352867-UIM-A-0208

6

Unitary Products Group

4.

Total system charge = item 1 + item 2 + item 3.

5.

Permanently stamp the unit data plate with the total amount of

refrigerant in the system.

Use the following charging method whenever additional refrigerant is

required for the system charge.

If a calibrated charging cylinder or accurate weighing device is avail-

able, add refrigerant accordingly. Otherwise, model-specific charging

charts are provided on the access panel of the unit.

SUPERHEAT CHARGING METHOD -

PISTON INDOOR

1.

Set the system running in cooling mode by setting the thermostat

at least 6°F below the room temperature and operate system for at

least 10 – 15 minutes.

2.

Refer to the technical guide for the recommended airflow and ver-

ify indoor airflow (it should be about 400 SCFM per ton)

3.

Measure and record the outdoor ambient (DB) temperature and

the suction pressure at the suction service valve.

4.

Using the charging chart located on the unit, find the intersection

of the outdoor ambient dry bulb and the suction pressure obtained

in step 3. This is the recommended suction tube temperature at

the service valve.

5.

Measure and record the suction tube temperature at the service

valve and compare to the recommended temperature obtained in

step 4.

6.

Add charge if the measured suction temperature in step 5 is above

the recommended value. Remove / recover refrigerant if the mea-

sured suction temperature is below the recommended value.

SUBCOOLING CHARGING METHOD - TXV INDOOR

For cooling operation, unless otherwise specified, the default subcool-

ing is 10°F.

1.

Set the system running in cooling mode by setting the thermostat

at least 6°F below the room temperature and operate system for at

least 10 – 15 minutes.

2.

Refer to the technical guide for the recommended indoor airflow

and verify it is correct (it should be about 400 SCFM per ton).

3.

Measure and record the indoor wet bulb (WB) and the outdoor

ambient dry bulb (DB) temperature.

4.

Using the charging chart located on the unit, find the intersection

of the indoor wet bulb and the outdoor dry bulb. This is the recom-

mended liquid pressure (and subcooling value).

5.

Measure and record the pressure at the liquid valve pressure port

and compare to the value obtained in step 4.

6.

Add charge if the measured liquid pressure is lower than the rec-

ommended value. Remove / recover charge if the measured liquid

pressure is above the recommended value.

Condenser subcooling is obtained by calculating the difference of the

saturated refrigerant temperature of the pressure measured at the liquid

base valve and the liquid tube temperature as measured at the liquid

base valve.

Subcooling Temp. (TC) = Saturated Temp. (TS) – Liquid Temp. (T)

Refrigerant charging should only be carried out by a qualified air

conditioning contractor.

Compressor damage will occur if system is improperly charged. On

new system installations, charge system per tabular data sheet for

the matched coil and follow guidelines in this instruction.

Example: The suction tube temperature listed on the table at the

intersection of the outdoor DB and the suction pressure is 63°. Tem-

perature of the suction tube at the service valve is 68°. It would be

necessary to add refrigerant to drop the suction tube temperature to

63°.

Example: The liquid pressure listed at the intersection of the indoor

WB and the outdoor DB 320 psig. Pressure at the liquid valve is 305

psig. It would be necessary to add refrigerant to increase the liquid

pressure to 320 psig.

IT IS UNLAWFUL TO KNOWINGLY VENT, RELEASE OR DIS-

CHARGE REFRIGERANT INTO THE OPEN AIR DURING

REPAIR, SERVICE, MAINTENANCE OR THE FINAL DISPOSAL

OF THIS UNIT.

WHEN THE SYSTEM IS FUNCTIONING PROPERLY AND THE

OWNER HAS BEEN FULLY INSTRUCTED, SECURE THE

OWNER’S APPROVAL.

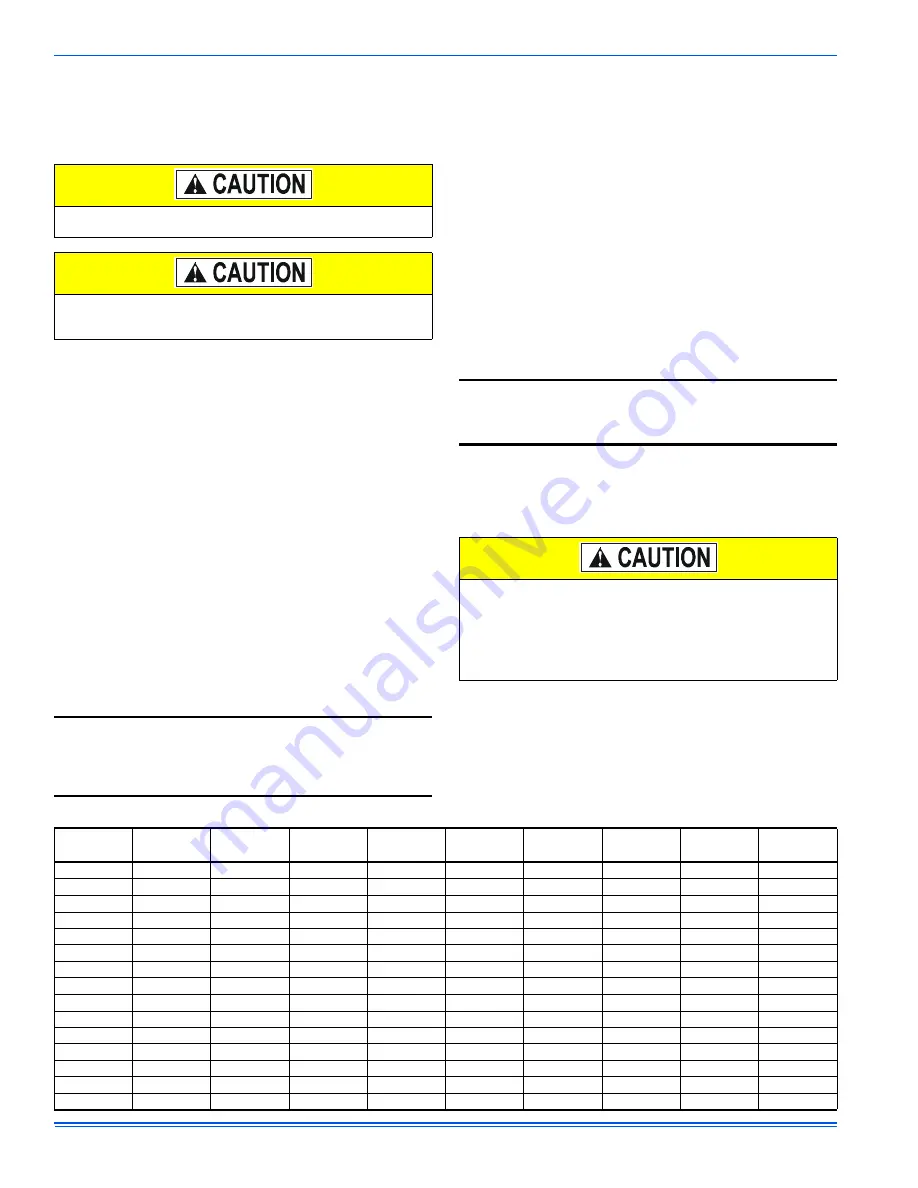

TABLE 2:

R-410A Saturation Properties

TEMP.

°

F

PRESSURE

PSIG

TEMP.

°

F

PRESSURE

PSIG

TEMP.

°

F

PRESSURE

PSIG

TEMP.

°

F

PRESSURE

PSIG

TEMP.

°

F

PRESSURE

PSIG

45

130

60

170

75

217

90

274

105

341

46

132

61

173

76

221

91

278

106

345

47

135

62

176

77

224

92

282

107

350

48

137

63

179

78

228

93

287

108

355

49

140

64

182

79

232

94

291

109

360

50

142

65

185

80

235

95

295

110

365

51

145

66

188

81

239

96

299

111

370

52

147

67

191

82

243

97

304

112

375

53

150

68

194

83

247

98

308

113

380

54

153

69

197

84

250

99

313

114

385

55

156

70

201

85

254

100

317

115

391

56

158

71

204

86

258

101

322

116

396

57

161

72

207

87

262

102

326.

117

401

58

164

73

211

88

266

103

331

118

407

59

167

74

214

89

270

104

336

119

412