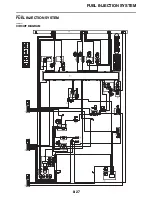

FUEL INJECTION SYSTEM

8-33

EAM30286

TROUBLESHOOTING DETAILS (FAULT CODE)

This section describes the measures per fault code number displayed on the Yamaha diagnostic tool.

Check and service the items or components that are the probable cause of the malfunction following

the order given.

After the check and service of the malfunctioning part have been completed, delete the fault codes dis-

played on the Yamaha diagnostic tool according to the reinstatement method.

Fault code No.:

Fault code number displayed on the Yamaha diagnostic tool when the engine failed to work normally.

Diagnostic code No.:

Diagnostic code number to be used when the diagnostic mode is operated. Refer to “DIAGNOSTIC

CODE: SENSOR OPERATION TABLE” on page 9-12.

Parts connected to the ECU

The following parts are connected to the ECU.

When checking for a power short circuit, the couplers must be disconnected from all of the following

parts beforehand.

Fault code No. 12

•

Crankshaft position sensor

•

Intake air pressure sensor

•

Fuel injector

•

Coolant temperature sensor

•

Ignition coil

•

Intake air temperature sensor

•

Throttle position sensor

Fault code No.

12

Item

Crankshaft position sensor: no normal signals are received from

the crankshaft position sensor.

Fail-safe system

Unable to start engine

Unable to drive vehicle

Diagnostic code No.

—

Diagnostic tool display

—

Procedure

—

Item

Probable cause of malfunc-

tion and check

Maintenance job

Confirmation of service com-

pletion

1

Connection of crankshaft posi-

tion sensor coupler.

Check the locking condition of

the coupler.

Disconnect the coupler, and

check the pins (for bent or bro-

ken terminals and locking condi-

tion of the pins).

Improperly connected

Con-

nect the coupler securely, or

repair/replace the wire harness.

Crank the engine, and then

check the condition of the fault

code using the malfunction

mode of the Yamaha diagnostic

tool.

Condition is “Recovered”

Go

to item 7 and finish the service.

Condition is “Detected”

Go to

item 2.

2

Connection of wire harness

ECU coupler.

Check the locking condition of

the coupler.

Disconnect the coupler, and

check the pins (for bent or bro-

ken terminals and locking condi-

tion of the pins).

Improperly connected

Con-

nect the coupler securely, or

repair/replace the wire harness.

Crank the engine, and then

check the condition of the fault

code using the malfunction

mode of the Yamaha diagnostic

tool.

Condition is “Recovered”

Go

to item 7 and finish the service.

Condition is “Detected”

Go to

item 3.

Содержание WR250F 2022

Страница 5: ...EAM20093 YAMAHA MOTOR CORPORATION U S A WR MOTORCYCLE LIMITED WARRANTY...

Страница 8: ......

Страница 10: ......

Страница 41: ...MULTI FUNCTION DISPLAY 1 29...

Страница 62: ...ELECTRICAL SPECIFICATIONS 2 9 Radiator fan motor fuse 5 0 A Spare fuse 15 0 A...

Страница 70: ...CABLE ROUTING DIAGRAM 2 17 EAM20152 CABLE ROUTING DIAGRAM Frame and engine left side view...

Страница 72: ...CABLE ROUTING DIAGRAM 2 19 Frame and engine right side view...

Страница 74: ...CABLE ROUTING DIAGRAM 2 21 Handlebar front view...

Страница 76: ...CABLE ROUTING DIAGRAM 2 23 Frame and engine top view...

Страница 78: ...CABLE ROUTING DIAGRAM 2 25 Frame and battery top view...

Страница 80: ...CABLE ROUTING DIAGRAM 2 27 Rear brake right side view...

Страница 82: ...CABLE ROUTING DIAGRAM 2 29 Front brake front view and right side view...

Страница 84: ...CABLE ROUTING DIAGRAM 2 31 Taillight top view and right side view...

Страница 86: ...CABLE ROUTING DIAGRAM 2 33...

Страница 131: ...GENERAL CHASSIS 4 5 a Projection b Slot c Rib side cover d Rib rear fender a a a 1 1 c c b b d d...

Страница 201: ...CHECKING THE SHIFT DRUM ASSEMBLY 5 73 CHECKING THE TRANSMISSION 5 73 INSTALLING THE TRANSMISSION 5 74...

Страница 204: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 5 3 1 Oil filter element 2 Oil pump...

Страница 205: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 5 4 1 Intake camshaft 2 Exhaust camshaft...

Страница 206: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 5 5 1 Camshaft 2 Oil pressure check bolt 3 Oil pump 4 Oil filter element...

Страница 259: ...SHIFT SHAFT 5 58 TIP Align the punch mark a on the shift shaft with the punch mark b in the shift pedal 1 1 2 2 a b...

Страница 265: ...OIL PUMP 5 64 A Primary drive gear side B Crankcase cover side 5 7 mm 0 02 0 28 in 5 c d 6 8 b 8 6 7 E...

Страница 278: ...TRANSMISSION 5 77...

Страница 288: ...WATER PUMP 6 9...

Страница 298: ...THROTTLE BODY 7 9...

Страница 301: ......

Страница 302: ...IGNITION SYSTEM 8 1 EAM20142 IGNITION SYSTEM EAM30277 CIRCUIT DIAGRAM...

Страница 306: ...ELECTRIC STARTING SYSTEM 8 5 EAM20143 ELECTRIC STARTING SYSTEM EAM30279 CIRCUIT DIAGRAM...

Страница 312: ...CHARGING SYSTEM 8 11 EAM20144 CHARGING SYSTEM EAM30282 CIRCUIT DIAGRAM...

Страница 315: ...CHARGING SYSTEM 8 14...

Страница 316: ...SIGNALING SYSTEM 8 15 EAM20154 SIGNALING SYSTEM EAM30348 CIRCUIT DIAGRAM...

Страница 320: ...LIGHTING SYSTEM 8 19 EAM20153 LIGHTING SYSTEM EAM30346 CIRCUIT DIAGRAM...

Страница 323: ...LIGHTING SYSTEM 8 22...

Страница 324: ...COOLING SYSTEM 8 23 EAM20155 COOLING SYSTEM EAM30350 CIRCUIT DIAGRAM...

Страница 327: ...COOLING SYSTEM 8 26...

Страница 328: ...FUEL INJECTION SYSTEM 8 27 EAM20145 FUEL INJECTION SYSTEM EAM30284 CIRCUIT DIAGRAM...

Страница 353: ...FUEL INJECTION SYSTEM 8 52...

Страница 354: ...FUEL PUMP SYSTEM 8 53 EAM20146 FUEL PUMP SYSTEM EAM30287 CIRCUIT DIAGRAM...

Страница 388: ...SELF DIAGNOSTIC FUNCTION AND DIAGNOSTIC CODE TABLE 9 15...

Страница 398: ...CHASSIS 10 9...

Страница 400: ......

Страница 402: ......