A. Allow the heating element to heat up for appr-

oximately 3 minutes, then, rub gentlythe deso-

ldering nozzle inside the brass wool.

B. When the oxidation is partially removed, cont-

inue applying solder onto the desoldering noz-

zle while rubbing it until the nozzle is complet-

ely coated with solder. If the nozzle is too sev-

erely oxidized beyond cleaning, replace it with

a new one.

2. DO NOT use metal files to remove the oxidation

on the desoldering nozzle. If the nozzle deforms

or rusts, replace the desoldering nozzle with a

new nozzle.

3. DO NOT apply excessive force on the desolderi-

ng nozzle when operating. Doing this will NOT

IMPROVE the heat transfer but damage the de-

soldering nozzle instead.

4. After every operation, clean the desoldering no-

zzle, then tin the nozzle with a new layer of sol-

der to prevent oxidization.

5.

Nozzle Cleaning

Allow the heating element to heat up for appro-

ximately 3 minutes, then, use the cleaning pin

to clean the nozzle.

desolderingiron's power cord to an electrical

outlet, allow the iron to heat up for approxima-

tely 3 minutes, then use the nozzle cleaning pi-

ns to clean the inner hole of the heating eleme-

nt.

It’s a must to melt all the solder inside the inner

hole before cleaning. Replace the heating elem-

ent if the cleaning pin CANNOT be put through

the inner hole.

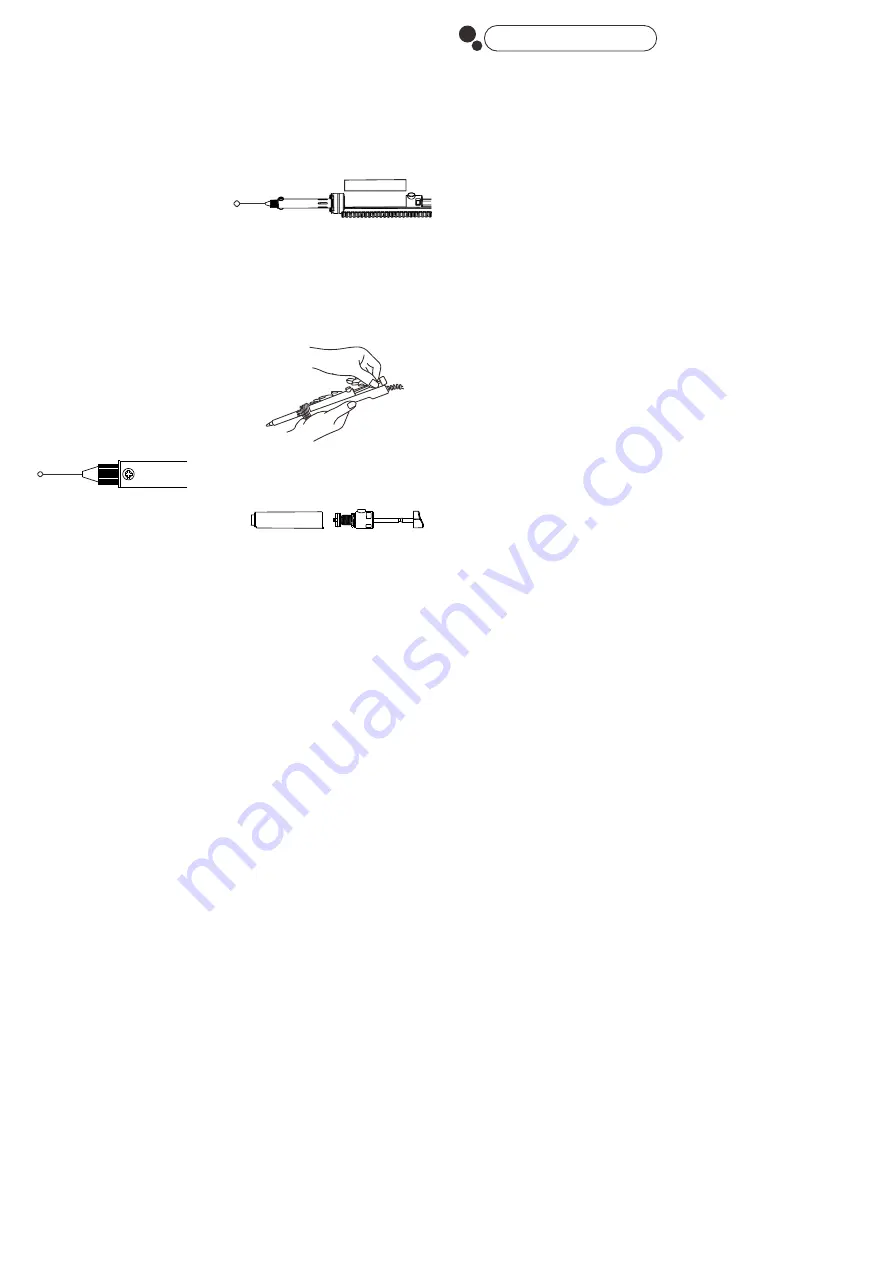

7.

Storage Tube Cleaning

Turn OFF the power, and wait until the storage

tube has cooled completely before cleaning the

storage tube.

V. TROUBLESHOOTING GUIDE

The heating indicator turns ON but the heating el-

ement is not heating up – This is an indication that

the heating element is faulty. To resolve this, you

need to replace the heating element.

2. Separate the storage tube and clean

the scrap solder out

1. Lift up and pull out the storage tube

created that the nozzle cannot heat up proper-

ly to melt the solder and do the tinning. Howe-

ver, the actual temperatures of both the heati-

ng element and nozzle are high. In such an ins-

tance, please do not increase the temperature

value confusedly but use a metal wool ball to

remove the oxidization following the steps bel-

ow:

05

06

07

6.

Heating Element Cleaning

Remove the nozzle, tin storage tube when the

heating element has cooled. Then, connect the