RECEIVING

When the absorption chiller is delivered to

the job site, inspect for any transit damage. Report

any damage to the carrier and note on the bill of

lading. Notify the Yazaki Sales Representative or

Distributor before proceeding with the installation

of a damaged unit.

UNIT NAMEPLATE

The UNIT NAMEPLATE is located on the

lower right hand side of the front panel on each

absorption chiller unit. Check that the model

number, flow rates and electrical specifications

are compatible with the system design and

services available.

RIGGING

Remove the crate from the absorption chiller.

When access is restricted, it may be necessary to

remove the skid to reduce overall height.

Each unit has four eye bolts in the top panel

which should be used for lifting.

Care should be taken at all times during

rigging and handling of the absorption chiller to

avoid damage to the panels and external pipe

connections. DO NOT DROP.

Attach a sling to the four eye bolts in the top

panel as shown in Fig.1 and ensure that the rope

angle is greater than 60

O

to the horizontal plane.

Always carry the absorption chiller in a NEAR

VERTICAL POSITION. DO NOT TIP OVER.

The dry weight and overall dimensions are

shown in PHYSICAL DATA on Page 3 as a guide

for rigging (add 6 in. to overall height for skid).

When moving the absorption chiller, check

that the route is accessible. The minimum access

dimensions for a skid mounted chiller are shown

in Fig.2.

LOCATION

Yazaki absorption chillers have a weather-

proof cabinet suitable for either indoor or outdoor

installation.

Select a location with due consideration for

the proximity of the cooling tower, chilled/hot

water coils and service access.

The minimum space requirements, shown in

Fig.3, must be provided around and above each

chiller for installation and service access.

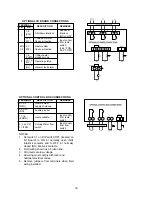

Fig. 1 RIGGING

MODEL

DIMENSION

WFC-SC10

WFC-SC20

WFC-SC30

WFC-SH10

WFC-SH20

WFC-SH30

A

93

98

98

B

63

75

88

C

63

75

88

D

63

75

88

Fig. 2 ACCESS CLEARANCES (IN.)

The roof on which equipment is to be

installed shall be capable of supporting the

operating weight of the absorption chiller,

associated pumps, cooling tower and piping.

Install the equipment on a well drained surface of

the roof at least 6 ft. from the edge. If the roof is

poorly drained at the equipment or in the

passageway to the equipment a suitable platform

of walkway should be provided adjacent to the

equipment and control panels so that it can be

serviced safely.

10

INSTALLATION