44

1

Medium voltage circuit

With a 2500 V megger, measure the insulation resistance

between the phases and the exposed conductive part of the

circuit.

Auxiliary circuits

With a 500 V megger (if the apparatus installed allows this),

measure the insulation resistance between the auxiliary cir-

cuits and the exposed conductive part.

Check that the connections to the control circuit are correct:

proceed at the relative power supply.

Carry out a few closing and opening operations (see cap. 6).

N.B.

Supply the undervoltage release and the locking magnet

on the operating mechanism at the relative rated voltage (if

provided).

Supply the spring charging geared motor at the relative rated

voltage.

Carry out a few closing and opening operations.

N.B.

Supply

the undervoltage release and the locking magnet on the oper-

ating mechanism at the relative rated voltage (if provided).

Supply the undervoltage release at the relative rated voltage

and carry out the circuit-breaker closing operation.

Cut off power to the release.

Close the circuit-breaker and

supply the shunt opening release at the relative rated voltage.

Open the circuit-breaker and supply the shunt closing release

at the relative rated voltage.

Open the circuit-breaker, keep the opening pushbutton

depressed, then turn the key and remove it from the housing.

Attempt the circuit-breaker closing operation.

Put the key back in and turn it 90°.

Carry out the closing operation.

With the circuit-breaker open, spring charged and locking

electromagnet not supplied, attempt circuit-breaker closing

both manually and electrically.

Insert the auxiliary contacts in suitable signalling circuits.

Carry out a few closing and opening operations.

With the circuit-breaker open, in the isolated for test position

and the locking electromagnet not supplied, attempt racking-in

of the circuit-breaker.

Supply the locking electromagnet and carry out the racking-in

operation.

Insert the auxiliary contacts in suitable signalling circuits.

With the circuit-breaker racked into the enclosure, carry out a

few traverse operations from the isolated for test position to

the connected position.

Take the circuit-breaker to the racked-out position.

The insulation resistance should be at least 50 Mohm and in

any case constant over time.

The insulation resistance should be a few Mohm and in any

case constant over time.

Operations and signals normal.

The operations and relative signals take place normally.

The spring is charged normally.

The signals are normal.

With the spring charged, the geared motor stops.

The geared motor recharges the spring after each closing

operation.

The circuit-breaker closes normally.

The signals are normal.

The circuit-breaker opens.

The signalling changes over.

The circuit-breaker opens normally.

The signals are normal.

The circuit-breaker closes normally.

The signals are normal.

Neither manual nor electrical closing takes place.

Both electrical and manual closing take place normally; in

this position the key cannot be removed.

Closing is not possible.

Signals take place normally.

Racking-in is not possible.

Racking-in takes place correctly.

The signals due to the relative operations take place normally.

Insulation resistance.

Auxiliary circuits.

Manual operating mechanism.

Motor operator (if provided).

Undervoltage release (if provided).

Shunt opening release and additional

shunt opening release (if provided).

Shunt closing release (if provided).

Key lock (if provided).

Locking electromagnet (-RL1)

(if provided).

Auxiliary contacts in the operating

mechanism.

Locking electromagnet on the truck

circuit-breaker (-RL2) (if provided).

Auxiliary transmitted contacts for

signalling circuit-breaker racked-in,

isolated (UniGear switchgear of

PowerCube modules).

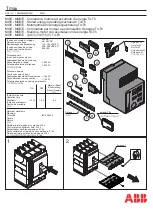

8. Putting into service

8.1.

General procedures

All the operations regarding putting into service must

be carried out by ABB personnel or by suitably qualified

customer personnel with in-depth knowledge of the

apparatus and of the installation.

Should the operations be prevented, do not force the

mechanical interlocks and check that the operating

sequence is correct.

The operating forces which can be applied for racking-in

withdrawable circuit-breakers are indicated in paragraph

7.5.

ITEM INSPECTED

PROCEDURE

POSITIVE CHECK

Before putting the circuit-breaker into service, carry out the following

operations:

– check tightness of the power connections to the circuit-breaker

terminals;

– establish the setting of the primary electronic overcurrent release

(if provided);

– check that the value of the power supply voltage of the auxiliary

circuits is between 85% and 110% of the rated voltage of the

electrical accessories;

– check that no foreign bodies, such as bits of packing, have got into

the moving parts;

– check that there is a sufficient exchange of air in the installation

place to avoid overtemperatures;

– also carry out the checks indicated in table T3.

T3

1

2

3

4

5

6

7

8

9

10

11

12