ENGINE

6-26

3TNV88F Service Manual

Cylinder Head

Reassembly of Cylinder Head

Use new gaskets, O-rings and seals for the

reassembly of the cylinder head.

NOTICE

Liberally oil all components during reassembly to

prevent premature wear or damage.

■

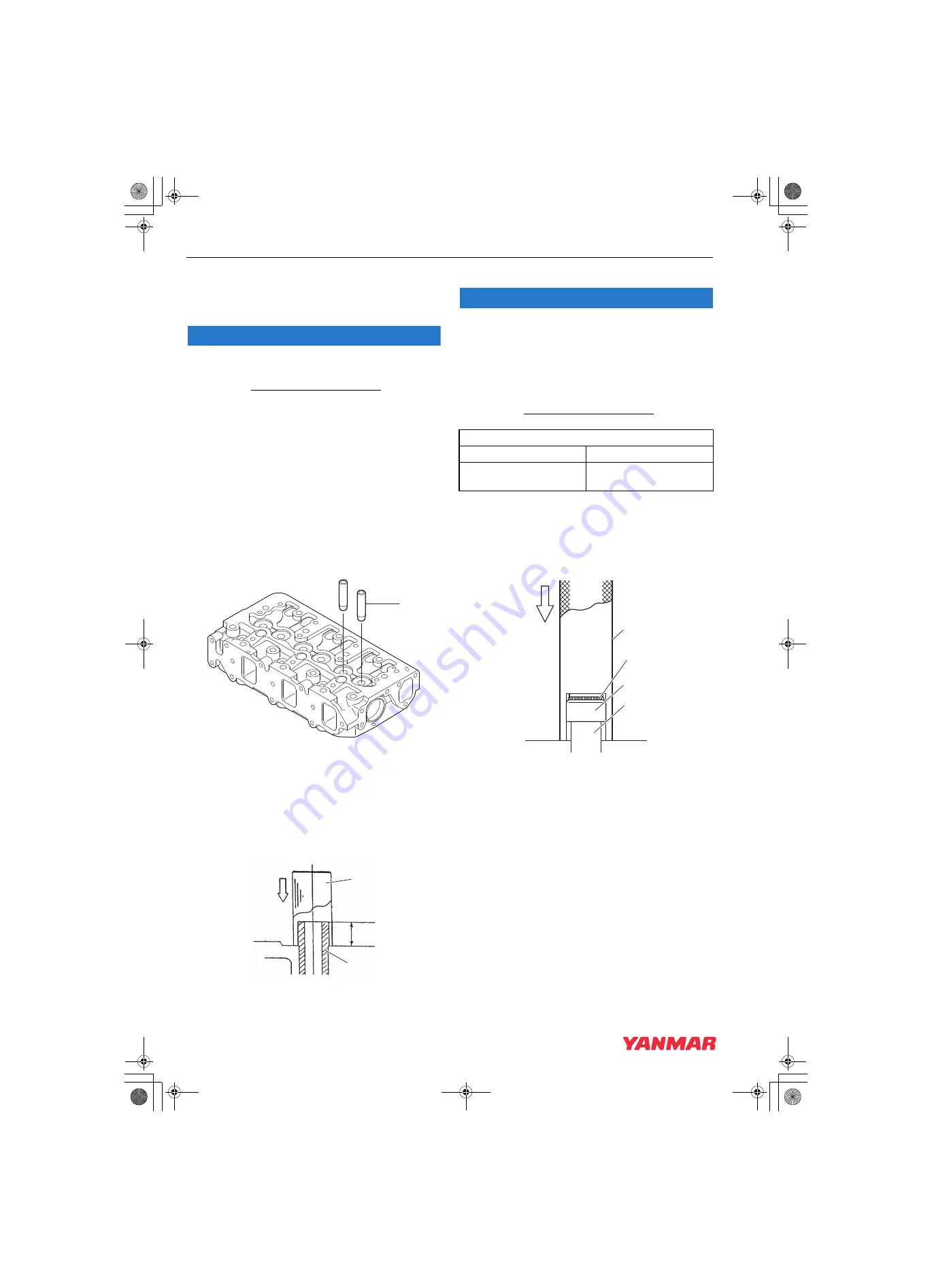

Reassembly of valve guides

1. The valve guides are installed into the cylinder

head with an extremely tight press fit. Before

installing the valve guides, place the valve

guides in a freezer for at least twenty minutes

This will cause the valve guides to contract,

making it easier to install the valve guides into

place.

2. Immediately after removing the valve guides

from the freezer, insert the valve guides

in their proper positions.

Figure 6-27

3. Finish installing the valve guides

into the cylinder head to the

proper height

using the valve

guide installation tool

(Figure 6-28, (2))

.

See

Valve Guide Projection specification starting on

page 6-4.

Figure 6-28

■

Reassembly of intake and exhaust valves

NOTICE

Always install new valve stem seals.

The exhaust valve stem seals are different than the

intake valve stem seals and can be identified by

either the paint marks on the outside of the seals or

by the color of the seal spring

.

Ensure they are installed in the correct locations.

1. Oil the lip of the valve stem seal

(Figure 6-29, (2)).

Using the valve stem seal

installation tool

, install a new

valve stem seal on each of the valve guides

(Figure 6-29, (3))

.

Figure 6-29

2. Measure the distance

(Figure 6-30, (1))

from

the cylinder head to valve stem seal to ensure

proper clearance

(Figure 6-30, (2))

between

the guide and the seal.

See Valve Stem Seal

Projection specification on page 6-5.

1

046619-00X00

K0001756A

3

2

1

Marking

Intake

Exhaust

None

Yellow

(Paint on outside of seal)

3

2

4

1

K0001873B

3TNV88F_SVM_A4.book 26 ページ 2012年7月26日 木曜日 午後6時4分