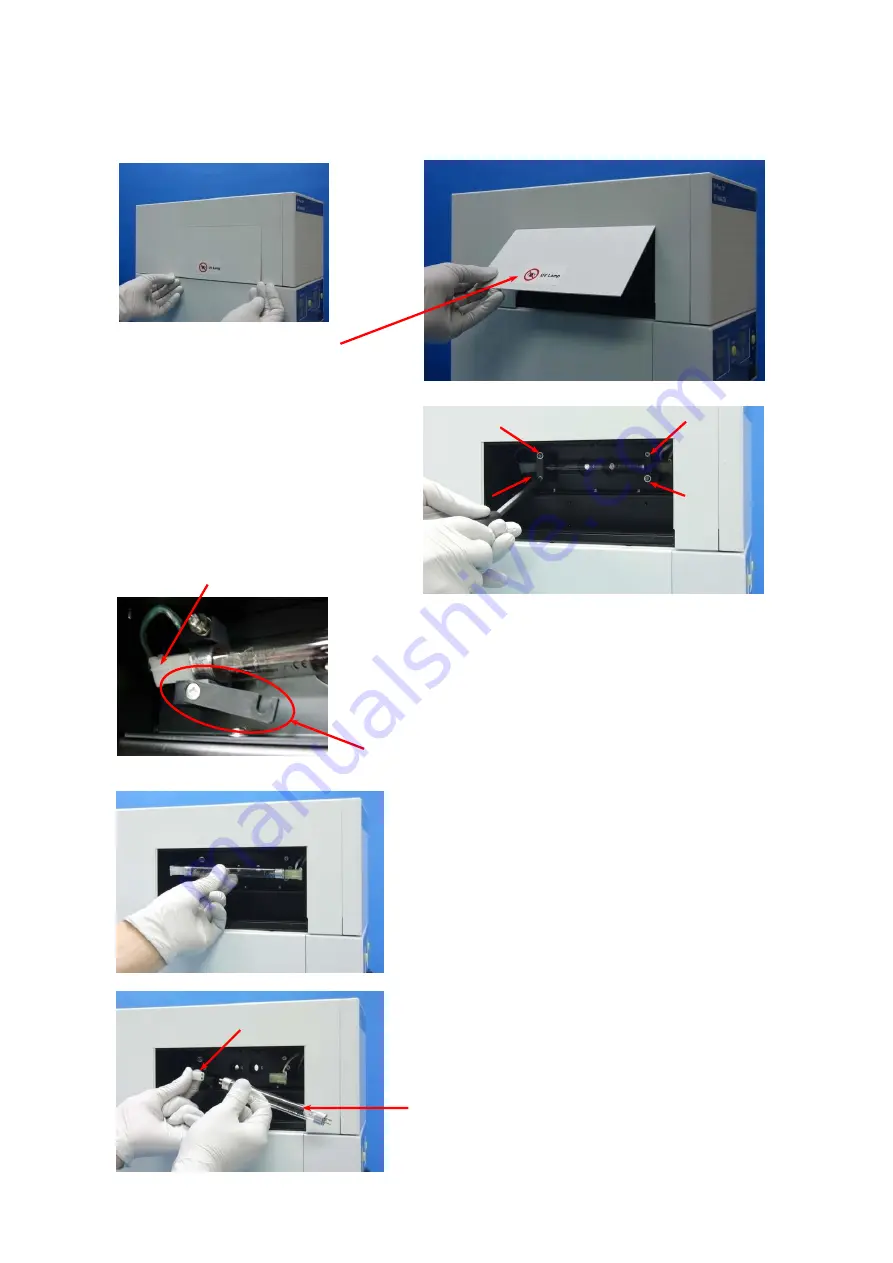

How to Replace the UV Lamp (A390)

Remove the cover (magnet)

as shown in the photo.

Install a new UV lamp.

Loosen 4 screws, and trip the fixing bracket.

Remove the connectors at both ends of

the UV lamp, and take out the UV lamp.

Connector

A New UV lamp

Fixing bracket

Connector

- 2 -