MAINTENANCE

ZIPPER MASCHINEN GmbH www.Zipper-Maschinen.at

43

ZI-HS13E / ZI-HS18EZ / ZI-HS25Z / ZI-HS25EZ

17

MAINTENANCE

W A R N I N G

Before carrying out any maintenance work, ensure that moving parts are stationary,

that the machine is disconnected from the mains supply and / or that the PTO shaft is

uncoupled.

17.1

Maintenance Schedule

Activity

Model

ZI-HS16E

ZI-HS16E

ZI-HS16E

ZI-HS16E

Check oil level

After each oil

change or every

8 oh*

After each oil

change or every

8 oh

After each oil

change or every

8 oh

After each oil

change or every

8 oh

Change

hydraulic oil

1 x per year

1 x per year

1 x per year

1 x per year

Change

gear oil

after 25 oh,

subsequently

every six months

or every 250 oh

after 25 oh,

subsequently

every six months

or every 250 oh

after 25 oh,

subsequently

every six months

or every 250 oh

*) oh … operating hours

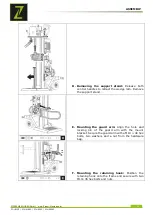

17.2

Replacing Oil

N O T I C E

Check the oil level regularly. Change the hydraulic oil completely at least once a year.

Always dispose of used oil correctly and never throw it into household waste or

sewage!

The hydraulic system of the log splitter is a closed system with oil tank, oil pump and control

valve. The oil should be changed completely once a year.

The following hydraulic oils are recommended for the hydraulic transmission system of the log

splitter:

Shell Tellus 22

Mobil DTE 11

Aral Vitam GF 22 or

BP Energol HLP-HM 2

If the oil level is too low, the oil pump can be damaged,

whereas overfilling can lead to overheating of the

hydraulic system. Therefore check the oil level regularly

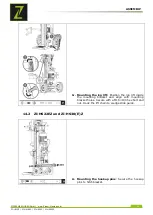

with the dipstick - see picture on the left!