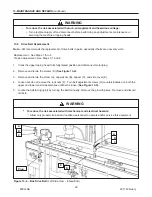

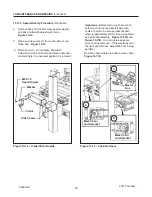

13.10 Drive Belt Tension

Tension adjustment of the drive belts may be required during normal operation. Belt tension must be adequate to

positively move the box through the machine and they should run fully on the surface of the pulleys at each end of

the frame. The idler pulleys on the infeed end are adjusted in or out to provide proper belt tension. Each belt is

adjusted separately.

Belt tension is obtained by tightening the adjustment screw so that a moderate pulling force of 3.5 kg [7 lbs]

applied at the mid span, as shown in

Figure 13-7,

will de

fl

ect the belt 25mm [1 inch]. This will assure positive

contact between the belt and the drive pulley on the discharge end of the taping head.

To adjust belts, see "Maintenance – Drive Belts", steps 3 and 7.

•

To reduce the risk associated with pinch, entanglement and hazardous voltage:

−

Turn electrical supply off and disconnect before performing any adjustments, maintenance or

servicing the machine or taping heads

WARNING

13-MAINTENANCE AND REPAIRS

(continued)

31

Figure 13-7 – Box Drive Belt Tension Adjustment, Top View

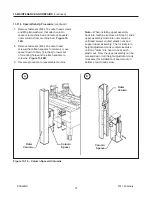

13.11 Special Set-Up Procedure

The following changes to the case sealer will allow taping boxes 90mm [3-1/2 inches] minimum height.

•

To reduce the risk associated with mechanical and electrical hazards:

−

Turn electrical and air supply off and disconnect before performing any adjustments,

maintenance, or servicing the machine or taping heads

WARNING

1. Raise the upper head assembly (by turning crank handle counterclockwise). Remove and retain the two

screws and washers from the normal position holes "A-A".

2. Remount and secure the stop bracket in the lower position "A" using the top holes and original fasteners.

5H

locate both the right and left stop brackets.

13.11.1 Case Sealer Frame

(Refer to

Figure 13-8A

)

Infeed End

Discharge End

Box Drive Belt

Drive Belt

Direction

25mm [2 Inch] Defl ection

@ 3.5 kg [7 lbs.] Pull Force at Midspan

2011 February

800at-NA

Summary of Contents for 39600

Page 4: ...THIS PAGE IS BLANK ...

Page 6: ...THIS PAGE IS BLANK ...

Page 8: ...8 THIS PAGE IS BLANK ...

Page 10: ...THIS PAGE IS BLANK ...

Page 48: ...36 THIS PAGE IS BLANK ...

Page 50: ...38 THIS PAGE IS BLANK ...

Page 52: ...40 THIS PAGE IS BLANK ...

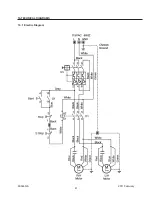

Page 53: ...41 16 TECHNICAL DIAGRAMS 16 1 Electric Diagram 2011 February 800at NA ...

Page 56: ...44 THIS PAGE IS BLANK ...

Page 58: ...46 2011 February 800at NA 800at Figure 10440 ...

Page 60: ...48 2011 February 800at NA 800at Figure 3269 ...

Page 62: ...50 2011 February 800at NA 800at Figure 5350 1 ...

Page 64: ...52 2011 February 800at NA 800at Figure 5817 ...

Page 66: ...54 2011 February 800at NA 800at Figure 6162 1 ...

Page 68: ...56 2011 February 800at NA 800at Figure 6162 2 OPTIONAL ...

Page 70: ...58 2011 February 800at NA 800at Figure 6163 1 ...

Page 72: ...60 800at 2011 February 800at NA Figure 6163 2 Rear ...

Page 78: ...66 Figure 6165 800at 2011 February 800at NA ...

Page 80: ...Figure 6166 800at 2011 February 800at NA ...

Page 82: ...70 THIS PAGE IS BLANK ...

Page 84: ......

Page 86: ...THIS PAGE IS BLANK ...

Page 88: ...THIS PAGE IS BLANK ...

Page 92: ...2 THIS PAGE IS BLANK ...

Page 116: ...26 2 STD Taping Head 2010 May 26 Figure 10387 Upper Head 9 9 1 9 4 5 3 8 7 9 9 2 9 10 11 ...

Page 118: ...28 2 STD Taping Head 2010 May 28 Figure 10395 Upper and Lower Heads 4 2 1 6 3 3 5 6 4 5 ...

Page 126: ...2 STD Taping Head 2010 May 36 Figure 10389 Lower Head 9 11 7 2 3 8 5 4 1 9 9 10 9 9 9 ...

Page 128: ...38 THIS PAGE IS BLANK ...

Page 129: ...39 ...

Page 130: ...40 ...