48

Mod. KERA rev 01

Cleaning and Routine Maintenance

translated from the original text

EN

Room sensor

The room sensor is placed at the

back of the boiler and detects the

temperature of the room where it is

located.

Glow plug

The glow plug ignites the flame in-

side the brazier. The pellets are lit

when the glow plug overheats and

the air inside the combustion cham-

ber heats up.

Manual rearm thermostat

The thermostat is triggered by de-

activating operation of the auger in

case of tank overtemperature.

Pressure switch

The pressure switch measures the

negative pressure inside the boiler

and, since it is connected to the pel-

let loading motor, if this is not suf-

ficient for proper operation of the

product, the feed is interrupted.

It is a mechanical safety device for

detecting the correct draught of the

flue.

H2O probe

The water temperature probe is

located inside the boiler and con-

nected to the board to manage op-

eration of the boiler itself.

Pressure gauge

The pressure gauge detects pres-

sure inside the boiler and system.

Circulator

The circulator installed on the re-

turn enables water circulation ad-

justment inside the system.

Expansion vessel

The expansion vessel is a hydraulic

component, which is there to con-

tain circuit pressure variations, thus

preventing dangerous surges that

would otherwise have to be ab-

sorbed by the pipes and the rest of

the system.

5 ROUTINE CLEANING

All the parts must be cleaned up when the

stove is completely cold and unplugged.

The product does not require much mainte-

nance if certified quality pellets are used.

5.1

DAILY/WEEKLY CLEANING

5.1.1

CLEANING BEFORE EACH IGNITION

Clean all ashes and build-ups in the brazier which could ob-

struct the air vents. If the pellets run out, unburnt pellets could

accumulate inside the brazier. Always empty the brazier from

residue before each ignition.

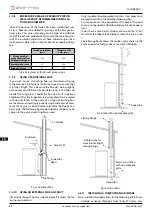

fig. 36 clean brazier dirty brazier

REMEMBER THAT ONLY IF THE BRAZIER IS POSITIONED

AND CLEANED PROPERLY CAN IGNITION AND IDEAL OP-

ERATION OF YOUR PELLET STOVE BE GUARANTEED.

To clean the brazier efficiently, remove it from its seat and

completely clean all the holes and the grating at the bottom.

When good quality pellets are used, it is normally sufficient

to use a brush to restore the brazier to ideal operating condi-

tions. After a long idle period, using a vacuum cleaner with

a long tube, remove any pellet residue sitting for a long time

as it could have absorbed humidity thus modifying its original

characteristics and becoming unsuitable for combustion.

5.1.2

CHECK EVERY 2/3 DAYS

Clean and empty the ash pan, paying attention to hot ashes.

Only if the ashes are completely cold may you use a vacuum

cleaner to remove them. In that case, use a vacuum cleaner

suitable to vacuum particles of a certain size. Your own experi-

ence and the quality of the pellets will determine the frequen-

cy of cleaning. It is however recommended not to go be-

yond 2 or 3 days. When the operation is finished, reinsert the

ash pan below the bracer making sure it is properly in place.

Содержание KERA

Страница 2: ......

Страница 82: ...82 Mod KERA rev 01 KERA fig 42 KERA dimens es totais dimensions d encombrement dimen siones totales...

Страница 84: ...84 Mod KERA rev 01...

Страница 85: ......

Страница 86: ......

Страница 87: ......

Страница 88: ......