7

3M™ Inline Sander accessories are designed for use on 3M Inline Sanders.

Constructed from premium, industrial-quality materials, their durability and

precise construction are the ideal complement to the performance of the 3M

Inline Sander. See Product Configuration/Specifications table for mounting

information for a particular model.

1. Read all instructions before using this tool. All operators must be fully

trained in its use and aware of these safety rules.

2. The tool RPM should be checked on a regular basis to ensure proper

operating speed. This check should be done by inserting a touch-type

tachometer into the spindle of the tool without an abrasive product mounted.

3. Make sure the tool is disconnected from the air supply. Select suitable

abrasive, mounting hardware and accessories and secure them to the

spindle. Be careful to center the abrasive & mounting hardware.

4. Always wear required safety equipment when using this tool.

5. Always remove the air supply to the sander before fitting, adjusting or

removing the abrasive & mounting hardware.

6. Always adopt a firm footing and grip and be aware of torque reaction

developed by the sander.

7. Use only 3M approved spare parts.

8. Always ensure the material being worked is firmly fixed to avoid movement.

9. Check hose and fittings regularly for wear. Do not carry the tool by its hose;

always be careful to prevent the tool from being started when carrying the

tool with the air supply connected.

10. Dust is highly combustible.

11. If tool is serviced or rebuilt check to ensure that the maximum tool RPM is

not exceeded and that there is no excessive tool vibration.

12. Do not exceed maximum recommended air pressure. Use safety equipment

as recommended.

13. Prior to installing any abrasive, wheel or mounting hardware, always check

that their marked maximum operating speed is equal or higher than the

rated speed of this tool.

14. The tool is not electrically insulated. Do not use where there is a possibility

of contact with live electricity, gas pipes, and/or water pipes.

15. This tool is not protected against hazards inherent in grinding and cutting

operations, which require a guard, and no such grinding and cutting

products should ever be attached.

16. Take care to avoid entanglement with the moving parts of the tool with

clothing, ties, hair, cleaning rags or loose hanging objects. If entangled, stop

air supply immediately to avoid contact with moving tool parts.

17. Keep hands clear of the spinning abrasive & mounting hardware or spindle

during use.

18. If the tool appears to malfunction, remove from use immediately and

arrange for service and repair.

19. Immediately release the start handle in the event of any disruption of

pressure; do not attempt to restart until the disruption has been corrected.

20. Do not allow the tool to free spin without taking precautions to protect

any persons or objects from debris from rupturing abrasive & mounting

hardware.

21. When tool is not in use, store in a clean dry environment free of debris.

22. Recycle or dispose of tool according to Local, State, and Federal regulations.

23. Whipping hoses can cause severe injury.

24. Whenever universal twist couplings (claw couplings) are used, lock pins

shall be installed and whip check safety cables shall be used to safe

guard against the possible hose-to-tool connection failure.

Safety Precautions

3M™ Inline Sander Accessories

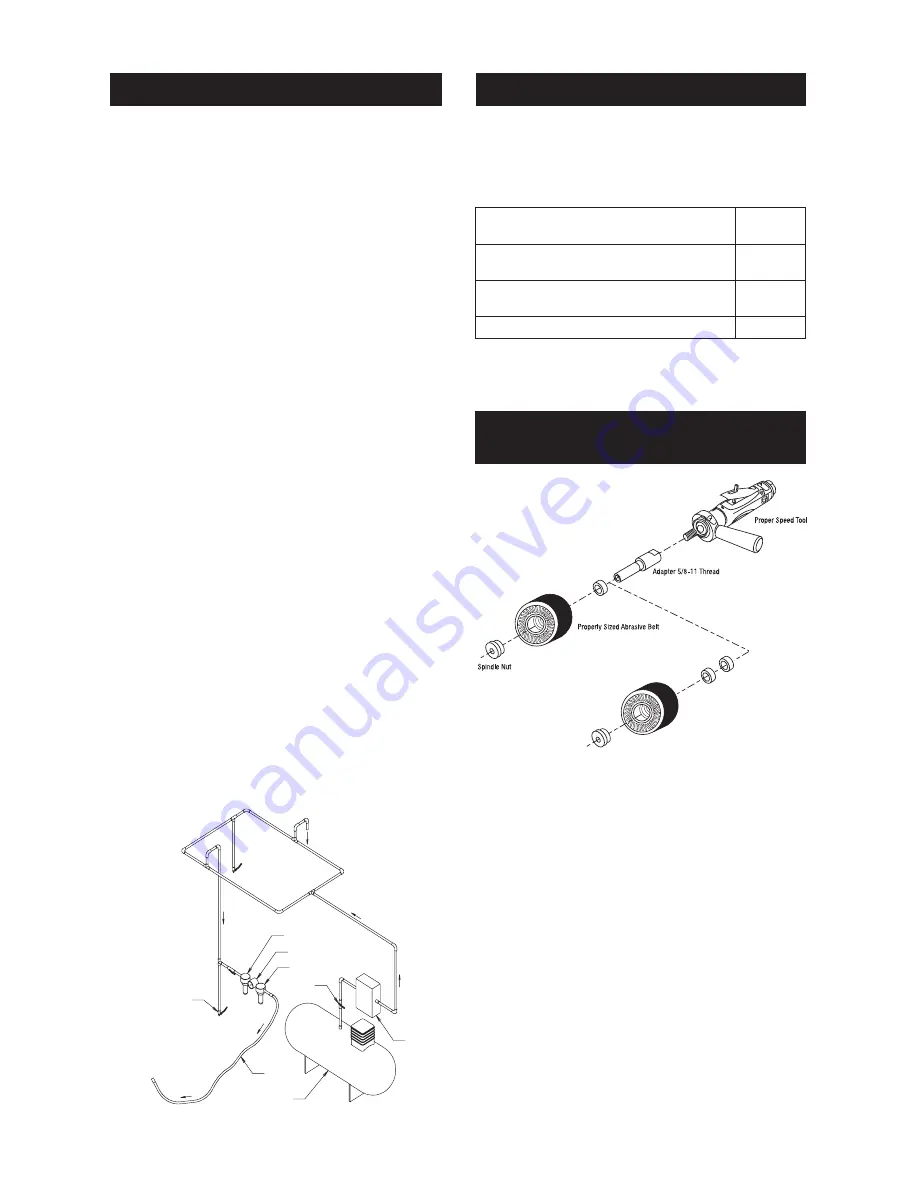

3M Inline Sander: Instructions for Mounting

and Dismounting Hardware

1. Disconnect air line from tool.

2. If already mounted, remove spindle mounted accessories and/or

abrasive product by using the wrenches supplied with the tool. Use the

wrenches to hold the tool spindle while turning the spindle extension

and/or mounting hardware counter clockwise.

3. Fully thread new spindle mounted accessories and/or abrasive product

onto the spindle in a clockwise rotation.

4. Secure all spindle mounted accessories and/or abrasive product with the

wrenches and tighten the spindle nut securely. Always use the correct

sized spindle accessories with the matching thread pitch and diameter.

An inadequately secured accessories and/or abrasive product could

loosen, bend or break causing damage to the tool and work piece and

possible injury to the operator or bystanders.

5. After the spindle accessories and/or abrasive product have been

mounted, inspect them to ensure they are free of debris and

undamaged.

6. Re-connect air line, position tool in a safe location, and test for any

unusual noise or vibration which may be caused by damaged or

improperly mounted accessory and/or abrasive product.

Note: During the above steps, ensure that all hardware and abrasive

products are mounted concentrically on the supporting accessory.

Accessory Description

Part

Number

3M™ Rubber Slotted Expander Wheel, 5 in x 3 ½ in x

5

/

8

Arbor Hole (for 3 ½ in x 15 ½ in belts)

28348

3M™ Rubber Slotted Expander Wheel, 3.4 in x 3 in x

5

/

8

Arbor Hole (for 3 in x 10

11

/

16

in belts)

28349

3M™ Wheel Adaptor Kit #3,

5

/

8

-11 External

45038

See 3M ASD Accessory catalogs 61-5002-8098-9 and 61-5002-8097-1 for

additional Accessories.

Spindle Nut

Properly Sized Abrasive Belt

3/8 in Spacers

3/8 in Spacer

Rubber Slotted

Expander Wheel

3.4 in x 3 in

Rubber Slotted

Expander Wheel

5 in x 3 1/2 in

Figure 1

Closed Loop Pipe System

Sloped in the direction of air flow

Drain Leg

Ball Valve

To Tool Station

Filter

Drain Valve

Regulator

Lubricator

Ball

Valve

Ball Valve

Air Flow

Air Dryer

Air Compressor

and Tank

Air Hose

To Coupler

at or near Tool