against all types of weather conditions.

• Observe fire hazard caused from spatter/dross created during cutting.

During cutting work remove everything combustible from the working area.

• During cutting work in confined spaces, electrical hazard is increased.

Protect yourself accordingly through use of insulating mats, dry clothing

and sufficient ventilation and exhaust

• All molten metals, especially lead, cadmium, copper, zinc and beryllium

are potentially harmful! Use ventilation or an extraction system to ensure

that specified MAC values are not exceeded.

• Place appropriate fire extinguishing equipment in the workplace, within

easy reach.

The components are carefully checked and packaged however damage may

occur during shipping.

Checking procedure on receipt of goods

– Check that the shipment is correct by referring to the shipping note.

In case of damage

– Check the package and components for damage (visual inspection).

6. Safety warnings

7. Shipment and

packaging

Summary of Contents for PSB Series

Page 27: ...27 Ruska...

Page 28: ......

Page 29: ...29 Ruska...

Page 30: ......

Page 31: ...31 esky...

Page 32: ......

Page 33: ...33 esky...

Page 34: ......

Page 35: ...35 Slovensky...

Page 36: ......

Page 37: ...37 Slovensky...

Page 38: ......

Page 39: ...39 Polski...

Page 40: ......

Page 41: ...41 Polski...