2-4

E

SPEC

MAINTENANCE SPECIFICATIONS

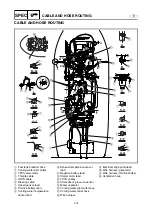

JET PUMP UNIT

Crankshaft assembly

Crank width

A

mm

(in)

72.95–73.00 (2.872–2.874)

Deflection limit

B

mm (in)

0.05 (0.002)

Deflection limit

C

mm (in)

0.15 (0.006)

Big end side clearance

D

mm

(in)

0.250–0.750 (0.0098–0.0295)

Maximum small end axial

play

E

mm (in)

2.000 (0.0787)

Throttle body

Model/quantity

60TA/3

Manufacturer

SANSHIN

ID mark

60T00

Trolling speed

r/min

1,250–1,450

Reed valves

Thickness

mm (in)

0.6 (0.024)

Reed valve stopper height

mm (in)

10.5–10.9 (0.413–0.429)

Reed valve warpage limit

mm (in)

1.5 (0.059)

Fuel pump

Pump type

Electrical

Output pressure

kPa

(kgf/cm

2

, psi)

320.8–327.2 (3.21–3.27, 45.62–46.53)

Coupling clearance

Vertical

mm (in)

0–0.5 (0–0.020)

Horizontal

mm (in)

2–4 (0.079–0.157)

Item

Unit

Model

GP1300R

Jet pump

Impeller material

Stainless steel

Number of impeller blades

4

Impeller pitch angle

Degree

16.3

Impeller clearance

mm (in)

0.7–0.9 (0.028–0.035)

Impeller clearance limit

mm (in)

0.9 (0.035)

Drive shaft runout limit

mm (in)

0.30 (0.0118)

Nozzle diameter

mm (in)

85.0–85.6 (3.35–3.37)

Item

Unit

Model

GP1300R

Содержание WaveRunner GP1300R

Страница 1: ...SUPPLEMENTARY SERVICE MANUAL GP1300R WaveRunner F1G 28197 1G 1X LIT 18616 02 90 LIT186160290...

Страница 10: ...E TROUBLE ANALYSIS TROUBLE ANALYSIS 48 SELF DIAGNOSIS 48 WIRING DIAGRAM...

Страница 61: ...YAMAHA MOTOR CORPORATION USA Printed in USA Dec 2004 0 0 1 CR E...

Страница 62: ...SERVICE MANUAL GP1300R WaveRunner F1G 28197 1F 11 LIT 18616 02 44 LIT186160244...

Страница 320: ...8 31 E HULL HOOD SEAT AND HANDGRIP SERVICE POINTS Seat lock inspection 1 Check Seat lock Damage wear Replace...

Страница 340: ...YAMAHA MOTOR CORPORATION USA Printed in USA Feb 2003 0 0 1 CR E...