6-6

166006-1CD

166006-1CD

6

Maintenance and Inspection

6.3 Grease Replenishment/Exchange for Speed Reducers

RM2-755/1255SL

Positioner

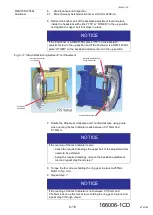

6.3.1.2 Slewing Bearing Raceway

1. Remove the Headstock upper column cover.

2. Locate the grease fitting shown in Fig and grease

with Yaskawa

P/N 132177-1, Gadus S2 V220 2

Fig. 6

-

4: Slewing Bearing Raceway Grease Fittings

6.3.1.3 Gear and Pinion Teeth Lubrication

There are two primary methods of lubricating the Gear and Pinion Teeth.

The two ways are either using grease fittings or using a Multiport

Lubricator system.

Grease Fittings

If the Positioner is retrofitted with the optional remote main axis kit, the

lubrication process will vary from standard method. For convenience, the

main axis lubrication grease fittings are moved from the main axis motor

cover to the top of the headstock column as shown below which allows

main axis lubrication while running. Pump grease into each fitting as the

Positioner turns clockwise or counterclockwise as indicated in the label.

Fig. 6

-

5: Optional Remote Main Axis Kit Lubrication Fittings

SLEWING BEARING

RACEWAY GREASE

FITTINGS

57 of 145