61

63

60

COMP2 ON

COMP2 TRIP

INDIVIDUAL COMP. ON/OFF/TRIP

COMP 2

TO ECB1

X2

55

COMP 1

X1

TO ECB1

COMP1 ON

COMP1 TRIP

41B

FR2

2

56

41A

FR1

58

2

UNIT ON

43

1

45

AR1

UNIT TRIP

44A

UNIT TRIP

46

44

2

UNIT ON / OFF

UNIT STATUS (VFC) INDICATION CONNECTION

AR9-1

6D

6E AR8-1

C

NC

P

1

NO

LPS5

Y2 [LVTB]

31B

AR9

HGS CONNECTION W/O COMP UNLOADER

Y1 [LVTB]

31A

AR8

HGS

2

6C

17A

C [LVTB]

17A

X2

70

COMP4 ON

COMP4 TRIP

71

TO ECB2

COMP3 TRIP

41D

FR4

COMP3 ON

65

66

COMP 3

TO ECB2

X1

41C

FR3

73

2

68

2

COMP 4

44C

44B

73

B

72

B

71

B

73

A

71

A

72

A

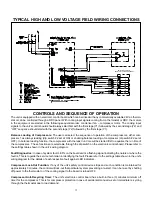

CONTROLS

TO ATB

230Vac

HTR1

HTR2

INFAN

(in cond. unit)

(in cond. unit)

TO ECB

30

29

14

HC2

28

AFS

BMC

19

BM CONTROL

STG1 COOLING

STG1 HEATER

STG2 HEATER

STG2 COOLING

( NOTE 8)

(REMOVE JUMPER JP)

Y1

W2

W1

Y2

R

C

G

TB1 (ECB)

Y1

W2

W1

Y2

24Vac

R

C

G

LVTB

T3

F

T2

F

T1

F

(Stg. 1 Heating)

T1

H

T2

H

T3

H

(Stg. 2 Heating)

FROM T'STAT CONTROLLER OR DDC

(by others)

W2

W1

Y2

Y1

G

C

R

68

SWITCHING CONTACTS

69

70

OPTIONAL AHU INTER-CONNECTION

(POWER AND CONTROL FOR ELECTRIC HEATER &BLOWER MOTOR)

TO POWER SUPPLY

L1

L3

L2

TO POWER SUPPLY

L2

L1

L3

TO POWER SUPPLY

L1

C

L2

C

L3

C

L2

L1

L3

YR3

Y4

Y3

STG3 COOLING

STG4 COOLING

YR3

Y3

Y4

LPS5

C

COMPRESSOR UNLOADER CONNECTION (OPTIONAL)

C

LPS6

COMP 2

TO ATB

28B

28B

COMP 1

TO ATB

28A

28A

P

NC

6B

NC

P

NC

NO

C

LPS10

P

5B

NO

2

P

NO

LPS9

C

6A

5A

NO

NC

2

AR9-1

HGS CONNECTION WITH COMP UNLOADER

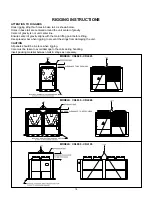

COMP1 SHOULD ALWAYS BE LEAD COMPRESSOR.

DIP SWITCH S2 SHOULD ALWAYS BE SET TO "ON" POSITION.

NC

P

NOTE:

6E

NO

LPS5

C

AR8-1 6D

6C

HGS

2

5A

LPS11

NO

C

LPS12

C

NC

NO

UL3 & UL 4 CONNECTION APPLICALBLE FOR COMP WITH 3 STEPS

P

CAPACITY UNLOADING.

NOTE

TO ATB

COMP 4

28D

C

28B

LPS8

P

NO

NC

6B

P

6C

NC

5B

2

NO

NC

TO ATB

28C

COMP 3

LPS7

P

28C

C

5C

2

UL3

UL7

UL8

UL4

UL1

UL2

UL6

UL5

FR1-1

FR3-1

FR2-1

FR4-1

CC2A

-2A

CC4A

-2

A

AR1-1A

FR3-2A

FR1-2A

FR2-2A

CC1A

-2

A

FR4-2A

CC3

A-

2A

OLR-1

HTR2

HTR1

CB12

HC2

HC1

CB11

BMC

OLR

CB

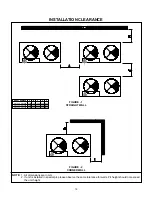

CONDENSER FAN MOTOR POWER, CONTROL CONNECTIONS : STANDARD AND FAN CYCLING OPTION (12FANS)

35

I

11

2

FM1

36

A

35

A

37

E

FM5

36

E

35

E

37

A

37

B

35

B

36

B

FM2

FM11

36K

35G

35

F

36

F

37

F

FM6

35K

37G

36G

FM7

37H

36H

37K

35H

FM8

FM12

36

L

35

L

37

L

FMC2

10

1

10

0

L1

CB7

CB6

FMC1

10

2

104

103

105

L3

L2

L3

L2

L1

CB9

10

7

10

6

FMC5

10

8

L1

L3

L2

CB9

11

0

10

9

11

1

FMC6

L3

L1 L2

36

J

35

J

37

I

36

I

FM9

37

J

FM10

CB10

FMC7

11

3

11

4

FMC8

13A

13G

12G

TO ECB1

OUTFAN 1

OUTFAN 2

TO ECB1

FM7

T.O.P

12A

FM1

T.O.P

12K

FMC5

12K

2

FM11

T.O.P

FM5

T.O.P

12E

12E

FMC1

2

12-FAN MOTOR LAYOUT

CDL195

CO

NT

RO

L

PAN

EL

FM9

T.O.P

1

12I

FMC5A-1

13I

FMC7

2

FMC1A-1

1

FMC3

T.O.P

12C

13C

2

FM3

35

C

36

C

37

C

FM3

FMC3

CB8

L3

L2

L1

FMC4

FM4

37

D

36

D

35

D

FM2

TO ECB2

12B

OUTFAN 1

T.O.P

12F

13B

12D

FM6

FMC2

12F

T.O.P

2

FMC2A-1

1

TO ECB2

FM4

FMC4

13D

T.O.P

2

OUTFAN 2

12H

T.O.P

FM12

13H

T.O.P

FM8

12L

12L

FMC6

2

12J

FMC6A-1

1

13J

T.O.P

FM10

FMC8

2

11

5

11

6

11

7

REFER OPTIONAL FCS CONNECTION BELOW.

**

FMC1A-1

1

FM3

FMC3

13C

T.O.P

2

SEE FCS CONN BELOW

SEE FCS CONN BELOW

SEE FCS CONN BELOW

SEE FCS CONN BELOW

10A

11A

FCS1

P

12C

1

FMC2A-1

P

12D

FCS3

10B

11B

13D

T.O.P

FMC4

2

FM4

10C

10D

1

1

FMC6A-1

FMC5A-1

12J

FCS4

11D

P

P

FMC8

13J

FM10

T.O.P

12I

FCS2

11C

13I

T.O.P

FM9

FMC7

2

2

16

TYPICAL SCHEMATIC WIRING DIAGRAM

MODELS: CDL110 - CDL195

Power supply: 380/415V-3Ph-50Hz

NOTES

1. ANY WIRE REPLACEMENT SHOULD BE OF 90

0

C

OR ITS EQUIVALENT.

2. USE COPPER CONDUCTOR WIRES ONLY.

3. POWER MUST BE SUPPLIED TO CRANKCASE

HEATER FOR MINIMUM OF 12 HOURS PRIOR TO

SYSTEM START UP.

IF POWER IS OFF 6 HOURS OR MORE, CRANK-

CASE HEATER MUST BE ON FOR 12 HOURS BE-

FORE OPERATING THE SYSTEM.

FAILURE TO FOLLOW THESE INSTRUCTIONS

MAY RESULT IN COMPRESSOR DAMAGE.

4. FUSED DISCONNECT SWITCH OR CIRCUIT

BREAKER TO BE PROVIDED BY CONSUMER

WITH RATING AS RECOMMENDED BY COOLINE.

5. COMPRESSOR MOTORS ARE PROVIDED WITH SSPS OR IN-

TERNAL LINE BREAK THERMAL OVERLOAD PROTECTION.

6. USE DISCONNECT TAB OR SPLICE ONLY WHERE

EVER REQUIRED FOR EXTENSION OF ORIGINAL WIRE.

7. USE SHIELDED TYPE CABLE, #18 AWG (MIN.) FOR LVTB

FIELD WIRING. GROUND CONNECT AT BOTH ENDS.

8. COOLING OUTPUT SIGNAL FROM CONTROLLER

SHOULD FOLLOW THE SEQUENCE:

ON SEQUENCE - Y1 - Y2 - Y3 - Y4.

OFF SEQUENCE - Y4 - Y3 - Y2 - Y1.

9. AT COMP. LOCKOUT CONDITION (FAULT), VOLTAGE

ACROSS TERMINAL X1, X2 OF ECB & ATB #2 IS

230VAC. ALSO, COMP. LOCKOUT LIGHT (RED) IS ON.

+

LEGEND

AR

AUXILIARY RELAY

ATB

AUXILIARY TERMINAL BLOCK

BM

BLOWER MOTOR

BMC

BLOWER MOTOR CONTACTOR

CC

COMPRESSOR CONTACTOR

CCA

CC AUXILIARY CONTACT

CB

CIRCUIT BREAKER

C. HTR

CRANKCASE HEATER

COMP/C COMPRESSOR

DDC

DIRECT DIGITAL CONTROLLER

ECB

ELECTRONIC CONTROL BOARD

F

FUSE

FCS

FAN CYCLING SWITCH

FM

FAN MOTOR (CONDENSER)

FMC

FAN MOTOR CONTACTOR

FR

FAULT RELAY

HGS

HOT GAS BYPASS SOLENOID

HPS

HIGH PRESSURE SWITCH

HVTB

HIGH VOLTAGE TERMINAL BLOCK

JP

JUMPER

L1

LINE 1

L2

LINE 2

L3

LINE 3

LPS

LOW PRESSURE SWITCH

LVTB

LOW VOLTAGE TERMINAL BLOCK

LUG

LUG GROUND

NTB

NEUTRAL TERMINAL BLOCK

OLR

OVER LOAD RELAY

P

PRESSURE

PDS

PUMP DOWN SOLENOID

SSPS

SOLID STATE PROTECTION SYSTEM

TOP

FM THERMAL OVERLOAD PROTECTION

TRANS TRANSFORER

T'STAT THERMOSTAT

VFC

VOLT FREE CONTACT

YR

COOLING RELAY

FIELD WIRING

TERMINAL BLOCK OR TERMINATION POINT

SPLICE-CLOSED END

JUNCTION OF WIRES, CONNECTED

CROSSING OF WIRES, NO CONNECTION

_ _ _

Содержание Cooline CDL Series

Страница 8: ...7 DIMENSIONS NOTE All dimensions are in mm CDL 020 CDL 025 CDL 030 CDL 035 CDL 040 ...

Страница 9: ...8 DIMENSIONS NOTE All dimensions are in mm CDL 050 CDL 055 CDL 065 ...

Страница 11: ...10 DIMENSIONS NOTE All dimensions are in mm CDL 135 CDL 160 ...

Страница 12: ...11 DIMENSIONS NOTE All dimensions are in mm CDL 195 ...