3

© Copyright 2017 Zoeller

®

Co. All rights reserved.

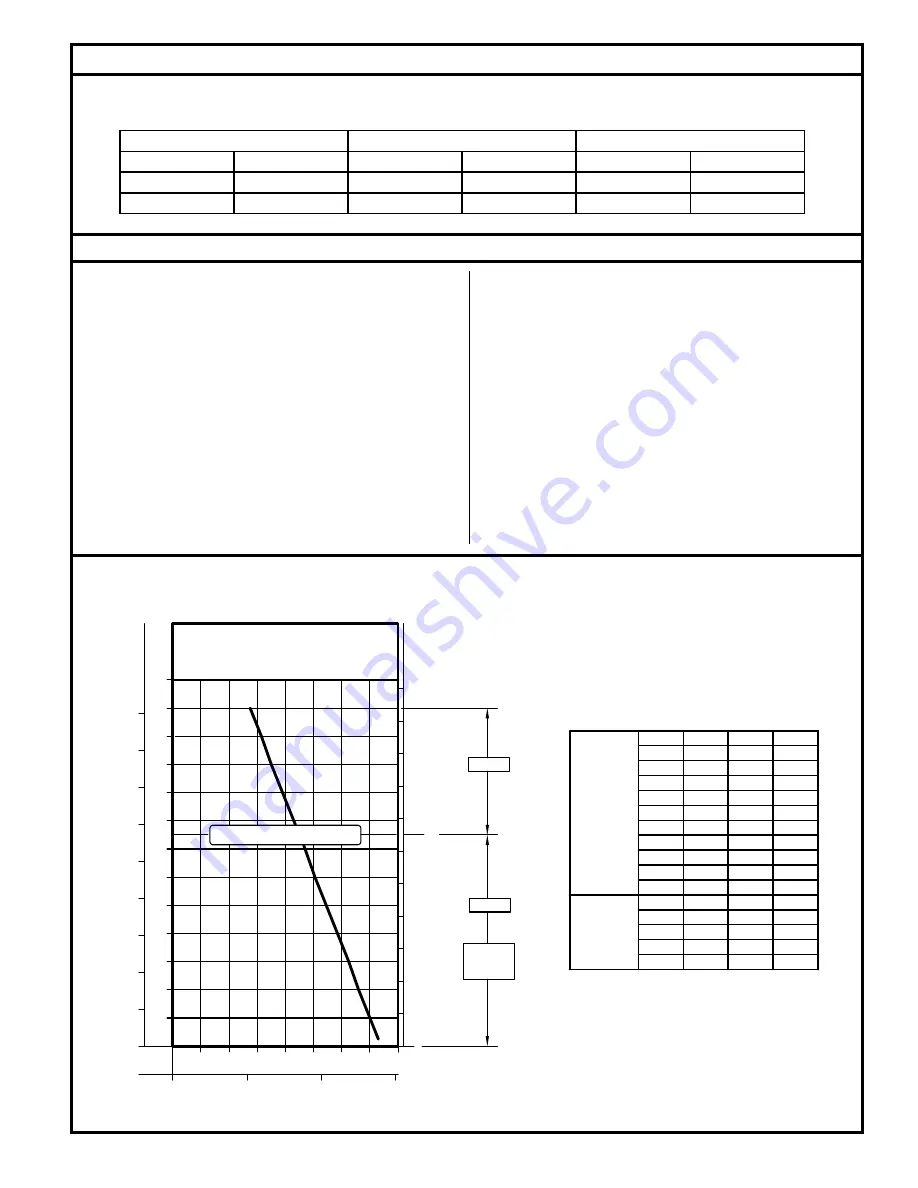

Recommended Limits of Application for Progressing Cavity Grinder Pumps

Simplex Station

Duplex Station

Model

HP

Homes

GPD

Homes

GPD

810

1

1

400

2

800

815

2

1

400

2

800

These recommended application limits are for pump stations pumping to a gravity main. Low-pressure collection systems should be designed with

a pump located at each house. For applications where a lift station would handle more than 2 homes, consider the 840 or 71 Series grinder pump.

For applications where a lift station would handle more than 60 homes, a solids handling type pump should be considered.

General Information

FIGURE 1.

PROGRESSING CAVITY

GRINDER PUMP DESCRIPTION

1. Pumps are constructed of class 30 cast iron protected with powder

coated epoxy for long life when pumping sewage in submersible

applications. The cutter assembly is comprised of stainless steel

components hardened to a value of 55-60 on the Rockwell C scale;

a star shaped cutter and a precision ground flat disk. Cutting action

takes place with the rotation of the cutter blades at 1750 RPM against

the stationary cutter plate (see page 7).

2. The cutter mechanism on the model 810 & 815 is single directional.

3. Pump motors are single phase. Single phase motors require a run

capacitor, which is mounted in the the upper cap of the pump (ref.

page 4). The units have an internal thermal overload.

4. The 810 & 815 progressing cavity grinder pumps are single seal.

5. The pressure relief valve provides motor protection under inadvertent

shut-off head condition.

6. A progressing cavity grinder pump is an intermittent duty pump designed

for pumping sanitary sewage. It is not a dewatering or trash pump.

FIELD ASSEMBLED INSTALLATION

1. Installation and piping instructions are included with the control panel, rail

system and basin instructions. If pump is being retrofitted to an existing

rail system, accessory parts may be required. Consult the factory and

advise make and model of rail system being used.

2. Refer to the appropriate Indoor/Outdoor prepackaged instructions for more

information on system installation.

3. All electrical connections including pump to control box and power supply

to control panels must comply with the “National Electrical Code” and

applicable local codes. Conduit and panel enclosure openings must have

a gas-tight seal. Installation of electrical panels and connections should

be made by a qualified licensed electrician.

4. A properly sized disconnect switch, supplied by others, shall be installed

on the service side of the pump and control panel.

5. When used in a pressure sewer, install an anti-siphon valve (see Fig. 5A).

018330

0

2

4

6

8

10

12

14

16

0

20

40

60

80

100

120

140

160

180

200

260

PUMP PERFORMANCE CURVE

MODEL 810/815

8

16

24

32

40

48

56

64

GALLONS

LITERS

METERS

FEET

TOT

AL

DYNAMIC HEAD

FLOW PER MINUTE

220

240

72

20

40

60

10

20

30

40

50

60

70

80

90

100

110

0

PSIG

TOT

AL

DYNAMIC HEAD

2 HP

1 HP

LOW PRESSURE SEWER

TYPICAL

OPERATING

RANGE

DESIGN PRESSURE (150 FT OR LESS)

TOTAL DYNAMIC HEAD/FLOW

PER MINUTE

MODEL

Feet

810

Meters

Gal.

Liters

MODEL

815

5

10

20

6.1

3.0

1.5

14.6

55

40

60

18.3

12.2

80

100

30.5

24.4

120

36.6

140

150

45.7

42.7

55

53

50

47

44

41

38

36

34

14.4

14.0

13.2

12.5

11.7

10.9

10.1

9.4

9.0

160

48.8

180

54.9

200

61.0

220

67.1

240

73.2

5.5

33

30

27

24

21

8.6

7.8

7.0

6.3