ENGINE

3TNV88F Service Manual

6-25

Cylinder Head

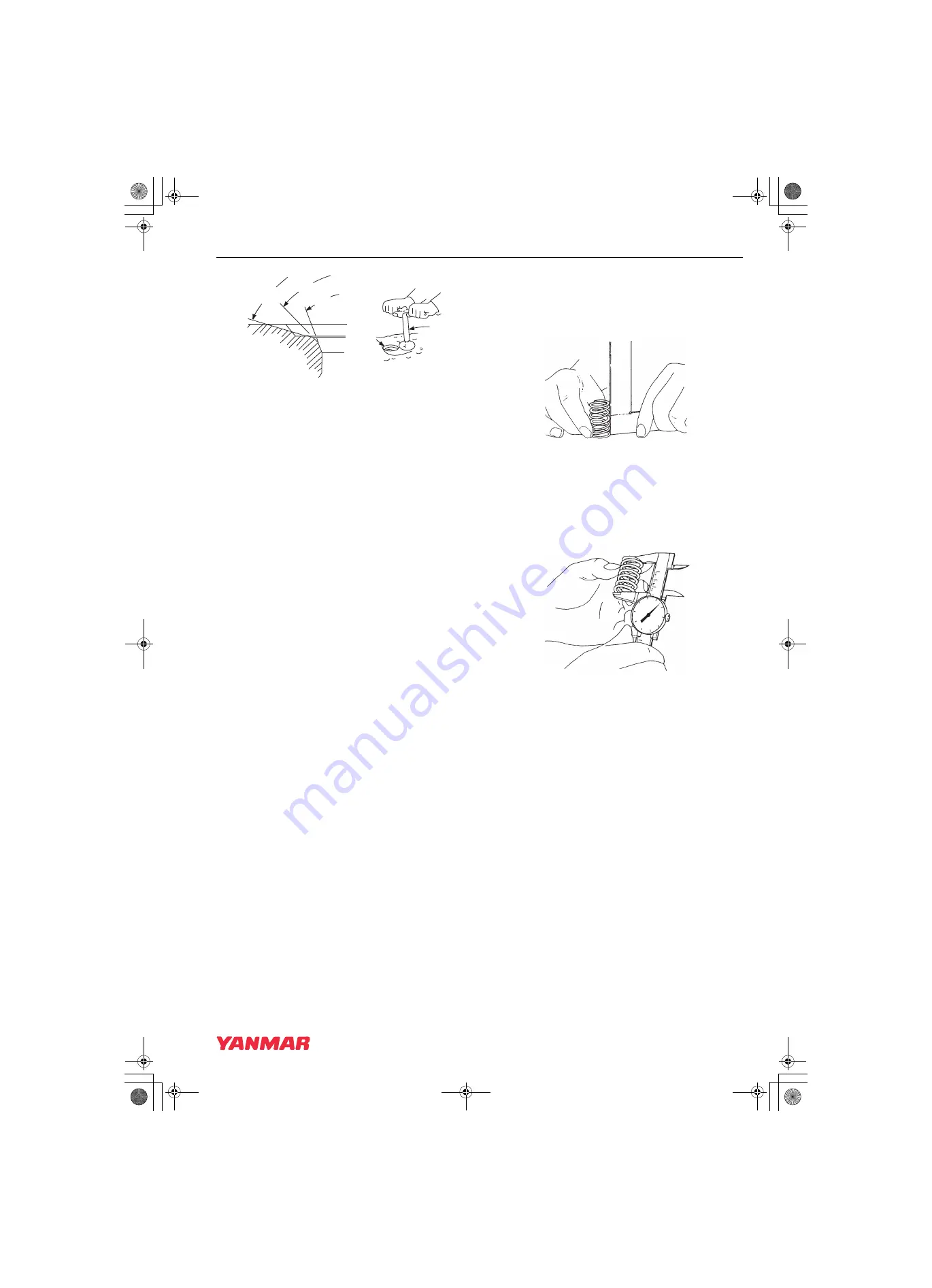

Figure 6-24

The valve seat diameter can be adjusted by top-

grinding with a 150° stone to make the seat

diameter smaller, and bottom-grinding using a 40°

stone to make the seat diameter larger. Once the

seat location has been corrected, grind and lap the

seat angle

(Figure 6-24, (1))

to specification.

Cylinder Head on page 6-4 for specifications

.

Grind the valve face and/or valve seat only enough

to return them to serviceable condition. Grinding is

needed if the valve and the valve seat do not

contact correctly. Check the recession after

grinding.

If the valve or seat require grinding, lap the valve

after grinding. Lap the valve face to the valve seat

using a mixture of valve lapping compound and

engine oil.

Be sure to thoroughly wash all parts to remove all

grinding powder or compound.

■

Inspection of valve springs

Inspect the valve springs. If damage or corrosion is

seen, or if measurements exceed the specified

limits, replace the springs.

Fractures

Check for fractures on the inside and outside

portions of the springs. If the valve spring is

fractured, replace the valve spring.

Corrosion

Check for corrosion of the spring material caused

by oxidation.

Squareness

Use a flat surface and a square to check each

spring for squareness

Spring on page 6-5 for the service limit.

Figure 6-25

Free length

Use a caliper to measure the length of the spring

See Valve Spring on page 6-5 for

the service limit.

Figure 6-26

K0001862

1

40°

150°

2

3

K0000201

0

1

2

3

4

5

6

7

9

8

K0000200

3TNV88F_SVM_A4.book 25 ページ 2012年7月26日 木曜日 午後6時4分