36

7. Maintenance

Maintenance operations are aimed at ensuring trouble-free

operation of the apparatus for the longest possible time.

The following operations must be carried out in accordance

with the IEC 61208/DIN 31051 Standards:

Inspection: Assessment of the actual conditions

Servicing: Measures to be taken to maintain the specified

conditions

Repairs:

Measures to be taken to restore the specified

conditions.

Notes

The following rules must be respected for all maintenance

operations:

– the relative specifications indicated in the “Standards and

specifications” chapter;

– the regulations for safety in the workplace indicated in the

“Putting into service and running” chapter;

– the regulations and specifications in the country of

installation.

7.1. General

It is good practice to keep a maintenance card and a service

book where all the operations carried out can be noted down

in detail, together with the date, description of the anomaly

and the references of data needed to identify the apparatus,

etc. (see chapter 2).

Experience gained in use of the apparatus will allow the

optimal time intervals for interventions to be established. In

any case, inspection of the apparatus not more than one year

after it has been put into service is recommended.

In case of need and for further details, please refer to what is

prescribed in article 10.4.2 of the Standard (IEC 62271-1).

In any case, for any problems, please do not hesitate to

contact us.

7.2. Handling the MAC-R2 electronic card

Management of sensitive devices outside protected areas is

considered to be “field work” and normally includes product

packing, unpacking, installation and maintenance.

In all these cases, handling the devices must be carried out

taking care to keep the potential of your hands and that of the

work surface earthed, with an equipotential connection to the

main grounding branch point.

It is advisable for the operator to wear conductive shoes and

overalls and to wear earthed conductive arm bands.

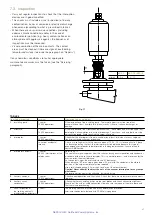

Fig. 13a-13b shows a maintenance kit consisting of an

arm band and ground connection, both fitted with a 1 MW

integrated resistance.

Using suitable protective means to protect the electronic

devices is an indispensable task requiring diligence and

attention. Inserting these procedures in the normal service

activities allows optimization of resources and underlines their

importance.

The main activities which allow an efficient protection system

to be maintained are:

• making personnel aware of the problems regarding

protection against electrostatic discharges, with reference

to the IEC 61340-5-1 Standards (these problems are often

unknown or underrated)

• training personnel in correct use of protection equipment

and on its perfect working order

• selecting protection materials suitable for the effective

production requirements and using them

• marking the protected area and highlighting the presence of

sensitive devices so as to attract the attention of operators

on correct use of the protection devices

• technicians must always set an example by respecting the

rules and using protection devices appropriately

Observe the following basic rules:

• avoid using tools which are unsuitable for removing the

electronic cards (e.g. screwdrivers, etc.)

• handling the electronic card during maintenance or

replacement operations must be limited to the minimum

time possible

• always hold the electronic card at the edges

• avoid touching the components mounted on the card

• pay attention when cables or connectors have to be

connected or disconnected

• avoid bending the card while inserting it in its seat or during

connector cabling

• avoid damaging the connectors, aligning the pins before

connecting the cable

Fig. 16

NEPSI.COM - Northeast Power Systems. Inc.