3D Systems, Inc.

6

Blended Material Bin:

Material which is a combination of used material and fresh material is stored for production use in

this hopper . The system handles this automatically .

Used Material Bin:

Material which has gone through the system is stored here for production use . The used material is

reclaimed through the sifter .

See letter ‘F’ below

.

Fresh Material Input:

Fresh material is loaded at this location . The user must scan the RFID tag on the container across

the RFID Reader

(See letter ‘I’ below)

to open the doors .

Breakout Controls:

This roller switch allows the user to turn the sifter on and off .

Reject Chute:

Spent material (as determined by the user) is loaded into the reject chute .

Sifter:

The user removes the parts from the print cake in the breakout area and places the material for reuse into the

sifter . After sifting, the material will be transported to the used material bin .

Breakout Area:

The print cake is brought here using the

Part Transfer Cart Assembly

.

Thermocouples:

Two temperature gauges for the print cake used to determine whether or not the print cake has cooled

sufficiently to break out the parts.

Nitrogen Blanket:

This lid is placed on top of a filled print cake cylinder to control the cooldown of the print cake using

nitrogen .

A

B

C

D

E

F

G

H

I

J

I

G

H

F

E

D

C

K

L

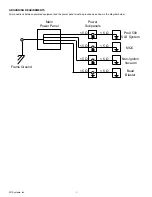

MQC System – Front View

ProX Material Quality Control (MQC) System

Supplied by

: 3D Systems

Installed by

: 3D Systems

The ProX MQC System is an integral part of the ProX 500 3D Printer . It is responsible for properly regulating and controlling the SLS

material used to print parts with the ProX 500, as well as breaking out parts from the print cake . Up to two printers can be used with a

single MQC System .

B

A