P. 3

IM01C50C03-02EN

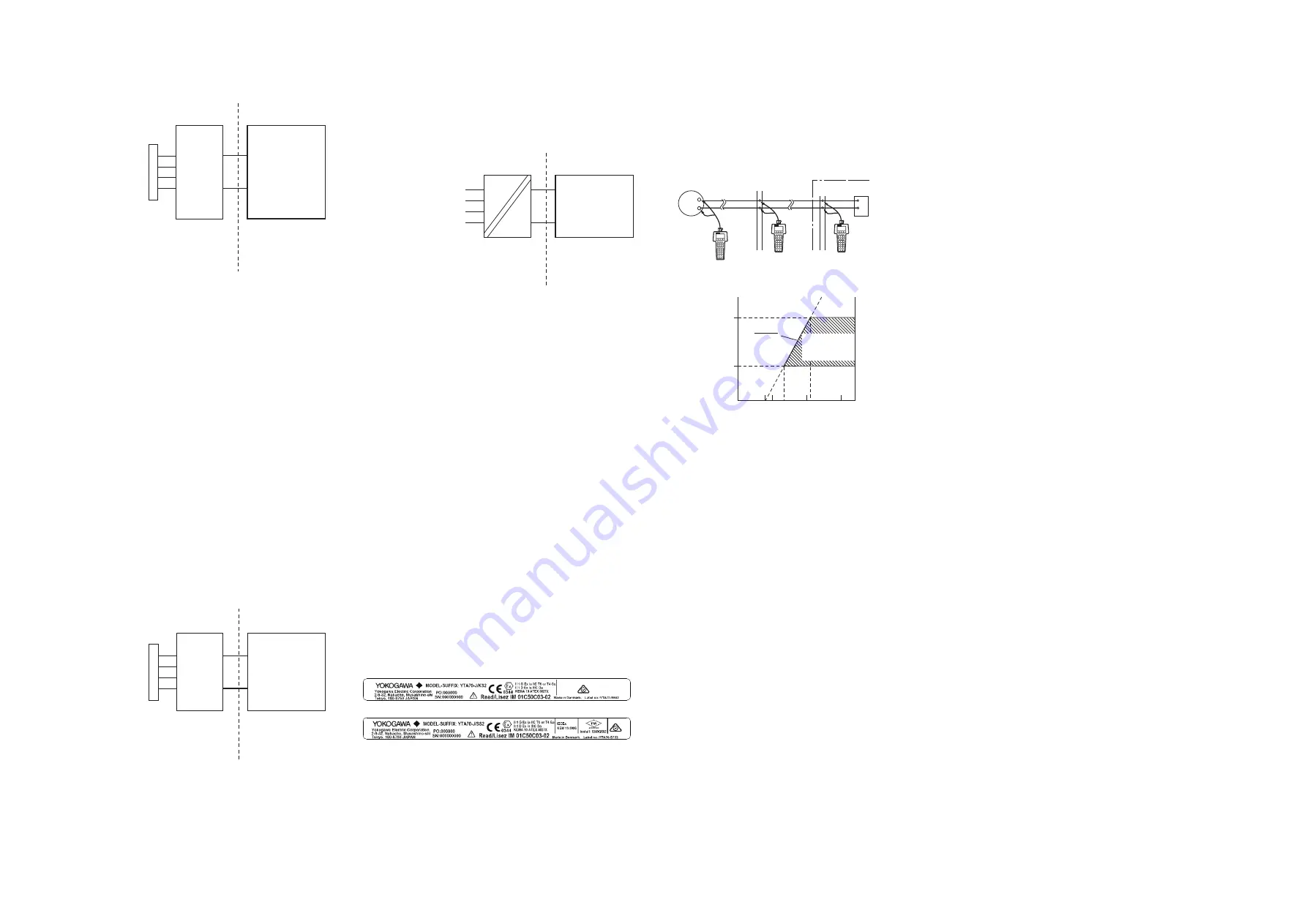

7.2 FM Intrinsically safe/Nonincendive model (/SS2)

Applicable Standard: Class 3600, Class 3610, Class 3611, Class 3810,

ANSI/ISA-60079-0, and ANSI/ISA-60079-11

Installation diagram

Non-hazardous Location

Hazardous (Classified) Location

YTA70

F04E.ai

[ Intrinsically safe ]

Class I,Division1, Groups, A,B,C,D

Class I, Zone 0, IIC

Terminal 3,4,5,6

Vt or Uo: 9.6 V

It or Io: 28 mA

Pt or Po: 67.2 mW

Ca or Co: 3.5 uF

La or Lo: 35 mH

Terminal: 1 , 2

Vmax or Ui: 30 V

Imax or Ii: 120 mA

Pmax or Pi: 0.84 W

Ci: 0 µF

Li: 10 µH

Associated Apparatus

or Barrier

with

entity Parameters:

UM ≤ 250V

Voc or Uo ≤ Vmax or Ui

Isc or Io ≤ Imax or Ii

Po ≤ Pi

Ca or Co ≥ Ci + C cable

La or Lo ≥ Li + L cable

This device must not be

connected to any

associated apparatus

which uses or generates

more than 250 VRMS

Ambient temperature limits

T4: -40 to +85 deg. Celcius

T6: -40 to +60 deg. Celcius

1 +

2 -

6

5

4

3

sensor

The entity concept

The Transmitter must be installed according to National Electrical Code (ANSI-

NFPA 70) and shall be installed with the enclosure, mounting, and spacing

segregation requirement of the ultimate application.

Equipment that is FM-approved for intrinsic safety may be connected

to barriers based on the ENTITY CONCEPT. This concept permits

interconnection of approved transmitters, meters and other devices in

combinations which have not been specifically examined by FM, provided

that the agency’s criteria are met. The combination is then intrinsically safe,

if the entity concept is acceptable to the authority having jurisdiction over the

installation.

The entity concept criteria are as follows:

The intrinsically safe devices, other than barriers, must not be a source of

power.

The maximum voltage Ui(V

MAX

) and current Ii(I

MAX

), and maximum power

Pi(Pmax), which the device can receive and remain intrinsically safe, must be

equal to or greater than the voltage (Uo or V

OC

or V

t

) and current (Io or I

SC

or I

t

)

and the power Po which can be delivered by the barrier.

The sum of the maximum unprotected capacitance (C

i

) for each intrinsically

device and the interconnecting wiring must be less than the capacitance (C

a

)

which can be safely connected to the barrier.

The sum of the maximum unprotected inductance (L

i

) for each intrinsically

device and the interconnecting wiring must be less than the inductance (L

a

)

which can be safely connected to the barrier.

The entity parameters Uo,V

OC

or V

t

and Io,I

SC

or I

t

, and C

a

and L

a

for barriers

are provided by the barrier manufacturer.

F05E.ai

[ Nonincendive ]

Non-hazardous Location

Hazardous (Classified) Location

YTA70

Class I,Division2, Groups, A,B,C,D

Class I, Zone 2, IIC

Associated Apparatus

or Barrier

Voc or Vt ≤ Vmax

Ca ≥ Ci + C cable

La ≥ Li + L cable

This device must not be

connected to any

associated apparatus

which uses or generates

more than 250 VRMS

Ambient temperature limits

T4: -40 to +85 deg. Celcius

T6: -40 to +60 deg. Celcius

1 +

2 -

6

5

4

3

sensor

Terminal: 1 , 2

Vmax: 35 V

Ci: 0 μF

Li: 10 µH

7.3 IECEx Scheme Intrinsically safe model (/SS2)

For safe installation of YTA70 the following must be observed. The module shall

only be installed by qualified personnel who are familiar with the national and

international laws, directives and standards that apply to this area.

Year of manufacture can be taken from the first two digits in the serial number.

Certificate No.: IECEx KEM 10.0086

Applicable Standard: IEC 60079-0:2007-10, IEC 60079-11:2006,

IEC 60079-26:2006, IEC 61241-11:2005

Non-hazardous Area

Hazardous Area

F14E.ai

[ Installation diagram ]

Zone 0, 1, 2, 20, 21, 22

T4: -40 ≤ Ta ≤ 85°C

T6: -40 ≤ Ta ≤ 45°C

Terminal: 1, 2

Ui: 30 VDC

Ii: 120 mA

Pi: 0.84 W

Li: 10 μ H

Ci: 1.0 nF

YTA70

6

5

4

3

Terminal: 3, 4, 5, 6

Uo: 9.6 VDC

Io: 28 mA

Po: 67 mW

Lo: 35 mH

Co: 3.5 μF

Barrier

1 +

2 -

Installation notes

For installation in a potentially explosive gas atmosphere, the following

instructions apply:

The sensor circuit is not infallibly galvanic isolated from the supply output

circuit. However, the galvanic isolation between the circuits is capable of

withstanding a test voltage of 500Vac during 1 minute.

The transmitter shall be mounted in an enclosure form B according to

DIN43729 or equivalent that is providing a degree of protection of at least

IP20 according to EN60529 that is suitable for the application and correctly

installed.

If the enclosure is made of aluminium, it must be installed such, that even in

the event of rare incidents, ignition sources due to impact and friction, sparks

are excluded.

If the enclosure is made of non-metallic materials, electrostatic charging shall

be avoided.

For installation in a potentially explosive dust atmosphere, the following

instructions apply:

The transmitter shall be mounted in a metal enclosure form B according to

DIN43729 or equivalent, that is providing a degree of protection of at least

IP6X according to EN60529 that is suitable for the application and correctly

installed.

Cable entries and blanking elements shall be used that are suitable for the

application and correctly installed.

For an ambient temperature ≥60°C, heat resistant cables shall be used with a

rating of at least 20 K above the ambient temperature.

For installation in mines the following instructions apply:

The transmitter shall be mounted in a metal enclosure that is providing a

degree of protection of at least IP6X according to EN60529, and is suitable for

the application and correctly installed.

Cable entries and blanking elements shall be used that are suitable for the

application and correctly installed.

7.4 Name Plate

F06E.ai

[/KS2]

[/SS2]

8. HART Communication

8.1 Connection and Requirements

A standard HART communicator can be used for programming the YTA70. The

HART communicator must be loaded with the appropriate DDL driver for YTA70.

Minimum loop resistance is 250Ω. If the receiving equipment has a lower

resistance, a serial resistor must be inserted to communicate with the HART

communicator.

[Connection]

HART

communicator

HART

communicator

HART

communicator

YTA70

Distributor

Control room

Terminal board

Relaying

terminals

F07E.ai

+

−

[Communication requirement]

(Ω)

Power supply voltage E (V DC)

600

250

R

8.0 13.8

21.8

External

load

resistance

E-8

0.0236

R=

Digital

Communication

range

F08E.ai

35.0

8.2 Switching HART Protocol Revision

HART protocol revision of the transmitter can be selectable from 5 or 7. The HART

protocol revision is set and shipped as specified in the order. To change the HART

protocol revision after shipment, follow the procedure shown below. Please note

that selecting HART 5 will change the model code of YTA70-J to YTA70-E on the

configuration tool.

1) Call up the parameter for protocol revision change.

Device setup -> Detailed setup -> Device information -> Revision numbers ->

Chng universal rev

2) Activate the “Chg universal rev” method.

3) Select OK for confirmation message screen twice.

4) Select a HART protocol revision 5 or 7.

5) Enter a write protect password. The default password is “********”, eight

asterisks.

6) The device will automatically restarts with a new HART protocol revision.

Restart the HART configuration tool for parameter settings.