2-10

183523-1CD

183523-1CD

2

Installation

2.3 Positioner Installation

RM2-755-RDR Postioner

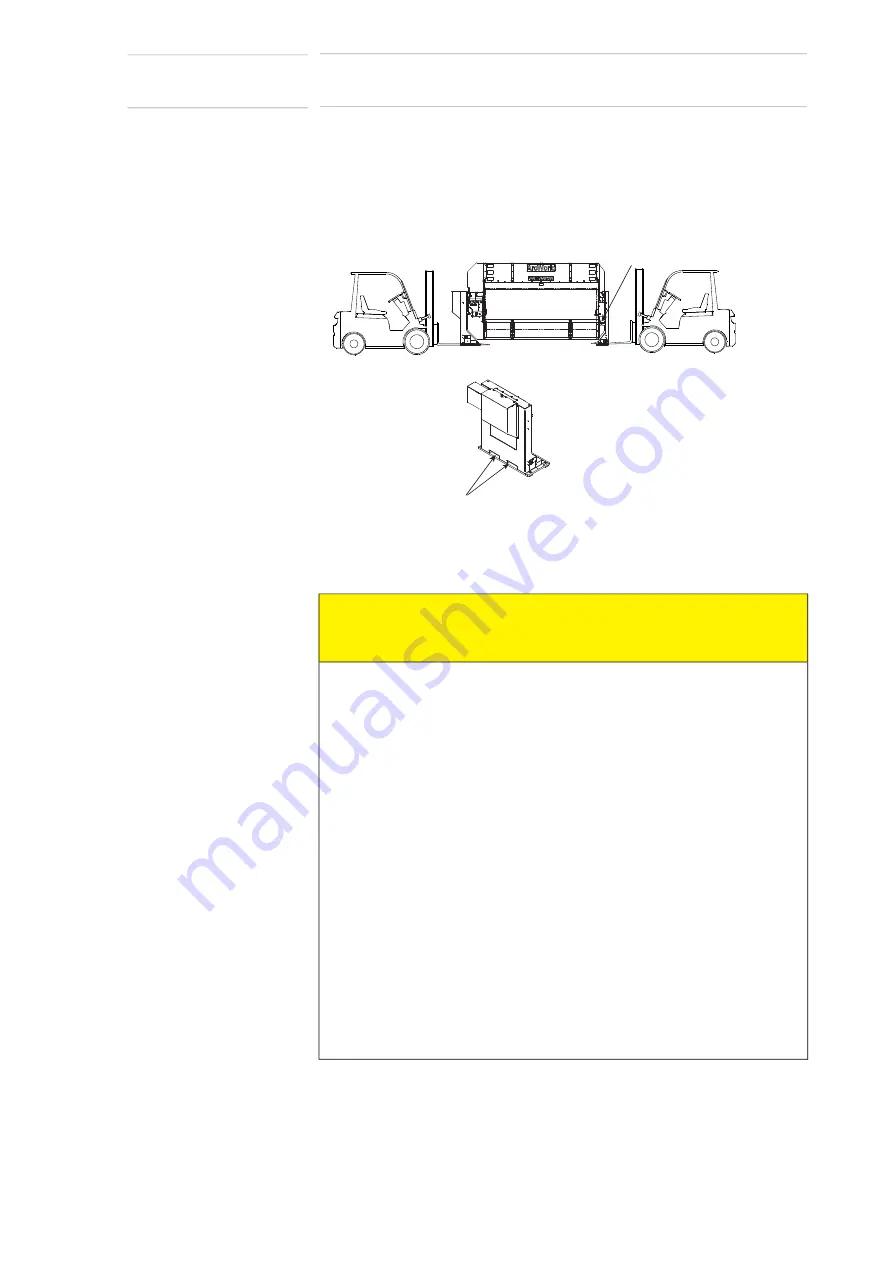

2.3.3.2 Using Forklifts

Two forklifts can be used with the forklift pockets when the Positioner is in

the shipping position and the shipping lifting bracket is installed (see

). Be sure that the Positioner is fixed with shipping bolts and

bracket before transposition, and lift in the posture as shown in

.

Fig. 2

-

5: Transporting the Positioner (Forklift)

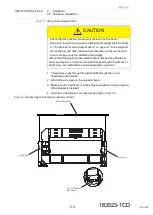

2.3.4 Mounting Positioner

The Positioner should be firmly mounted on a baseplate or foundation

strong enough to support the Positioner and withstand repulsion forces in

acceleration and deceleration.

Construct a solid foundation with the appropriate thickness to withstand

maximum repulsion forces of the Positioner.

SET-UP/SHIPPING

BRACKETS

FORKLIFT

POCKETS

CAUTION

• The floor should be strong enough to support the Positioner.

Construct a solid foundation with the appropriate thickness to

withstand maximum repulsion forces of the Positioner. Make sure

the thickness of the floor is 200mm or more because any

thickness less than 200mm is insufficient for mounting, even if the

floor is concrete. Before mounting the Positioner on the floor,

check the flatness, cracks, etc. of the floor and repair before

installing.

Shape of the Positioner may deform and its functional ability may be

compromised.

• Make sure the floor flatness and level complies with ASTM E1155

code minimum values of Ff of 20 and FI of 15.

If the flatness of the mounting face is insufficient, the shape of the

Positioner may deform and its functional ability may be compromised.

• Consult with a licensed civil engineer if the strength or integrity of

the floor is in question.

Not consulting a licensed civil engineer if there is any question

concerning the strength or integrity of the floor can cause equipment

damage.

30 of 104