16

forming droplets, these drip into the fire or run out on the floor.

This is common at the time of startup after installation, during

periods of time when incoming water is very cold, or the heater

may be undersized for the requirements.

Droplets from the bottom of the flue may be due to corrosive

combustion products or improper vent. Check with your dealer

for more information.

CATHODIC PROTECTION - ANODE (FIG. 1)

The anode rod within the tank is designed to be slowly consumed

cathodically, minimizing corrosion in the glass lined tank. A

hydrogen sulfide (rotten egg) odor may result if water contains

high sulfate and/or minerals. Chlorinating the water supply should

minimize the problem. (See EXTENDED NON-USE PERIODS).

NOTE: Anode must remain installed (except for inspection) to

avoid shortening tank life. See LIMITED WARRANTY. Replace

as necessary.

WARNING

: DO NOT BY-PASS ANY CONTROLS TO MAKE HEATER OPERATE.

OPERATE ONLY AS WIRED FROM FACTORY.

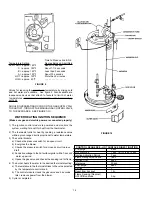

TROUBLE SHOOTING

Please check guidelines below. For your safety, water heater service should be performed only by a qualified service technician.

Read the GENERAL SAFETY INFORMATION section first.

PROBLEM

LED STATUS

CAUSE

SOLUTION

Check for power to heater.

Off

No power to system control.

Check wiring harness for proper connections.

Check for line voltage at harness connectors.

Slow Blink

Bright-Dim

Normal operation

Not applicable.

1 Flash

Setpoint error, internal failure detected.

Replace gas control valve.

Replace pressure switch.

Replace pressure switch.

2 Flashes

Pressure switch failed to open.

Replace blower assembly.

Replace pressure switch.

3 Flashes

Pressure switch failed to close.

Replace blower assembly.

ECO activated.

Replace ECO.

4 Flashes

Blower Assembly is energized.

Replace gas control valve.

Internal hardware failure.

Replace gas control valve.

Insure that burner stays lit.

GAS

Flame signal sensed out of sequence.

Insure that igniter wires are not loose at gas valve.

VALVE

Replace gas control valve.

Insure that burner stays lit.

Blower Assembly is energized.

Insure that igniter wires are not loose at gas valve.

Replace gas control valve.

Gas supply is off or too low to operate.

Damaged or broken HSI element.

Appliance not properly earth ground.

Flame sense rod contaminated or not positioned

correctly.

6 Flashes

System lockout.

HSI element not positioned correctly.

HSI element or flame sense rod wiring not

connected properly.

Less than 100Vac between flame rod and burner

pan with 120Vac input to control.

Cycle external power or remove request for heat

for 2 seconds before reapplying.

Water temperature is below 36°F.

Wait until gas control generates a self-reset.

Rapidly

Loose connection between valve

Make sure connections

blinking

and spud assembly.

are properly seated.

Internal component failure.

Replace gas control valve.