14

RS85

VIBR ATING FORK LEVEL SWITCH | OI/RS85-EN REV. K

Fault mode

If a fault is detected, either electrical or mechanical, LED 2 will

blink in RED and the normal ON relay is de–energized. This

LED is integral to the modular electronics and can only be

seen through the glass viewing cover.

Table 5 – Fault mode

Fault

Reason

Remedy

Does not

switch

No Power

Check power

Faulty wiring

Check wiring

Faulty electronic Module

Replace module

Density of liquid too low

Confirm that density is above

.5 SG

Fork encrusted with too

much buildup

Clean fork

Fork corroded or bent

Exchange fork and

process connection (requires

sending to factory)

Contacts welded together

(after short–circuit)

Replace module; put fuse in

contact circuit

Switches

incorrectly

Fail–safe mode

set wrong

Set correct mode at electronic

module

Sporadic

faulty

switching

Relay switches on & off

while in dry fork conditions

Recalibrate switch in process

connection

Thick heavy foam, very

turbulent conditions,

foaming liquid

Set time delay

Extreme RFI

Use shielded cable

Water in housing

Remove water, screw cover and

cable gland tight

Output overloaded

Reduce load: (cable) capacitance

5 Troubleshooting

.

.

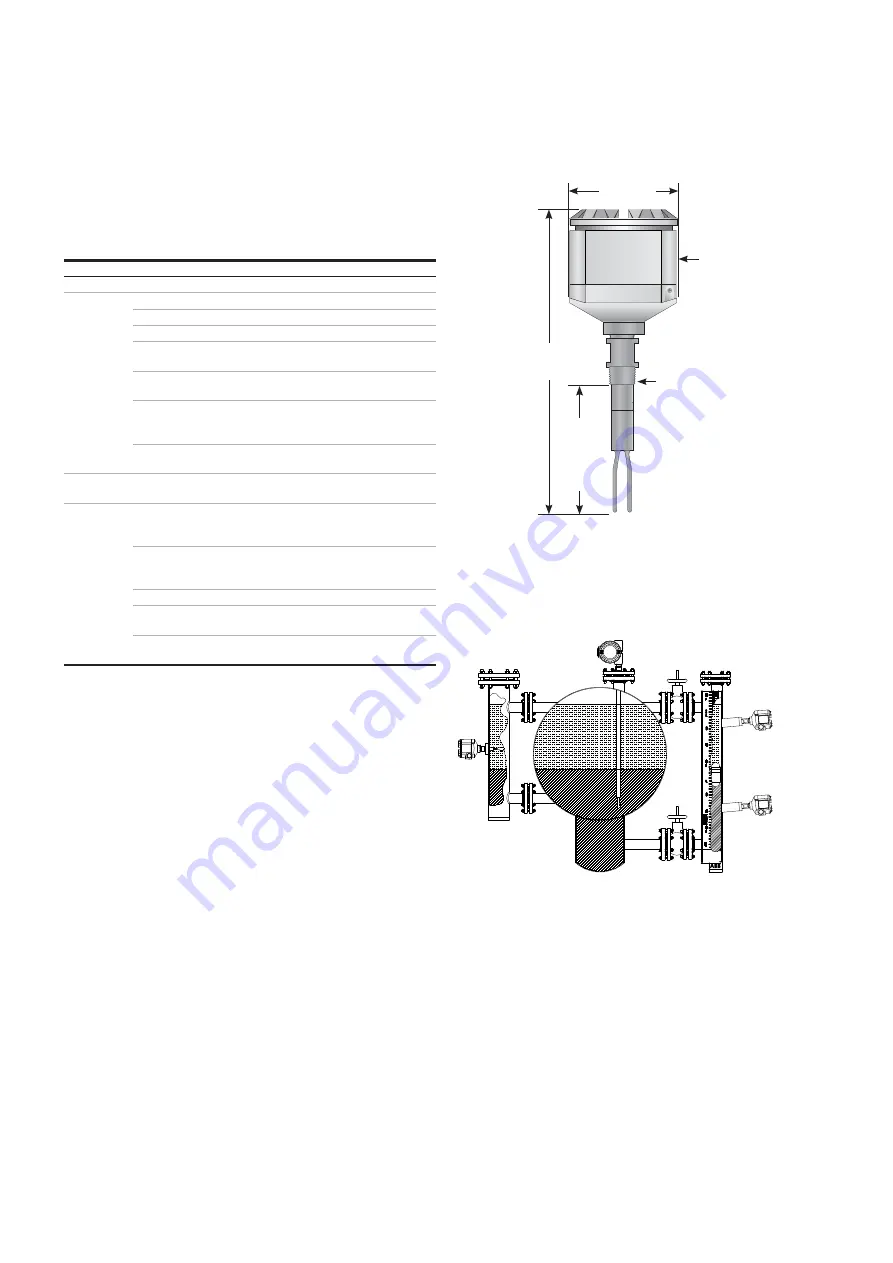

2

.

.

.

.

RS85

switches

mounted

in external

chamber

RS85 dual

compartment

housing and custom

insertion length

RS85

switches

mounted in

KM26 magnetic

level gauge

Standard

86 mm

(3⅜ in)

PL*

279 mm (11 in)

standard

111 mm

(4⅜ in)

19 mm (¾ in)

MNPT

standard

19.05 mm (¾ in)

FNPT conduit

Standard single compartment dimensions

Resonator sample applications

Figure 28

Figure 29