22

PME120-AI / PME120-AN (Contrac)

ELECTRICAL ROTARY ACTUATOR | SEI/PME120-EN REV. A

… 6 Electrical connections

… Fuses

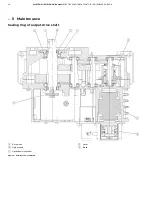

Fuse location

Integrated electronic unit (PME120-AI)

1

Main pcb

2

Mains fuse

3

Spare fuse for mains supply

4

Fuse for analog setpoint input

5

Heater fuse

(only for −25

°C version)

Figure 27: Fuse location PME120-AI

EAN823

NOTICE

Remove the cover of the connection chamber carefully in

order to avoid any damage

1

Tap holes for cable glands

2

Cable gland

3

Analog input fuse

4

Terminals (signals)

5

Anti-dewing heater fuse

6

Terminals (motor cable)

7

Power supply fuse

8

Terminals (power supply)

Figure 28: Fuse location EAN823

EAS822

1

Digital output fuses

2

Mains fuse

Figure 29: Fuse location EAS822

Details: Digital output fuses

1

Fuse for DO3

2

Fuse for DO2

3

Fuse for DO1

Figure 30: Detail view of output fuses