A

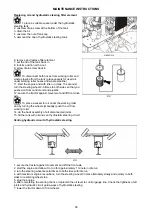

Lower draw bar with CBM hooks

65

Lower draw bar with slipping out end pieces

65

Accumulator battery

75

Accumulator battery maintenance

76

Acquaintance with the tractor

25

Adjusting clutch pedal

98

Adjustment

97

Adjustment of toe-in of the wheels of the front driving axle

68

After starting the engine

79

After wirk with front implements and in case of cooler

clogging

22

Aggregation with trailer and semitrailer

51

Air condition maintenance

95

Air Filter Maintenance

88

Air system tightness inspection

94

Air-condition filtration elements

95

Alternator

76

Alternator maintenance

76

Anti-freezing solution for filling tires

73

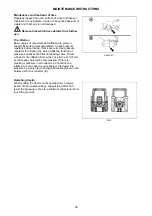

Automatic mouth of the CBM stage hitch

50

Auxiliary hydraulic switchboard control

32

B

Ballast weights

71

Ballast weights in front of bonnet grill

71

Basic service information

75

Battery disconnector

34

Battery disconnector

75

Bearing capacity of rear tires

101

Before starting the engine

79

Before you start the engine

37

Bleeding the Heating System

91

Bottom rear window

26

C

Cab air condition

30

Cab heating

29

Cab heating registers

29

Cartridge Replacement in the Fine Fuel Filter

87

Cartridge Replacement in the Raw Fuel Filter

87

Clearance-circle and turning circle diameter

102

Connecting and disconnecting quick couplings of trailer

hydraulic brakes

44

Connecting machines and tools to External hydraulic circuit

62

Coolant replacement

92

Cooling system

21

D

Dashboard

30

Detaching tractor

96

Differential lock

32

Differential lock

42

Direction indicator switch

28

Draining liquid from tires procedure

72

Draining oil from engine

85

Draining the condensate from air collector

95

Drive away

39

Drive of agricultural machinery

53

Drive of machines with greater inertia masses

56

Driver´s seat

27

Driving operation

12

Driving operation

37

Driving with front drive axle engaged

42

E

Electric installation

75

Engine heating

38

Engine oil level

21

Engine Performance Limitation

39

External hydraulic circuit

60

Extrernal hydraulic circuit control elements

60

F

Filling tires with liquid procedure

72

Filling, controlling and draining hole of oil of front drive axle

94

Filling, controlling and draining hole of oil of front wheels

reducers

94

Filtration elements cleaning

95

Fire prevention principles

13

Fixed and free position of lower hydraulic draw bars

64

Flat belt drive tension of accessories

97

Foot brakes pedals

42

Free (floating) position

58

From 100 hours of operation

47

Front bonnet opening

85

Front drive axle control

42

Front drive axle control lever

34

Front drive axle fenders

68

Front hook

49

Front passenger´s seat notification

15

Front tires steerability

100

Front wheels toe-in

68

Front windshield wiper and washer

28

Fuel

82

Fuel Filtering

86

Fuel system leaks

21

Fuel system venting

88

Fuel tank

35

Fuse box

77

G

Gear shifting

40

Gear shifting from higher to lower gears

41

Gear shifting from lower to higher gears

41

Gear shifting lever

33

Gear system drain plug

93

General principles of new tractor run-in in first 100 hours of

operation

47

General safety regulations

11

H

Headlights switch

28

Heating filtration element

94

Hinged lid

26

Hitches

22

Hitches

63

Hydraulic brakes of trailers

44

Hydraulic control

32

Hydraulic control panel

57

Hydraulic equipment

57

Hydraulic sensitivity system control

58

Hydraulic system

57

Hydraulic system

101

Hydrostatic steering

22

Hydrostatic steering failure warning signalization

45

CH

Change of front wheels track with front drive axle

67

Checking amount of oil in hydrostatic steering tank

89

Checking oil levels in engine

85

Checking the oil in gear box, final drive housing and rear

axle

92

I

If engine does not start

38

Immediately after start

38

Important notification

45

In first 10 hours of operation

47

Independent PTO shaft revolutions

102

Information Display - Basic View

31

Information Display - Fault Notifications

31

Information Display - Maintenance Notifications

31

Internal hydraulic circuit control elements

57

L

Leaving the tractor

45

Lights adjustment in cab roof check

78

Lights adjustment in tractor´s grill

78

Lights adjustment in tractor´s grill check

78

Limiting draw bars

64

Liquid for the cooling system of the tractors

82

Location of serial numbers

9

M

Main technical parameters

99

Main tractor's parameters (mm)

99

Maintenance and treatment of tires

96

Maintenance instructions

85

Making front wheels stable

71

Manipulation with starter

38

INDEX

103

Содержание MAJOR

Страница 1: ...60 80 Tractor is Zetor Since 1946 OPERATOR S MANUAL MAJOR 01 2014...

Страница 3: ...2...

Страница 8: ...Clearance circle and turning circle diameter 102 Index 103 CONTENTS 7...

Страница 9: ...NOTES 8...

Страница 21: ...NOTES 20...

Страница 25: ...NOTES 24...

Страница 37: ...NOTES 36...

Страница 47: ...NOTES 46...

Страница 49: ...NOTES 48...

Страница 53: ...NOTES 52...

Страница 67: ...NOTES 66...

Страница 71: ...NOTES 70...

Страница 75: ...NOTES 74...

Страница 85: ...NOTES 84...

Страница 106: ...NOTES 105...

Страница 108: ...Made in EU www zetor com zetor zetor com...