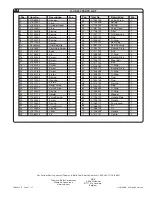

TROUBLESHOOTING

3.3

Problem

Cause

Solution

The ram will not advance.

Air in hydraulic system.

Insufficient hydraulic oil.

Hold the tool with head towards the floor to

allow air to rise towards top of oil bladder.

Defective hydraulic circuit.

Consult tool service.

The ram will not retract

Tool did not complete a full cycle and

bypass.

Operate pump handle and allow tool to reach

full pressure and bypass, or depress release

to retract the ram.

The connector is jammed in compression

dies.

Depress and hold release button while prying

compression dies apart.

Remove body handle and check on

reservoir for proper or level. The oil should

be at the top of the reservoir when the cap

is removed. Ram should be fully retracted

before removing cap.

The release button is bent or misaligned.

Consult tool service.

TA04922 B Page 5 of 7

4.0

IMPORTANT OPERATING PRECAUTIONS

4.1

PRECAUTIONS FOR COMPRESSION TOOL

1. Select the appropriate dies for the connector and conductor to be compressed. Incorrect combinations result in inferior

connections between the connector and conductor and are an electrical hazard.

2. Never operate the tool without dies installed.

3. Always point the tool away from other people.

4. If the tool is stored for an extended period at a temperature of less than 25º F (-5º C), the tool should be allowed to return to

room temperature to ensure smooth operation. Use the tool only after it has been at room temperature for 1 hour.

5. Do not drop the tool. Dropping the tool may damage the hydraulic circuit and cause malfunctions.

6. Keep the head and ram clean and free of debris. Solvents can be used to clean the head but should not be used on the

plastic body. Use soap & water to clean the body.