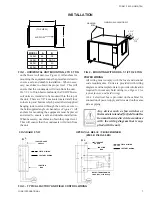

GENERAL DIMENSIONS

MODEL

UNIT CABINET

BLOWER OUT-

LET

RETURN DUCT

CONNECTION

FILTER SIZE

MANIFOLD

CONNECTION

AA

BB

CC

EE

FF

GG

HH

90YSHW4

52-1/2

54

27

16-3/8

19-1/8

45

25-1/4

24 X 25 (2)

1-1/8 ODS.

120YSHW4

52-1/2

57

32

16-3/8

19-1/8

48

30-1/4

26 X 29 (2)

1-3/8 ODS.

180YSHW4

56-1/2

66

39-1/2

16-3/8

44-3/4

57

37-3/4

20 X 36.5 (2)

1-3/8 ODS.

240YSHW4

62-1/2

66

52

16-3/8

44-3/4

57

50-1/4

20 X 49 (3)

1-3/8 ODS.

90YSHW6

52-1/2

54

27

16-3/8

19-1/8

45

25-1/4

24 X 25 (2)

1-1/8 ODS.

120YSHW6

52-1/2

57

32

16-3/8

19-1/8

48

30-1/4

26 X 29 (2)

1-3/8 ODS.

180YSHW6

56-1/2

66

39-1/2

16-3/8

44-3/4

57

37-3/4

20 X 36.5 (3)

1-3/8 ODS.

240YSHW6

62-1/2

66

52

16-3/8

44-3/4

57

50-1/4

20 X 49 (3)

1-3/8 ODS.

4 ROW COIL

FILTER SIZE

LIQUID

(SWEAT)

SUCTION

(SWEAT)

90YSHX4

52-1/2

54

27

16-3/8

19-1/8

45

25-1/4

24 X 25 (2)

5/8 ODS.

1-1/8 ODS.

120YSHX4

52-1/2

57

32

16-3/8

19-1/8

48

30-1/4

26 X 30 (2)

1/2 ODS.

7/8 ODS.

180YSHX4

56-1/2

66

39-1/2

16-3/8

44-3/4

57

37-1/4

37-1/2 X 20 (3)

5/8 ODS.

1-1/8 ODS.

240YSHX4

62-1/2

66

52

16-3/8

44-3/4

57

50-1/4

50 X 20 (3)

5/8 ODS.

1-1/8 ODS.

FIG 5 - DIMENSIONS FOR 7-1/2 - 20 TON UNITS

INSTALLATION

EE

BB

FF

3.50

GG

HH

3.50

3.50

2.00

L

AIR FLOW

3.50

1.00

AIRFLOW

AA

CC

YORK INTERNATIONAL

6

FORM 115.22-NOM5 (704)