3D Systems, Inc.

INSTALL ELEVATOR FORKS AND PRINT PLATFORM

1 .

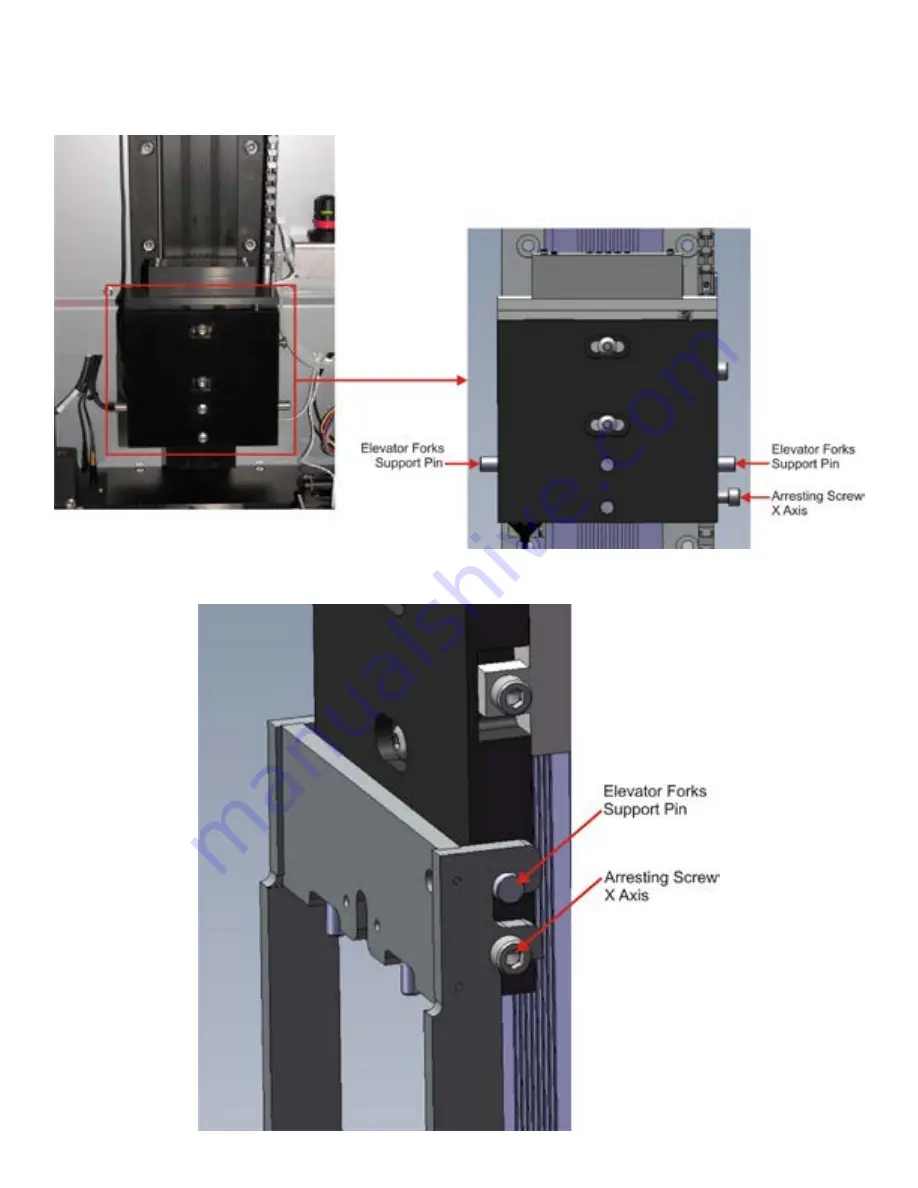

The figure below shows a detailed view of the elevator block. The elevator forks are installed on the elevator block and supported

by the elevator forks support pins (left and right side) .

2 . Install the elevator forks onto the elevator block as shown . Do not tighten the arresting screw at this time .

50

Summary of Contents for ProJet 6000

Page 1: ...User Guide Original Instructions ProJet 6000 3D Professional Printer ...

Page 15: ...3D Systems Inc Item P N Description Qty Label 8 19984 001 00 Heat Hazard Sticker 3 15 ...

Page 16: ...3D Systems Inc 16 ...

Page 23: ...3D Systems Inc Material Cart with Bottle Holder Extended 23 ...

Page 46: ...3D Systems Inc 3 Press Yes The ProJet 6000 will then display the opening screen 46 ...

Page 55: ...3D Systems Inc 7 After logging in the Status screen is displayed initially 55 ...

Page 71: ...3D Systems Inc EC DECLARATION OF CONFORMITY 8 71 ...