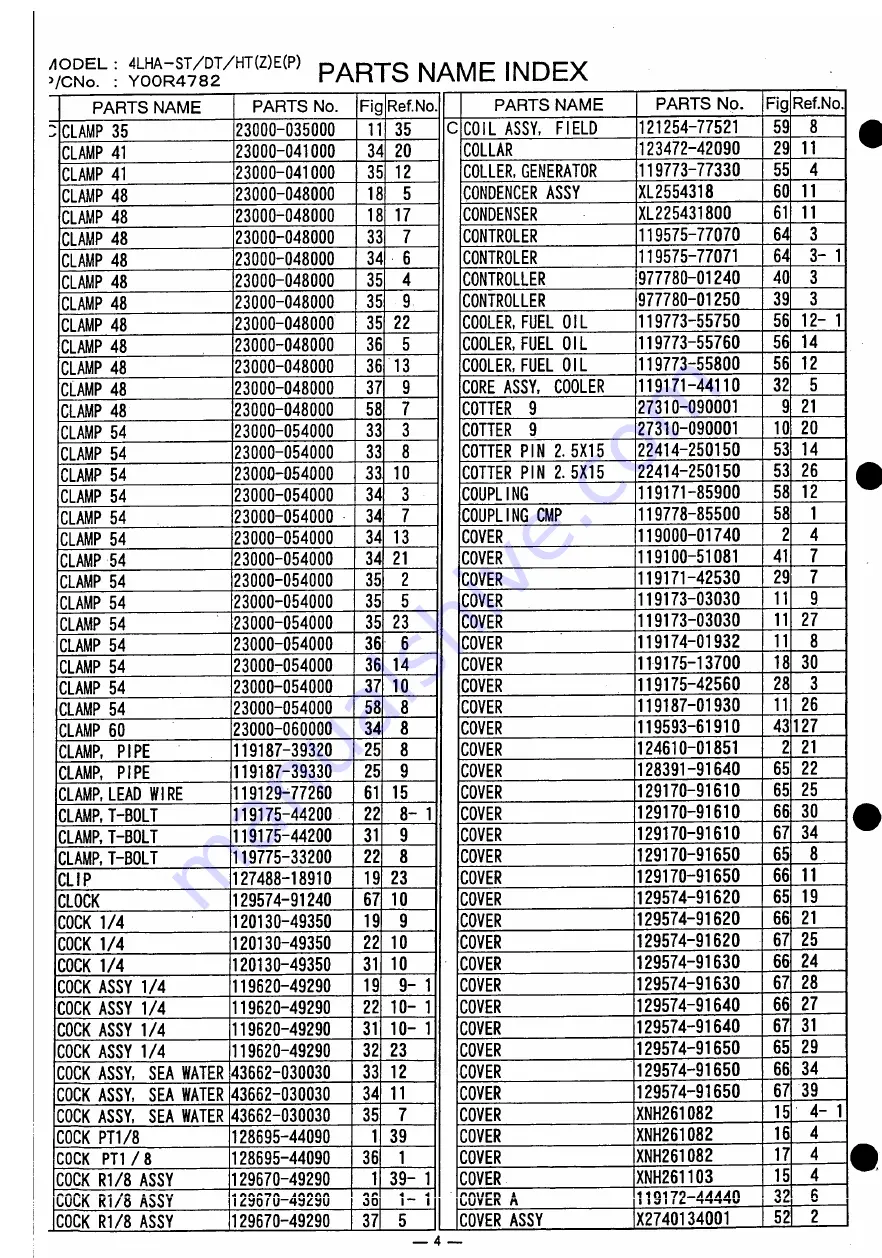

PARTS NAME

PARTS No. Fig Ref.No.

PARTS NAME

PARTS No. Fig Ref.No.

: CLAMP 35

23000-035000

11 35

C COIL ASSY, FIELD

121254-77521

59 8

CLAMP 41

23000-041000

34 20

C

COLLAR

123472-42090

29 11

CLAMP 41

23000-041000

35 12

C

COLLER, GENERATOR

119773-77330

55 4

CLAMP 48

23000-048000

18 5

C

CONDENCER ASSY

XL2554318

60 11

CLAMP 48

23000-048000

18 17

C

CONDENSER

XL225431800

61 11

CLAMP 48

23000-048000

33 7

C

CONTROLER

119575-77070

64 3

CLAMP 48

23000-048000

34 6

C

CONTROLER

119575-77071

64 3- 1

CLAMP 48

23000-048000

35 4

C

CONTROLLER

977780-01240

40 3

CLAMP 48

23000-048000

35 9

C

CONTROLLER

977780-01250

39 3

CLAMP 48

23000-048000

35 22

C

COOLER, FUEL OIL

119773-55750

56 12- 1

CLAMP 48

23000-048000

36 5

C

COOLER, FUEL OIL

119773-55760

56 14

CLAMP 48

23000-048000

36 13

C

COOLER, FUEL OIL

119773-55800

56 12

CLAMP 48

23000-048000

37 9

C

CORE ASSY, COOLER

119171-44110

32 5

CLAMP 48

23000-048000

58 7

C

COTTER 9

27310-090001

9 21

CLAMP 54

23000-054000

33 3

C

COTTER 9

27310-090001

10 20

CLAMP 54

23000-054000

33 8

C

COTTER PIN 2.5X15

22414-250150

53 14

CLAMP 54

23000-054000

33 10

C

COTTER PIN 2.5X15

22414-250150

53 26

CLAMP 54

23000-054000

34 3

C

COUPLING

119171-85900

58 12

CLAMP 54

23000-054000

34 7

C

COUPLING CMP

119778-85500

58 1

CLAMP 54

23000-054000

34 13

C

COVER

119000-01740

2 4

CLAMP 54

23000-054000

34 21

C

COVER

119100-51081

41 7

CLAMP 54

23000-054000

35 2

C

COVER

119171-42530

29 7

CLAMP 54

23000-054000

35 5

C

COVER

119173-03030

11 9

CLAMP 54

23000-054000

35 23

C

COVER

119173-03030

11 27

CLAMP 54

23000-054000

36 6

C

COVER

119174-01932

11 8

CLAMP 54

23000-054000

36 14

C

COVER

119175-13700

18 30

CLAMP 54

23000-054000

37 10

C

COVER

119175-42560

28 3

CLAMP 54

23000-054000

58 8

C

COVER

119187-01930

11 26

CLAMP 60

23000-060000

34 8

C

COVER

119593-61910

43 127

CLAMP, PIPE

119187-39320

25 8

C

COVER

124610-01851

2 21

CLAMP, PIPE

119187-39330

25 9

C

COVER

128391-91640

65 22

CLAMP.LEAD WIRE

119129-77260

61 15

C

COVER

129170-91610

65 25

CLAMP, T-BOLT

119175-44200

22 8- 1

C

COVER

129170-91610

66 30

CLAMP. T-BOLT

119175-44200

31 9

C

COVER

129170-91610

67 34

CLAMP, T-BOLT

119775-33200

22 8

C

COVER

129170-91650

65 8

CLIP

127488-18910

19 23

C

COVER

129170-91650

66 11

CLOCK

129574-91240

67 10

C

COVER

129574-91620

65 19

COCK 1/4

120130-49350

19 9

C

COVER

129574-91620

66 21

COCK 1/4

120130-49350

22 10

C

COVER

129574-91620

67 25

COCK 1/4

120130-49350

31 10

C

COVER

129574-91630

66 24

COCK ASSY 1/4

119620-49290

19 9- 1

C

COVER

129574-91630

67 28

COCK ASSY 1/4

119620-49290

22 10- 1

C

COVER

129574-91640

66 27

COCK ASSY 1/4

119620-49290

31 10- 1

C

COVER

129574-91640

67 31

COCK ASSY 1/4

119620-49290

32 23

C

COVER

129574-91650

65 29

COCK ASSY, SEA WATER

43662-030030

33 12

C

COVER

129574-91650

66 34

COCK ASSY, SEAWATER 43662-030030

34 11

C

COVER

129574-91650

67 39

COCK ASSY, SEA WATER

43662-030030

35 7

C

COVER

XNH261082

15 4- 1

COCK PT1/8

128695-44090

1 39

C

COVER

XNH261082

16 4

COCK PTI / 8

128695-44090

36 1

C

COVER

XNH261082

17 4

COCK RI/8 ASSY

129670-49290

1 39- 1

C

COVER

XNH261103

15 4

COCK RI/8 ASSY

* r» r» f» -r />

J

n n rv rt

i r»

J D

1 " 1

C

COVER A

i i n i T O — d / M j i n

1 1 J 1 1 L. f t - t - T U

32 5

COCK RI/8 ASSY

129670-49290

37 5

C

COVER ASSY

X2740134001

52 2

— 4 —

Содержание 4LHA-HTP

Страница 77: ...Y00R4782 1 Vy97Qy Fig I CYLINDER BLOCK 1 i n c 1 3 1 FLYWHEEL SIDE 1 1 1 55 55 58 46 FUEL INJECTION P U M P 20...

Страница 79: ...Y00R4782 2 Fig fc GEAR HOUSING REFER TO F i g l REFER TO F i g 2 8 2 9 7 EFER TO Fi g 5...

Страница 81: ...Y00R4782 FLYWHEEL HOUSING 4LHA STZE P 4LHA DTZE P 4LHA HTZE P 13 1 4...

Страница 87: ...Y00R4782 LUB OIL S U M P 9 7 7 7 7 o 1 01 21 2 N 4LHA HTE P 4LHA HTZE P OPTIONAL 12...

Страница 89: ...Y0OR4782 OIL SEAL HOUSING REFER TO Fig 1...

Страница 101: ...Y00R4782 Fig j 2 R V Tfc JI K S U C T I O N M A N I F O L D...

Страница 107: ...Y00R4782 Fig CAMSHAFT DRIVING GEAR...

Страница 109: ...Y00R4782 Fig 1 C e 4LHA ST Z E P I O TURBOCHARGER 4LHA ST Z E P REFER TO F i g 1 3...

Страница 111: ...Y00R4782 r 1 ft t y 4LHA DT Z E P F i g l O TURBOCHARGER 4LHA DT Z E P REFER TO F i g 1 3...

Страница 113: ...Y00R4782 1 7 fcf 4LHA HT Z E P Fig I I T U R B O C H A R G E R 4LHA HT Z E P...

Страница 115: ...Y00R4782 Fig 18 ftiB M I X I N G E L B O W E X H A U S T B E N D 5...

Страница 117: ...Y00R4782 Fig 18 1 5 E W K M I X I N G E L B O W E X H A U S T B E N D 5...

Страница 121: ...Y00R4782 Fig I W AIR COOLER 4 L H A H T E P 4 L H A H T Z E P REFER TO F i g 24...

Страница 127: ...Y00R4782 F i g t C LUB OIL COOLER REFER TO F i g 1 9 FLYWHEEL SIDE...

Страница 131: ...Y00R4782 Fig 24 LUB OIL SYSTEM REFER TO Fi g 2 4LHA STZE P 4LHA DTZE P REFER TO Fi g 6...

Страница 135: ...Y00R4782 Fig C O LUB OIL PIPE TURBOCHARGER REFER TO F i g 1 5 1 6 1 7...

Страница 137: ...Y00R4782 Fig 27 MMM V LUB OIL PIPE COOLER REFER TO F i g 22 a 7 f O U T L O STRAINER OUT...

Страница 139: ...Y00R4782 Q Q m y7 m 4LHA ST DT Z E P Fi g O C S W P U M P 4LHA ST DT Z E P...

Страница 141: ...Y00R4782 OQ ymxy 4LHA HT Z E P Fi g fc 57 C S W P U M P 4LHA HT Z E P...

Страница 143: ...Y00R4782 Fig COOLING FRESH W A T E R P U M P REFER TO F i g 62...

Страница 145: ...Y00R4782 Fig 31 mo z 4LHA ST DT Z E P C F W COOLER 4LHA ST DT Z E P 5 f fc f ui FLYWHEEL SIDE...

Страница 147: ...Y00R4782 Fig Q O mo z 4LHA HT Z E P O C F W COOLER 4LHA HT Z E P FITTING TO SHIP BODY REFER TO F i g 1 0...

Страница 149: ...Y00R4782 Q Q mMW 4LHA STE DTE P Fi g O O C S W PIPE 4LHA STE DTE P REFER TO F i g 3 1...

Страница 151: ...Y00R4782 n O A nm uy ss 4LHA STZE DTZE CP F i g Q H C S W PIPE 4LHA STZE DTZE P PS COOLER REFER TO F i g 31 PACKGED PART...

Страница 153: ...Y00R4782 Fig O A fimiU7 m 4LHA STZE DTZE P O H C S W PIPE 4LHA STZE DTZE P REFER TO F i g 3 1 PACKGED PART...

Страница 155: ...Y00R4782 g g nm uy m 4LHA HT Z E P C S W PIPE 4LHA HT Z E P REFER TO F i g 32 11 12 SIED PART...

Страница 157: ...Y00R4782 Fig o e nmiuy 4LHA ST DT Z E P O D C F W PI PE 4LHA ST DT Z E P...

Страница 159: ...Y00R4782 Fig Q 7 JMP W7 I 4LHA HT Z E P O f C F W PIPE 4LHA HT Z E P REFER TO F i g 2 3...

Страница 161: ...Y00R4782 Fi g Q O C S W STRAINER OPTIONAL c s w PUMP KINGSTON C O C K...

Страница 163: ...Y00R4782 QQ k Wy7 STD 17i 3 Fig WCJ BILGE P U M P STD OPTIONAL E A S S Y MOTOR ASSY utap OUT LET...

Страница 165: ...Y00R4782 Fig An MVftyy DX tJz zy H U BILGE PUMP DX OPTIONAL t A S S Y MOTOR ASSY IlfcUiP OUT LET...

Страница 167: ...Y00R4782 4 1 mmxyy 4LHA ST DT Z E P I FUEL INJECTION P U M P 4LHA ST DT Z E P...

Страница 169: ...Y00R4782 mmxyy 4LHA ST DT Z E P Fifl I F U E L I N J E C T I O N P U M P 4 L H A S T D T Z E P...

Страница 171: ...Y00R4782 Fifl 42 m y 4LHA HT Z E P FUEL INJECTION PUMP 4LHA HT Z E P REFER TO F i g 5 4 iREFER TO F i g 5...

Страница 173: ...Y00R4782...

Страница 175: ...Y00R4782...

Страница 177: ...Y00R4782 43 M t GOVERNOR...

Страница 179: ...Y00R4782 A JWD f Ktfxr Fig F U E L F E E D P U M P REFER TO Fig 41...

Страница 187: ...Y00R4782 Fig A O r W7 4LHA ST DT Z E P H O FUEL PIPE 4LHA ST DT Z E P...

Страница 189: ...Y00R4782 Fig A Q miUy 4LHA ST DT Z E P f O FUEL PI PE 4LHA ST DT Z E P...

Страница 191: ...Y00R4782 Fig A Q miU7 4LHA HT Z E P t O FUEL PIPE 4LHA HT Z E P REFER TO F i g 51 REFER TO F i g 4 2...

Страница 193: ...Y00R4782 Fig C n B7 f 4LHA ST DT Z E P U U FUEL STRAINER 4LHA ST DT Z E P...

Страница 195: ...Y00R4782 Fig K 1 TO7 i 4LHA HT Z E P w I FUEL STRAINER 4LHA HT Z E P REFER TO F i g 12...

Страница 197: ...Y00R4782 Fig 52 OIL WATER SEPARATER OPTIONAL 19 mv t 9 14 F R O M FUEL TANK...

Страница 201: ...Y00R4782 K A mWtm 4LHA HT Z E P F i g O H ENGINE STOP DEVICE 4LHA HT Z E P REFER TO F i g 4 2 V 16 OPTIONAL...

Страница 203: ...Y00R4782 F i g O O P O W E R STEERING P U M P C F W P U M P...

Страница 205: ...Y00R4782 Fig UU P O W E R S T E E R I N G C O O L E R T A N K 1 6...

Страница 207: ...Y00R4782 57 ATFA f Fig O I ATF PIPE REFER TO F i g 5 6 FER TO F i g 5 5...

Страница 211: ...Y00R4782 Fifl W O STARTING MOTOR REFER TO F i g 3...

Страница 213: ...Y00R4782 GENERATOR REFER TO Fig 2...

Страница 215: ...Y00R4782 Fig D I GENERATOR OPTIONAL REFER TO F i g 30 REFER TO F i g 60...

Страница 221: ...Y00R4782 Fl g O O SENSOR MOUNT...

Страница 223: ...Y00R4782 H E A T E R P L U G O P T I O N A L 4 L H A H T E P 4 L H A H T Z E P...

Страница 225: ...Y00R4782 Fig OO I N S T R U M E N T P A N E L B T Y P E O P T I O N A L...

Страница 227: ...Y00R4782 Fig NSTRUMENT PANEL C TYPE OPTIONAL...

Страница 229: ...Y00R4782 66 Fig OO I N S T R U M E N T P A N E L C T Y P E O P T I O N A L...

Страница 231: ...Y00R4782 Fig 67 4 0 INSTRUMENT PANEL D TYPE OPTIONAL...

Страница 233: ...Y00R4782 Fig 67 N S T R U M E N T P A N E L D T Y P E O P T I O N A L...

Страница 235: ...Y00R4782 Fig 6 8 T O O L...

Страница 237: ...Y00R4782 Fig D GASKET SET OPTIONAL 1 A...

Страница 302: ...Example of setup with HSW630A1 Hurth marine gear WATER INLET IS M l o 3 0 WATER INLET 2 3...

Страница 303: ...Chapter 1 General 5 Dimensions i4LHA Series 4LHA STZE STZP 9 96 XVW 9 06 um 1 18...

Страница 305: ...Chapter 1 General 5 Dimensions 4LHA Series 4LHA DTZE DTZP 9 96 XVW g oe nm 1 20...

Страница 306: ...Example Of setup with K M 5 A CKM5A is not applicable for 4LHA HTP HSW450A2 only i 13 oi o S R S 36B 6 350 5...

Страница 307: ...Chapter 1 General 5 Dimensions i4LHA Series 4LHA HTZE HTZP g 96 xvw S06NIW 1 22...

Страница 317: ...Chapter 1 General 7 Electrical Diagrams m4LHA Series 4LHA STZE 1 30...

Страница 318: ...Chapter 1 General 7 Electrical Diagrams 4LHA Series 4LHA DTZE 1 32...

Страница 319: ...Chapter 1 General 7 Electrical Diagrams 4LHA Series 4LHA HTE HTZE Eng stop solenoid 1 33...

Страница 356: ...Chapter 2 Basic Engine 10 Flywheel t4LHA Series 10 Flywheel 10 1 Dimensions of flywheel and flywheel housing 2 36...

Страница 358: ...Chapter 3 Fuel Injection Equipment 1 Fuel Supply System 1 Fuel Supply System Fuel injection pump 3 1 1...

Страница 473: ...Chapter 3 Fuel Injection Equipment 9 Tools 4LHA Serie t 3 2 51...

Страница 483: ...Chapter 4 Intake and Exhaust System 4 Turbocharger 4LHA Series 4 2 Components RHC61W Turbocharger 4 6...

Страница 507: ...Chapter 5 Lubrication System 1 Lubrication System 4LHA Serie 1 1 Construction...

Страница 519: ...Chapter 6 Cooling Water System 1 Cooling Water System 4LHA Series Cylinder block...

Страница 520: ...Chapter 6 Cooling Water System 1 Cooling Water System t4LHA Sen 1 2 Sea water line Heat exchanger 6 3...