17

PLANNING THE VENT SYSTEM

Plan the route of the vent system from the discharge of the blower

to the planned location of the vent terminal.

1. Layout total vent system to use a minimum of vent pipe and elbows.

2. This water heater is capable of venting flue gases equivalent to

25' (7.6 m) of 2" pipe, 65' (19.8 m) of 3" pipe, or 128' (39.0 m) of

4" pipe as listed in Table 1.

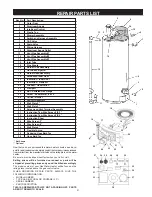

TABLE 1

Number of

2" Maximum

3" Maximum

4" Maximum

90° Elbows

Pipe - ft. (m)

Pipe - ft. (m)

Pipe - ft. (m)

1

20 (6.1)

60 (18.3)

120 (36.6)

2

15 (4.6)

55 (16.8)

112 (34.1)

3

10 (3.0)

50 (15.2)

104 (31.7)

4

--

45 (13.7)

96 (29.3)

5

--

40 (12.2)

88 (26.8)

6

--

35 (10.7)

80 (24.3)

The minimum vent lengths for each of the pipe sizes is one 90° on

top of the unit plus 2' (61 cm) of straight pipe and the appropriate

termination.

NOTE:

The equivalent feet (m) of pipe listed above are exclusive

of the termination. That is, the termination, with an installed

screen, is assumed to be in the system and the remainder of the

system must not exceed the lengths discussed above.

3. The blower discharge adapter is made to accept only straight

sections of 2" pipe. To start, a minimum of 2 inches (5.1 cm) of

2" pipe must be attached to the blower discharge, see Figure 17.

If using 2" inch vent pipe:

A minimum of 2 inches (5.1 cm) must be attached to the blower

before the first elbow. After the first elbow add the additional

venting required for the installation. The total system cannot

exceed the lengths discussed above, where each elbow is

equal to 5 feet (1.5 m) of straight pipe.

If using 3" or 4" inch vent pipe:

Two inches (5.1 cm) of pipe must be attached to the blower discharge

before adding a reducer to acquire the desired pipe diameter. An

appropriately sized 45 degree elbow (supplied locally-a schedule 40

DWV) vent terminal must be obtained with an equivalent screen

(supplied in vent kit). The total system cannot exceed the equivalent

pipe lengths discussed above where each elbow is equal to 5 feet

(1.5 m) of straight pipe (3" vent pipe) or 8 feet (2.4 m) of straight pipe

(4" vent pipe).

NOTE:

This unit can be vented with PVC pipe materials (Cellular

Core ASTM-F891; DWV ASTM-D2665 or CSA B181.2; Schedule

40, 80, 120 ASTM-D1785 or CSA B137.3; or SDR Series ASTM-

D2241 or CSA B137.3), CPVC pipe materials (CPVC41 ASTM-

D2846 or CSA B137.6; Schedule 40, 80 ASTM-F441 or CSA

B137.6; or SDR Series ASTM-F442), ABS pipe materials

(Schedule 40 DWV ASTM-D2661 or CSA B181.1 or Schedule

40 DWV Cellular Core ASTM-F628). The fittings, other than the

TERMINATION should be equivalent to PVC-DWV fittings

meeting ASTM D-2665 (Use CPVC fittings, ASTM F-438 for CPVC

pipe and ABS fittings, ASTM D-2661/3311 for ABS pipe). If CPVC

or ABS pipe and fittings are used, then the proper cement must

be used for all joints, including joining the pipe to the Termination

(PVC Material). If local codes do not allow the use of the PVC

termination when a material other than PVC is used for venting,

then an equivalent fitting of that material may be substituted if

the screen in the PVC terminal is removed and inserted into the

new fitting.

PVC Materials should use ASTM D-2564 Grade Cement; CPVC

Materials should use ASTM F-493 Grade Cement and ABS

Materials should use ASTM D-2235 Grade Cement.

If the water heater is being installed as a replacement for an existing

power vented heater in pre-existing venting, a thorough inspection

of the existing venting system must be performed prior to any

installation work. Verify that the correct material as detailed above

has been used, and that the minimum or maximum vent lengths

and terminal location as detailed in this manual have been met.

Carefully inspect the entire venting system for any signs of cracks

or fractures, particularly at the joints between elbows and other

fittings and the straight runs of vent pipe. Check the system for

signs of sagging or other stresses in the joints as a result of

misalignment of any components in the system. If any of these

conditions are found, they must be corrected in accordance with

the venting instructions in this manual before completing the

installation and putting the water heater into service.

NOTE:

A.

For water heaters in locations with high ambient

temperatures (above 100°F) it is recommended that CPVC or

ABS pipe and fittings be used.

B.

A 22.5 degree elbow (2" vent

pipe) or a 45 degree elbow (3" and 4" vent pipe) with an installed

screen VENT TERMINAL must be used in all cases.

4. There will be some installations where condensate will be formed

in the horizontal runs of the vent system. This condensate will

run into the condensate boot attached to the blower and out the

fitting. The water heater is shipped with condensate hose that

attaches to the fitting on the condensate boot. No other Tee or

fitting is required. See Figures 17, 20 and 21.

CONDENSATE

This water heater is a condensing unit and requires a drain to be

located in close proximity to allow the condensate to drain safely. The

condensate drains from the unit at the exhaust tee located at the

bottom of the unit (see figure 16) and from two places on the blower

assembly (see figure 17). Condensate from this water heater is mildly

acidic. Please note that some local codes require that condensate is

treated by using a pH neutralizing filter prior to disposal.

NOTE: It is important that the condensate hose on the bottom of the

unit is not installed elevated above the clamp that is secured to the side

of the jacket, see figure 16. This must be true for the entire length of the

hose from the clamp to the exit into an appropriate drain. If these

instructions are not followed or if the condensate hose is blocked, water

will spill from the condensate trap. As with every water heater installation,

a drain pan should be used to prevent water damage to the surrounding

area. If necessary, a condensate pump with an incorporated reservoir

may be used to pump the water to an appropriate drain. To avoid

condensate spillage, select a pump with an overflow switch.

Caution must be used to ensure that the drain is free and clear of

debris and will not allow backflow through the condensate hose.

Consideration must be given to avoid freezing of the condensate lines

which could result in excessive build up of condensate inside the water

heater. Waterproof heat tape may be required to prevent freezing of the

condensate lines. Please ensure that the outlet of the condensate drain

does not create a slippery condition which could lead to personal injury.