7

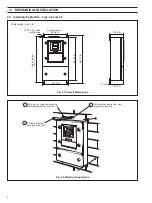

De-bubbler

Part Number

7997 500

91

150 CRS

Removable Fitting

To Fit 12 mm i.d. Tube

88

Ø6.5

Sample Outlet

Quick-release

Fittings

to Suit 12 mm

I.D. Tube

(rotatable

through 360

°

)

540

Sample Inlet

Drain Outlet

Important Note.

The de-bubbler

MUST

be mounted vertically

with the flow upwards.

Dimensions in mm

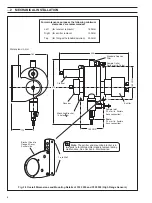

Tundish

Valve (A)

= Optional

Minimise height

to avoid syphoning

effect

Important Note.

For the high range sensor a higher

minimum flowrate is required at high turbidity levels.

1

2

Valve (B)

Flow Regulator Valve

Adjust the sample flow through the system

(0.5 to 5 l/min) using the regulating valve (B).

Open the ‘sample in’ isolating valve (A)

such that the overflow from the de-

bubbler is at a minimum.

Note.

Sample regulating

valves together with a flow indicator

are recommended to ensure easy

maintenance and consistent

performance. These devices are

not supplied with the 7320 Series

UV Organic Pollution Monitoring

system.

Important Note.

The de-bubbler

MUST

be

mounted vertically with the flow

upwards.

Tundish

Minimise height

to avoid syphoning

effect

Sample

Outlet

Connector

Sample in

Flow Regulator

Valve

De-bubbler

Drain

Outlet

7320 100

7320 000

2

MECHANICAL INSTALLATION

Fig. 2.6 Overall Dimensions and Mounting Details of the De-bubbler

Fig. 2.7 Typical System Installation

2.4

Mounting the De-bubbler – Fig. 2.6

2.4.1

Set Up Procedure for Optional De-bubbler – Fig. 2.7