3

WORKING WITH 3D MODELS

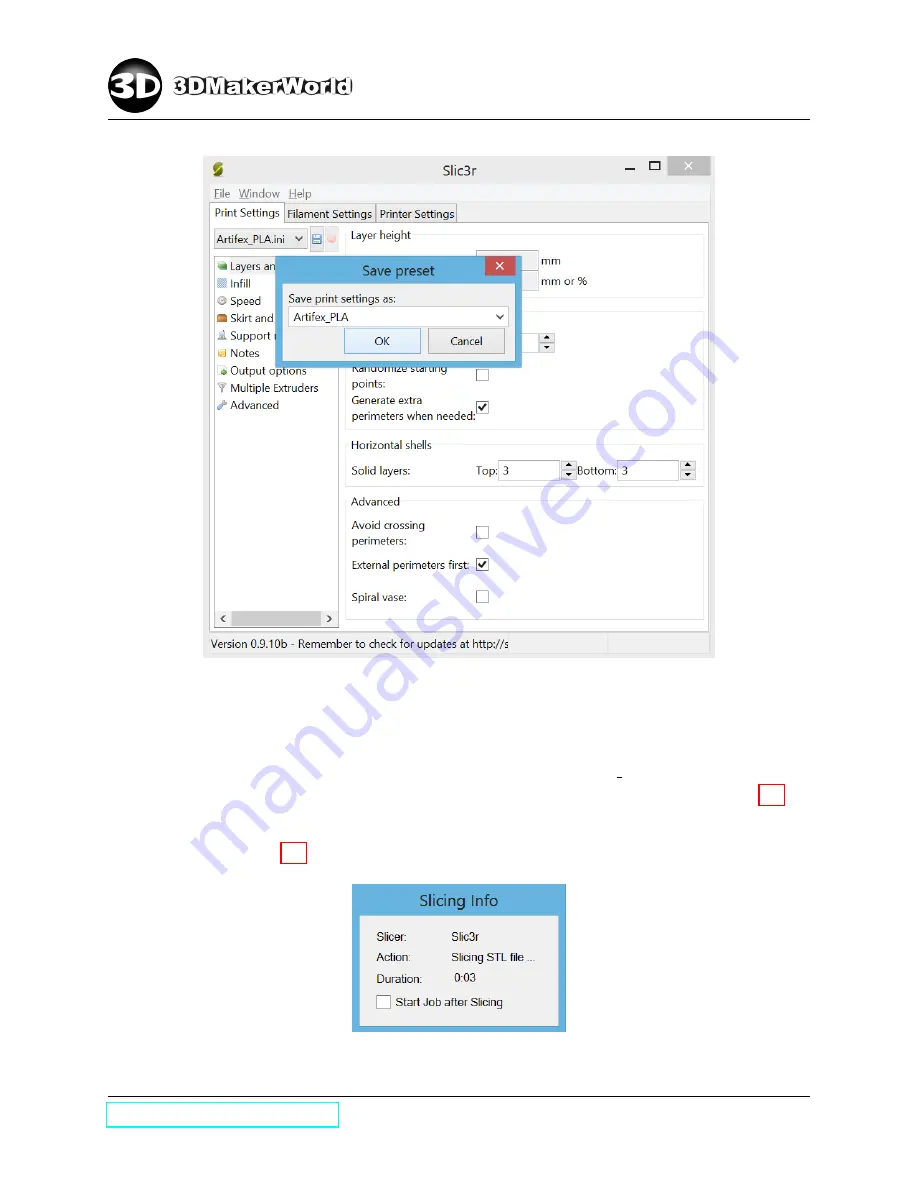

Figure 3.5: Saving print settings in Slic3r

3.2.3

Slicing 3D models

•

On the Slicer page of Repetier-Host interface, select “Artifex PLA” for Print Settings,

Printer Settings, and Filament Settings (Extruder 1) in Slic3r section. (Figure 3.2)

•

Click the “Slice with Slic3r” button, and a window will pop up showing the slicing

progress (Figure 3.6).

Figure 3.6: Slicing information window

48