YewdaleDefiant

®

Manufacturing instructions

Part no: 2004

6

1

.

Ensuring the head box/fascia profile is square within the saw, cut the head

box to size.

2

.

Ensuring the head box cover is square within the saw, cut the head box to

size making sure there is no distortion.

N.B It is critical that the profile is cut square to enable the cover to close.

3

.

Cut the barrel, bottom bar, fabric, side channels and PVC insert to size.

4

.

File all aluminium cuts and cut a small V-shape in the top of the PVC tracker

profile to assist in fabric location.

5

.

Weld a pocket at the bottom of the fabric to fit the fabric insert (see

diagram on Page 4). Weld zips onto fabric both sides of the fabric to match

the drop of the blind.

6

.

Attach the fabric to the barrel making sure the narrow end of the fabric is

attached and central to the barrel.

7

.

Attach the bottom bar to the fabric using the fabric insert. Once complete

insert the end caps.

8

.

Insert the transition plates into the head box and attach the end plates

using 933010 screws.

9

.

Cut the chain to length and attach to control mechanism.

10

.

Making sure the control is on the correct side, insert the control mechanism/

pin end into the barrel and place the barrel and fabric into the head box.

11

.

Using the punch provided, punch a hole in the head box cover to enable the

chain to enter/exit the head box:

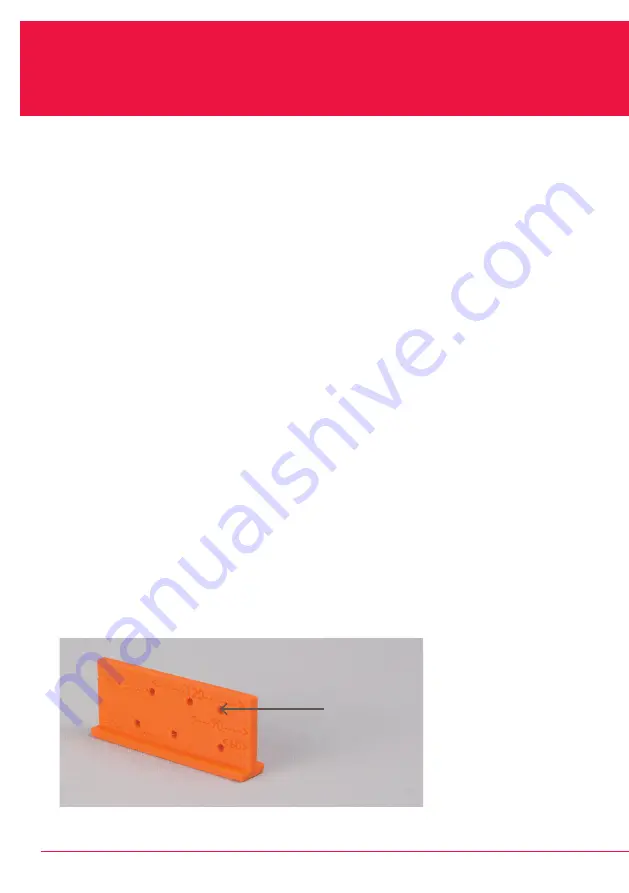

a) Place the

template on the

control side of head

box cover and mark

the hole for the

chain guide using

a pencil (template

should be pushed

firmly against the lip

on the cover).

C40-60T Cassetted Blinds:

Use this

hole on the

template

Manufacturing Instructions

YewdaleDefiant

®

cassetted blinds (C40-60T)