Page | 13

NETWORK CONFIGURATION

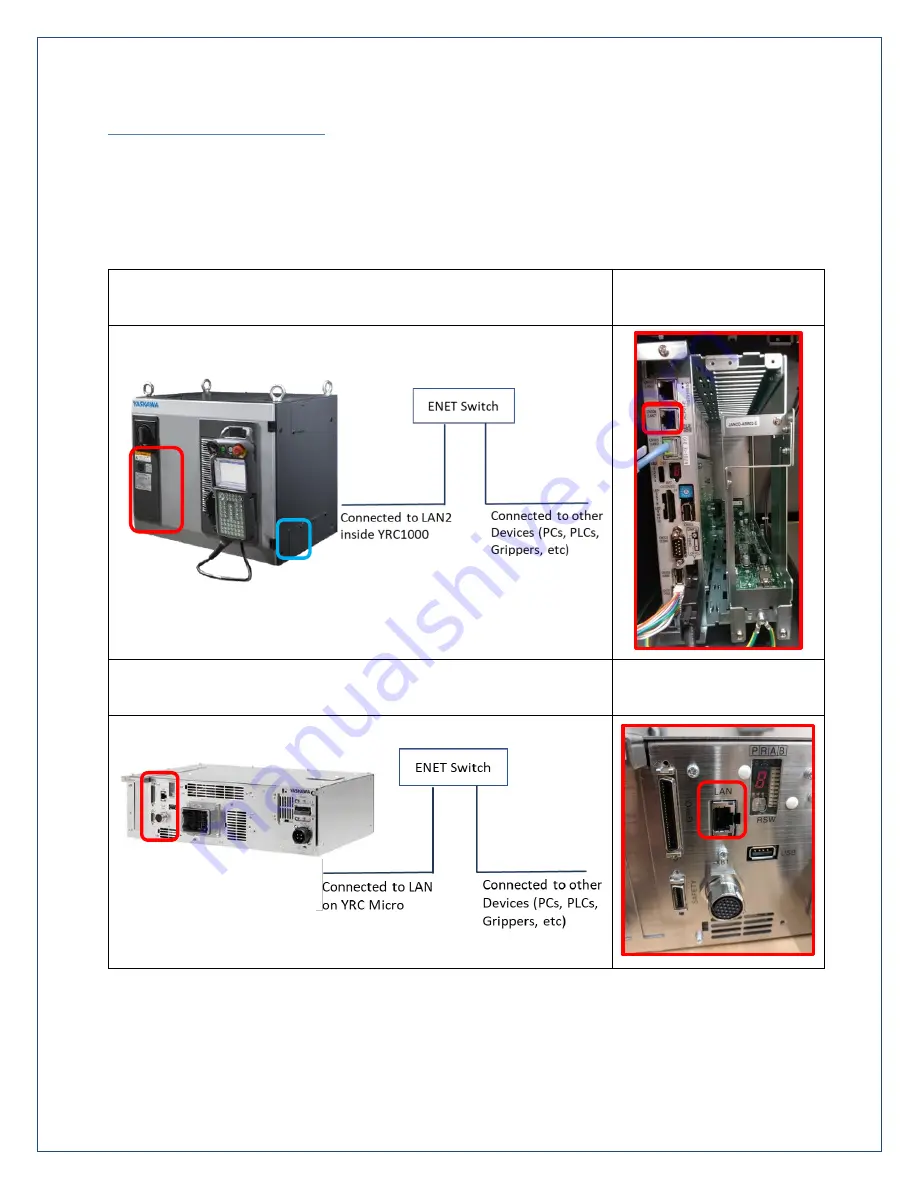

An Ethernet network will be used to establish communication between the SMART Series robot

controller and the Robotiq 2F gripper. Using the diagrams below, connect an Ethernet cable from the

networking port of the robot controller (LAN2 on YRC1000, LAN on YRC1000micro) to an installed

Ethernet switch.

Network Layout (YRC1000)

Controller Port

(YRC1000)

Network Layout (YRC1000micro)

Controller Port

(YRC1000micro)

Exit ports for cable(s)

network