25

The peak current during charging is calculated by the equation in

Checking the

charging capacity

.

Charging time is longer if a higher resistance value is used.

It must be checked that AC supply side components can withstand the peak current.

Charging resistor energy withstand is calculated by equation E = 1.3CU

2

where C is

total capacitance of DC-link capacitors and U is supply line-to-line rms voltage for

example 400 V or 500 V. The factor 1.3 covers the upper tolerance limit of

capacitance.

If drive units with different charging circuits are used, the DC-links must be connected

together via contactors.

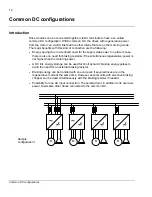

Frame sizes A…D

If only frames A…D are used, there is no need for an external charging circuit with the

external DC supply, because the drive modules have internal charging circuits in series

with DC-link capacitors.

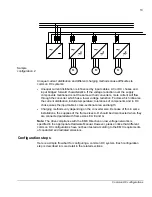

Frame sizes E0, E and G

In frame sizes E0, E and G, the charging circuit is in parallel with the input bridge.

Separate charging circuit is needed.

The AC fan of ACS850 frame G must be powered separately. See chapter

Powering

the AC fan in frame G

.

Supply units other than ACS850

When some other type of supply unit than ACS850 is used, its DC voltage compatibility

with the drive units must be checked in addition to the earlier described items (see

section

DC voltage limits

).

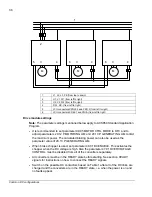

Mains choke selection

In common DC connections, the drive module(s) connected to the AC supply must be

equipped with mains choke(s). The mains chokes are needed:

•

to get the maximum DC power ratings from the drive module(s)

•

to reduce the AC input current (rms, peak) level

•

to meet the requirements for harmonic distortion

•

to balance the supply current in a multiple AC input.

Common DC configurations

Summary of Contents for ACS850 series

Page 1: ...ACS850 Common DC configuration application guide...

Page 2: ......

Page 4: ......

Page 6: ...6 Safety instructions...

Page 9: ...9 Table of contents...

Page 11: ...11 Introduction to the manual...