26

B - The Stratford Si

Take out the removable items from the appliance (see section 18 Handling). Plug boiler connections, which are

not required.

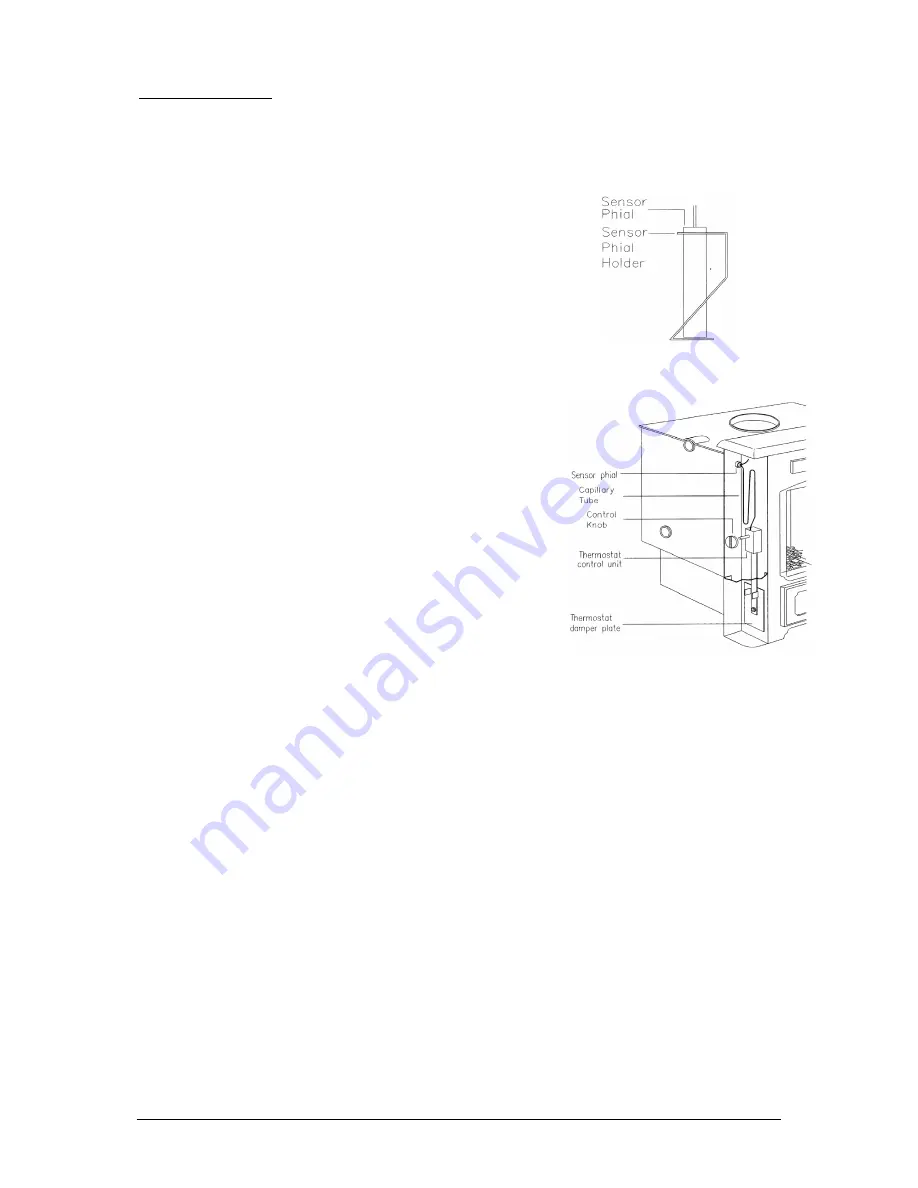

Checking the thermostat.

The thermostat is fitted within the outer casing on the left hand side of

the unit's front. To remove the side panel loosen the top and bottom

screws which can be found through the 2

nd

from top and bottom vents,

the side panel can then be lifted up and off its key hole slots. The

control knob which is inside the fire for despatch is fitted on to the

shaft through the hole in the left hand casing. It is, however, advisable

to check the cold setting of the thermostat before installing and

running the appliance. This is best seen from inside the appliance with

the grate, fuel retainer bars, ash pan, etc., removed.

With the control set at minimum the damper should be just touching

the side of the ash pit chamber all round the air inlet grill.

With the control set at maximum (8) and the damper plate floating in

its natural position, there should be a gap of approximately 27mm

between the body and the edge of the damper plate furthest from the

control shaft.

If the cold setting does require adjustment it will be necessary to

remove the front trim to give access to the thermostat. To do this first

remove the control knob from the thermostat shaft, then slacken the

screws, which fix the casing to the unit front (a screwdriver can be

inserted through the slots on the radius corner of the casing): the back

of the casing laps over the flange of the unit front. Lift the casing and

pull forward to remove. Adjust the setting by slackening off the lock-

nut.

Replace the casing on the unit front and refit the control knob on to

the thermostat shaft.

Positioning Appliance in recess.

Apply a thin cement slurry to the back of the hearth so that when the appliance is introduced into the opening the

rim of the base forms a seal with the hearth.

Note:

When installing a convector unit is it particularly important that any backfilling does not force material

into the airway beneath the base plate thereby obstructing the circulation of air through the unit.

Insert the appliance into the recess, keeping it central, until the back of the front section buts against the flat

surface of the fireplace surround. A satisfactory seal must be made and it may be necessary to interpose a sealing

rope and fire cement between the appliance and the face of the fireplace surround.

Boiler unit only.

Connect pipe work to the boiler unit. The connected pipes should be screwed to a maximum depth of 15mm

from the face of the tapping, (female 1" B.S.R). Steel integral boilers should be connected to an indirect hot

water tank system.

Note: the flow and return sections of any circuit must always be opposite of appliance. Remember to

incorporate a draining plug/tap at the lowest point to facilitate drainage & flushing.

Fill and test the system, adding Fernox or similar corrosion inhibitor to prevent corrosion and the formation of

lime scale.

It is also essential that the return water temperature remains in excess of 45 degrees centigrade

(Celsius). The gravity return should be fitted with a thermostat, which will activate a cut-out on the

radiator circulating pump, should the temperature drop below this level.

Warning: if a pipe stat is not fitted then cold water corrosion can occur.

FAILURE TO COMPLY WITH THESE REQUIREMENTS WILL INVALIDATE THE GUARANTEE

Summary of Contents for Stratford Sf 30

Page 34: ...34 Manufactured by July 2001...