IM 05C01E02-01E 4th Edition Mar. 14, 2016-00

4

■

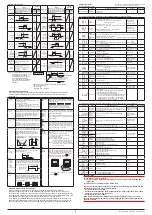

Alarm Function List

Alarm type

Action

“Opn” and “Cls” indicate that the relay

contact is opened and closed; “(on)” and

“(off)” indicate that the lamp is on and off;

and white triangles indicate temperature

control setpoints.

Alarm

type code

Alarm type

Action

“Opn” and “Cls” indicate that the relay

contact is opened and closed; “(on)” and

“(off)” indicate that the lamp is on and off;

and white triangles indicate temperature

control setpoints.

Alarm

type code

Closed

contact

during

alarm

Open

contact

during

alarm

Closed

contact

during

alarm

Open

contact

during

alarm

No alarm

OFF

De-

energized

on deviation

low limit

Hysteresis

Temperature setpoint

Deviation setting

Measured value

Opn (on)

Cls (off)

6

16

(See

note.)

PV

high limit

Hysteresis

Alarm setting

Measured value

Opn (off)

Cls (on)

1

11

(See

note.)

PV

low limit

Hysteresis

Alarm setting

Measured value

Opn (off)

Cls (on)

2

12

(See

note.)

Deviation

high and

low limit

Hysteresis

Hysteresis

Temperature setpoint

Deviation setting

Measured value

Cls

(on)

Opn

(off)

Cls

(on)

7

17

(See

note.)

Deviation

high limit

Opn (off)

Hysteresis

Cls (on)

Measured value

Temperature setpoint

Deviation setting

3

13

(See

note.)

Deviation

within

high- and

-low-limit

Hysteresis

Hysteresis

Temperature setpoint

Measured value

Opn (off)

Opn (off)

Cls (on)

Deviation setting

8

18

(See

note.)

Deviation

low limit

Cls (on)

Hysteresis

Opn (off)

Measured value

Temperature setpoint

Deviation setting

4

14

(See

note.)

De-

energized

on PV

high limit

Hysteresis

Opn (on)

Cls

(off)

Alarm setting

Measured value

9

19

(See

note.)

De-

energized

on deviation

high limit

Measured value

Temperature setpoint

Hysteresis

Deviation setting

Opn (on)

Cls (off)

5

15

(See

note.)

De-

energized

on PV

low limit

Hysteresis

Cls (off)

Opn (on)

Alarm setting

Measured value

10

20

(See

note.)

Fault

diagnostics

output

The contact is closed at input

burnout.

21

Heater

disconnection

alarm

The controller starts measuring the current from

the heater disconnection detector when 100

milliseconds have passed after turning on the

output.

Cls

(on)

Heater current

Alarm setting

Opn (off)

25

FAIL

output

The output contact is opened in the

following events:

• Program error • A/D converter error

• ROM error

• RJC error

• RAM error

• EEPROM error

• power failure

22

Note: The alarms numbered 1 to 10 have

no waiting action, while alarms 11

to 20 have a waiting action.

The waiting action turns off the

PV and deviation alarms that

occur from the start of the control

operation until a stable state is

reached.

Abnormal

Alarm output = ON

Normal

Low limit alarm

setpoint

In this area, the alarm output is turned

off even when a measured value falls

below the low limit alarm setpoint.

Time

Power-on

°C

Taken as

normal.

Waiting action

The waiting action is effective in the following cases where;

• The power is turned on

• SP is changed

• The alarm type is changed

■

Description of Parameters

This section describes the parameter functions specific to the UT130 temperature controllers.

(The functions described in other sections of this manual and the general functions are not

discussed.)

Parameter

Function

Parameter

Function

Control

mode

Select one from the following:

a. Dynamic auto tune control (SLF) (See note)

b. PID control (PID)

c. On/off control (ONF)

Note: Dynamic auto tune control is not available

for heating/cooling control.

Read the section below this table to find out more

about dynamic auto tune control.

PV input

bias

This function adds a bias value to the measured

input value, and the result is used for display and

control computation.

PV value inside the controller

measured input value

PV bias

+

=

This function is useful for carrying out fine

adjustment when the PV value is within the

required accuracy but it differs from the value

obtained by other equipment.

CTL

BS

Manual

reset

You can set this parameter only for control without

an integral action (when registered as CTL=PID

and I=OFF). The controller outputs the manual

reset (MR) value when PV=SP. For example, if

you set MR=50%, the controller outputs (OUT)

50% when PV=SP.

Maximum/

minimum

value of

target

setpoint

range

Using the SPH and SPL parameters, you can limit

the setting range of the target setpoint (SP) within

the measured input range.

This function prevents SP from being mistakenly

set at too large or too small a value (beyond the

setting range).

MR

SPH,

SPL

Cooling-side

gain

For heating/cooling control, you can set the ratio

between the cooling-side output and heating-side

output.

For example, if you set COL=2.0 and the heating-

side output is 10% at a certain deviation (SP-PV),

then the cooling-side output will be 20% when the

cooling-side also reaches that deviation.

COL

Hysteresis

for

alarm 1

and 2

The alarms are output as relay outputs. Since a

relay has a limited life, excessive on/off actions will

shorten the life of the alarm. To prevent this, you

can set a hysteresis to prevent excessive on/off

actions for both alarm 1 and alarm 2.

Deadband

You can only set a deadband for heating/cooling

control. In a positive deadband, there are neither

heating-side nor cooling-side outputs. In a

negative deadband, there are both heating-side

and cooling-side outputs, which overlap each

other.

HYS

HYS

ON

OFF

ON

OFF

Deadband

DB (+)

Deadband

DB (+)

0

SP

PV

100%

100

0

SP

100

PV

100%

Cooling

side

Heating

side

100%

0%

1. When the deadband of a heating/

cooling type is positive

(Proportional band [P] control)

2. When both the heating and cooling

sides are under on-off control

HY1,

HY2

SUPER

function

selection

The SUPER function is effective in the following

cases:

a. An overshoot must be suppressed.

b. The rise-up time needs to be shortened.

c. The load often varies.

d. SP is changed frequently.

Note 1: The SUPER function will not work

when on/off control is selected, or I or D

constants is set at OFF in PID control.

Note 2: For some types of systems, the SUPER

function may not be so useful. If this is the

case, turn off the function.

DB

SC

Hysteresis

for

on/off

control

For on/off control (CTL=ONF), you can set a

hysteresis band around the on/off point (SP) to

prevent chattering.

On/off point (SP)

Hysteresis band

ON

OFF

Priority of

PV/SP

display

Since the UT130 controller has a single data

indicator, you can give display priority to either

PV or SP. The data which has the priority will be

displayed on the data indicator upon power-on

or when the operating display is resumed from a

parameter setting display using the

key

(by pressing for at least 3 seconds).

To switch the display between PV and SP,

press the key.

Displays SP

Displays PV

SP display lamp is on.

HYS

Control

output

/ cooling-

side

control

output

cycle time ]

The cycle time is the period of on/off repetitions of

a relay or voltage pulse output in time proportional

PID control. The ratio of the ON time to the cycle

time is proportional to the control output value.

Cycle time

t ON

t OFF

C o o l i n g - s i d e

control output cycle

time has the same

functions.

*

CT

CTC

DSP

PV input

filter

This function should be used when the PV display

value may fluctuate greatly, for example, when the

measured input signal contains noise. The filter

is of the first-order lag type, and FL sets the time

constant. If a larger time constant is set, the filter

can remove more noise.

Input

2-seconds filter

10-seconds filter

FL

■

What is Dynamic Auto Tune Control?

Dynamic auto tune control is one of the features offered by the temperature controller.

When the controller is turned on or the measured input value (PV) starts “hunting”, this mode of

control monitors the behavior of the PV and/or OUT (control output value) to automatically determine

the optimum PID constants. This means that the PID constants may be changed automatically. If this

is not desirable for your system, operate the controller in the normal “PID control”.

If you want to automatically determine the PID constants at the initial startup of the controller, first

define the target setpoint (SP) and then turn the controller off once and then back on again. Do not

use dynamic auto tune control for a system where there is interference or continual disturbances.

■

Parameter Lists

Numbers in ( ) are the parmeter setpoints that apply when the

communication function is used. Ex. OFF(0), ON(1)

(1) Target Setpoint (SP)

Code

Name

Setting range and unit

Default

User setting

(SP value display)

Target

setpoint

Minimum value (SPL) to maximum value (SPH) of target

setpoint range

Unit: °C/°F

SPL

(2) Operating Parameters: Parameters changed rather frequently during operation.

Code

Name

Setting range and unit

Default

User setting

A1

Alarm 1

setpoint

■

PV alarm Unit: °C/°F

Setting range: minimum value to maximum value of

measured input range

■

Deviation alarm Unit: °C/°F

Setting range: –100 to 100% of the measured input range

span

■

Heater disconnection alarm Unit: A (ampere)

Setting range: OFF(0), 1 to 80

(can be set for the alarm 1 setpoint only)

Max. value of

measured input

range (PV alarm)

A2

Alarm 2

setpoint

Min. value of

measured input

range (PV alarm)

HC

Heater

disconnection

current

measured

value

“HC” is not a parameter to be set. The current value (0 to 80) of heater disconnection

detector is displayed. Unit: A (ampere)

Settings: When the display value is –––, the heater current is not being measured.

CTL

Control mode

ONF(0): On/off control

PID(1): PID control

SLF(2): Dynamic auto tune control (cannot be set for heating/

cooling control)

SLF(2) : standard

type;

PID(1) : heating/

cooling type

AT

Auto-tuning

OFF(0): Stop auto-tuning(AT)

ON(1): Start auto-tuning(AT)

OFF(0)

P

Proportional

band

1°C /°F to the temperature that corresponds to 100% of the

measured input range span

5% of measurd input

range span

I

Integral time 1 to 999 seconds;

OFF(0): no integral action

240 seconds

D

Derivative

time

1 to 999 seconds;

OFF(0): no derivative action

60 seconds

MR

Manual reset -19.9 to 99.9 % : Standard type

-100 to 100 % : Heating/cooling type

50.0% : standard

type; 0.0% : heating/

cooling type

COL

Cooling-side

gain

0.01 to 9.99 times

1.00 times

DB

Dead band

■

PID control Unit: °C/°F

Setting range: –(proportional band setting) to +(proportional

band setting)

■

On/off control Unit: °C/°F

Setting range: –50 to +50% of measured input range span

3.0% of measured

input range span

HYS

Hysteresis for

on/off control

0°C /°F to the temperature that corresponds to 100% of the

measured input range span

0.5% of measured

input range span

CT

Control

output cycle

time

1 to 240 seconds

30 seconds

CTC

Cooling-side

control output

cycle time

1 to 240 seconds

30 seconds

FL

PV input filter OFF(0), 1 to 120 seconds

OFF(0)

BS

PV input bias –100 to 100% of measured input range span

0% of measured

input range span

LOC

Key lock

0: No key lock

1: Prevents operations from being changed except for the

changing of SP in the operating display

2: Prevents all parameter changing operations

–1: Set “-1” to enter the setup parameter setting display. But

if “LOC=1 or 2” is already set, the parameter value can

not be changed by setting “LOC=-1” only. To change

the parameter value, set “LOC=0” at first (for disabling

keylock), then set “LOC=-1” once again.

0

(3) Setup Parameters: Parameters rarely changed in normal use after once having been set.

Code

Name

Setting range and unit

Default

User setting

IN

Measured

input type

1 to 7, 12, 13, 15 to 19, 31 to 37, 42, 43, 45 to 48 (See

measured input range code list.) OFF(0): No input

(If no input type is specified at the time of ordering, you must

set the input type.)

OFF(0), or the input

range code specified

with order

SPH

Maximum

value of

target

setpoint

range

(SPL+1°C) to the maximum value of the measured input

range; Unit: °C/°F

Maximum value

of measured input

range

SPL

Minimum

value of

target

setpoint

range

Minimum value of measured input range to (SPH–1°C)

Unit: °C/°F

Minimum value of

measured input

range

AL1

Alarm 1 type OFF(0), 1 to 22 (See the alarm function list.)

25 (for the heater disconnection alarm /HBA option only)

1

(PV high limit alarm)

AL2

Alarm 2 type

OFF(0), 1 to 22 (See the alarm function list.)

2

(PV low limit alarm)

HY1

Alarm 1

hysteresis

0 to 100% of measured input range span

Unit: °C/°F

0.5% of measured

input range span

HY2

Alarm 2

hysteresis

SC

SUPER

function

ON(1): Uses the SUPER function

OFF(0): Does not use SUPER function

Note: Not displayed when on/off control

OFF(0)

DR

Direct/

reverse

action

0: Reverse action

1: Direct action

Note: Not displayed for heating/cooling type

0

DSP

Priority of PV/

SP display

0: Displays PV

1: Displays target setpoint (SP)

0

PSL

Protocol

selection

0: PC-link communication

1: PC-link communication with sum check

2: Ladder communication

3: MODBUS in ASCII mode

4: MODBUS in RTU mode

0

ADR

Controller

address

1 to 99

However, the number of controllers that can be connected per

host device is 31 at the maximum.

1

BPS

Baud rate

2.4(0): 2400 bps

4.8(1): 4800 bps

9.6(2): 9600 bps

9.6(2)

PRI

Parity

NON(0): Disabled

EVN(1): Even parity

ODD(2): Odd parity

EVN(1)

STP

Stop bit

1 or 2 bits

1 bit

DLN

Data length

7 or 8 bits

• 8 bits when ladder, MODBUS (RTU)

• 7 bits when MODBUS (ASCII)

8 bits

IMPORTANT

To use dynamic auto tune control,

(1) be sure to turn on the final control element, such as a heater, before starting the

control, and

(2) make sure the controlled loop is a closed loop.

If you do not follow these precautions, improper PID constants may be written into the

controller. If this occurs, carry out the following:

• Set the parameter CTL at PID.

• Set the PID constants at the factory-set defaults (P = (upper range-limit - lower range-

limit) × 5%; I = 240 sec.; and D = 60 sec.)

• Set the parameter CTL at SLF.

If the control still doesn’t work properly, stop using the dynamic auto tune control

function. Change the parameter CTL setting to PID and execute auto-tuning to obtain

the PID constants.