5

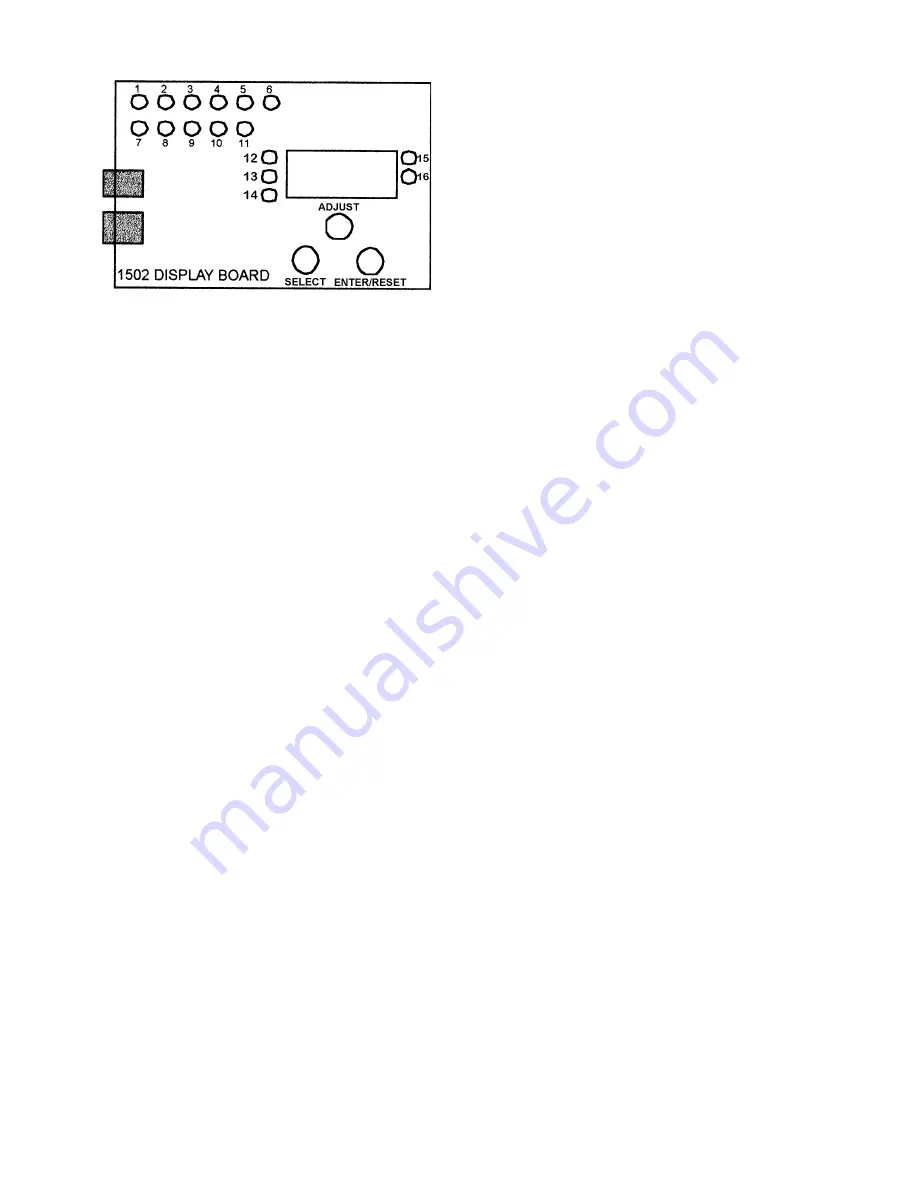

Figure 1. Dia-Scan II Display Board.

Green Status Lights

LED 1: Call for Heat

LED 2: Flow Switch

LED 3: Pressure Switch

LED 4: Ignitor Current

LED 5: Gas Valve

LED 6: Flame Sense

Red Fault Lights

LED 7: Ignition Fail

LED 8: Circulate Failure

LED 9: Blower Failure

LED 10: Blocked Inlet

LED 11: Blocked Flue

Water Temperature Set Lights

LED 12: Inlet Water Temperature *

LED 13: Outlet Water Temperature

LED 14: Inlet/Outlet Differential Temperature

LED 15: Set-Point Temperature

LED 16: Outlet/Set-Point Differential Temperature

* Defaults to tank probe temperature when tank probe is used.

Temperature Set-point Adjustment Procedure

The control board has a standard programmable temperature set-

point range of 110°F to 240°F. The user can easily change the

temperature set-point at any time by using the following procedure.

In all cases, the boiler must be energized. The factory default set-

ting is 180°F.

To change or view the current programmed temperature set-point

value:

1.

Press the SELECT push-button on the display board until both

the Set-Pt LED (LED 15, see figure 1) and Outlet Water Tem-

perature LED (LED 13, see figure 1) are illuminated.

2.

The LED display will show the current set-point temperature.

3.

Press and hold the ADJUST push-button. The displayed tem-

perature will either increase or decrease. To alternate between

increasing or decreasing the temperature, release then press

and hold the ADJUST push-button.

4.

When the desired set-point temperature is reached, release

the ADJUST push-button.

5.

Press the ENTER/RESET push-button once, this enters the

selected set-point temperature into controller memory.

6.

The appliance will now control the temperature to the desired

set-point value.

NOTE: The boiler must complete a full cycle in order for the

new setting to take effect. If the unit is turned off

prior to a complete cycle the setting will be lost and

the previous setting will remain in effect.

If the ADJUST push-button is held down long enough, the set-point

will reach 110°F, the minimum value (or 240°F, the maximum value)

and stop. At this point, if the desired set-point is not obtained, re-

lease the ADJUST push-button and depress it again. The set-point

value will now restart at 110°F (240°F) and once again increase

(decrease) in value for as long as the ADJUST push-button is

pressed.

Switching Differential Adjustment Procedure

To facilitate proper operation and maximize appliance performance,

the control has a programmable operating switching differential or

"hysteresis" about the set point. This means a call for heat will

become active when the water temperature measured at the outlet

temperature sensing probe (Probe #1) drops to the set-point value

minus the switching differential value. The burner will remain on

until the water temperature measured at probe #1 reaches the set-

point value. The switching differential value is fully programmable

from 5°F to 50°F using the push-button(s) located on the Display

Board. The default is set at 20°F.

To change or view the current programmed switching differential:

1.

Press the SELECT push-button on the display board until

the Set-Pt differential LED (LED 16, see figure 1) is illumi-

nated.

2.

The LED display will show the current switching differential.

3.

Press and hold the ADJUST push-button. The displayed value

will either increase or decrease. To alternate between increas-

ing or decreasing the switching differential, release then press

and hold the ADJUST push-button.

4.

When the desired switching differential is reached, release

the ADJUST push-button.

5.

Press the ENTER/RESET push-button once, this enters the

selected switching differential value into controller memory.

6.

The appliance will now control temperature utilizing the de-

sired switching differential value.

If the ADJUST push-button is held down long enough, the switching

differential setting will reach 5, the minimum value (or 50, the maxi-

mum value) and stop. At this point, if the desired switching differen-

tial is not obtained, release the ADJUST push-button and depress it

again. The switching differential value will now restart at 5 (50) and

once again increase (decrease) in value for as long as the ADJUST

push-button is pressed.

Circulating Pump Adjustment Procedure

The Controller is factory set with a 45 second post

circulate func-

tion. Using the Display Board, the user has the capability to choose

between a 45, 90, or 180 second post circulate time period, or turn

the pump on continuously. This provides flexibility in selecting the

post circulate time to meet specific application requirements, and

improves the efficiency of the circulating pump operation.