-3-

■

EPDT

-

183b

■

4.

Installation

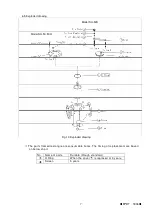

4.1 Example of piping

Fig.

4

Example of Piping

(1)

Installation of pressure gauges at either end of the strainer will enable you to tell the clogging

condition of the strainer by looking at the loss of pressure.

(2)

Upon installation, make sure that cover

②

comes at the top.

(3)

If you are using the strainer outdoors, please coat the strainer for rust prevention.

4.2 Warning and cautions upon installation

Warning

(1) As this product is heavy, please use a hanging device to securely support the product upon

connection to the piping. For hanging Models SU-50S and , you may use eye nuts

⑥

. (Please

refer to Chart 2 for the weight of each product.)

※

Please note that falling of the product can result in injuries.

Cautions

(1)

Please confirm that the direction of the fluid flow and the arrow on the product coincide

before installing the product.

※

The product will not function if it is installed in the wrong direction.

(2)

Please support the piping and fix on the product securely.

※

The product may deform from too much stress from the piping.

(3)

Upon installation, please secure sufficient space as shown in Fig. 5 and 6 for maintenance

and inspection (including cleaning of the screen).

※

You will be unable to maintain (including cleaning of the screen) and inspect the product if

there is not enough space.

(4)

Upon piping, please make sure that unnatural force, bending, or vibrations will not be

transmitted to the product.

※

Inadequate piping can result in leakages.

(5)

Please make sure that the connections with the piping are secure.

※

Inadequate connections can result in physical damages due to fluid outflow caused by

vibrations and other reasons.

※

Inadequate connections can result in fluid outflow.

Fig. 5 Space required above the

strainer for removal of the screen

Fig.

6

Space required beside the strainer for

removal of the screen (for SU-50S only

)