problems are detected.

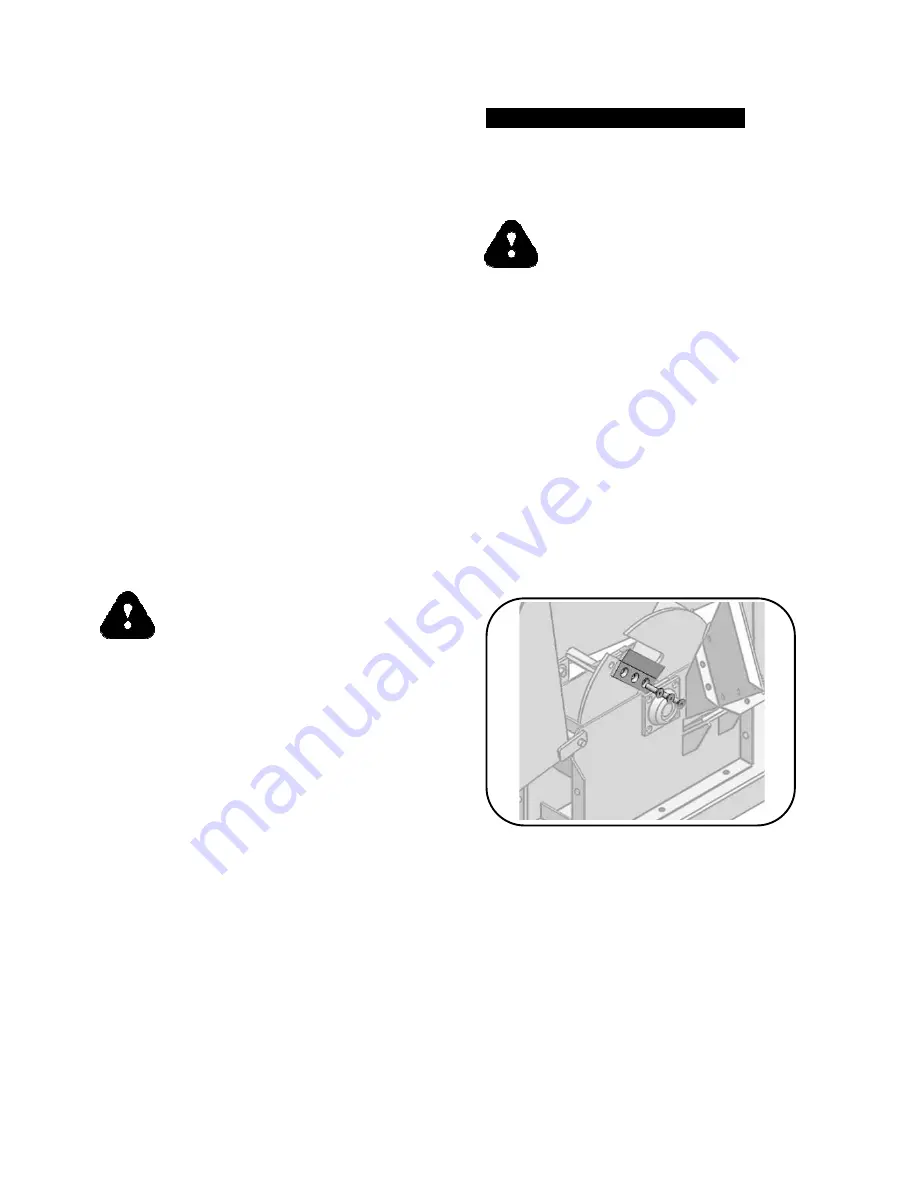

Replacing Power Belt

1.Stop the engine, disconnect the spark

plug and check that the engine has

stopped completely.

2.Remove the bolts holding the belt guard

and remove.

3.Loosen the bolts holding the engine at its

base.

4.Adjust belt tension by loosening the

tensioner bolt, use a 1/2 " hex wrench.

5.Proceed to replace and adjust tension

again until it is felt tight by pressing down

with the finger.

6.Assemble the belt guard in the same way

it was disassembled.

Cleaning of the equipment

Carefully clean the cutting chamber after

each use.

WARNING

The rotor blade is sharp. Wear

leather gloves to protect your

hands when cleaning the cutting

chamber.

NOTE:

Blasting pressurized water

chamber is not recommended.

Taking care of your engine

NOTE:

Review the sections of maintenance

and operation of the engine manual for

detailed instructions.

1. Check the oil level.

2. Clean the engine regularly with a

cloth or brush. Keep clean the air

intake system to allow proper air

circulation. Remove all grass, dirt

and combustible debris from muffler

area.

sconnect the spark

plug and check that the engine has

2.Remove the bolts holding the belt guard

3.Loosen the bolts holding the engine at its

4.Adjust belt tension by loosening the

" hex wrench.

5.Proceed to replace and adjust tension

again until it is felt tight by pressing down

the belt guard in the same way

Cleaning of the equipment

ting chamber after

Wear

leather gloves to protect your

hands when cleaning the cutting

Blasting pressurized water into the

Taking care of your engine

ns of maintenance

and operation of the engine manual for

2. Clean the engine regularly with a

cloth or brush. Keep clean the air

intake system to allow proper air

circulation. Remove all grass, dirt

and combustible debris from muffler

SERVICING YOUR WOODCHIPPER

Rotor Blade

WARNING

The rotor blade is sharp.

leather gloves to protect your

hands when the cleaning cutting

chamber.

Blade re-sharpening

1. Stop the engine, disconnect

plug and check that the rotor of the chipper

has stopped completely.

2. Open chipper by loosening the lock knob.

3. Remove the bolts securing the blade to

the rotor using a 5mm Allen key and a 9/16”

hex wrench on the opposite

4. Remove the blade and proceed

change or resharpen blade

5. Blade must be sharped at a 30deg. angle

and must not overheat to loose its heat

treatment properties.

6. Tighten the bolts again.

NOTE:

To remove the bolts from the blade

is recommended to place a piece of wood

in between the rotor and the outside edge

to lock it, preventing it from rotating when

loosening the bolts.

Anvil sharpening or adjustment

1. Loosen the bolts from under the anvil

bed. Use a 9/16 "Hex Wrench and

5mm Allen key.

2. Between the blade and the anvil,

15

YOUR WOODCHIPPER

The rotor blade is sharp. Wear

leather gloves to protect your

hands when the cleaning cutting

1. Stop the engine, disconnect the spark

plug and check that the rotor of the chipper

loosening the lock knob.

3. Remove the bolts securing the blade to

the rotor using a 5mm Allen key and a 9/16”

e side.

4. Remove the blade and proceed to

blade.

5. Blade must be sharped at a 30deg. angle

and must not overheat to loose its heat

bolts from the blade, it

nded to place a piece of wood

in between the rotor and the outside edge

it from rotating when

Anvil sharpening or adjustment

1. Loosen the bolts from under the anvil

bed. Use a 9/16 "Hex Wrench and

2. Between the blade and the anvil,

Содержание YB3514

Страница 25: ...25 NOTES...