EAS20090

HOW TO USE THIS MANUAL

This manual is intended as a handy, easy-to-read reference book for the mechanic. Comprehensive

explanations of all installation, removal, disassembly, assembly, repair and check procedures are

laid out with the individual steps in sequential order.

• The manual is divided into chapters and each chapter is divided into sections. The current section

title “1” is shown at the top of each page.

• Sub-section titles “2” appear in smaller print than the section title.

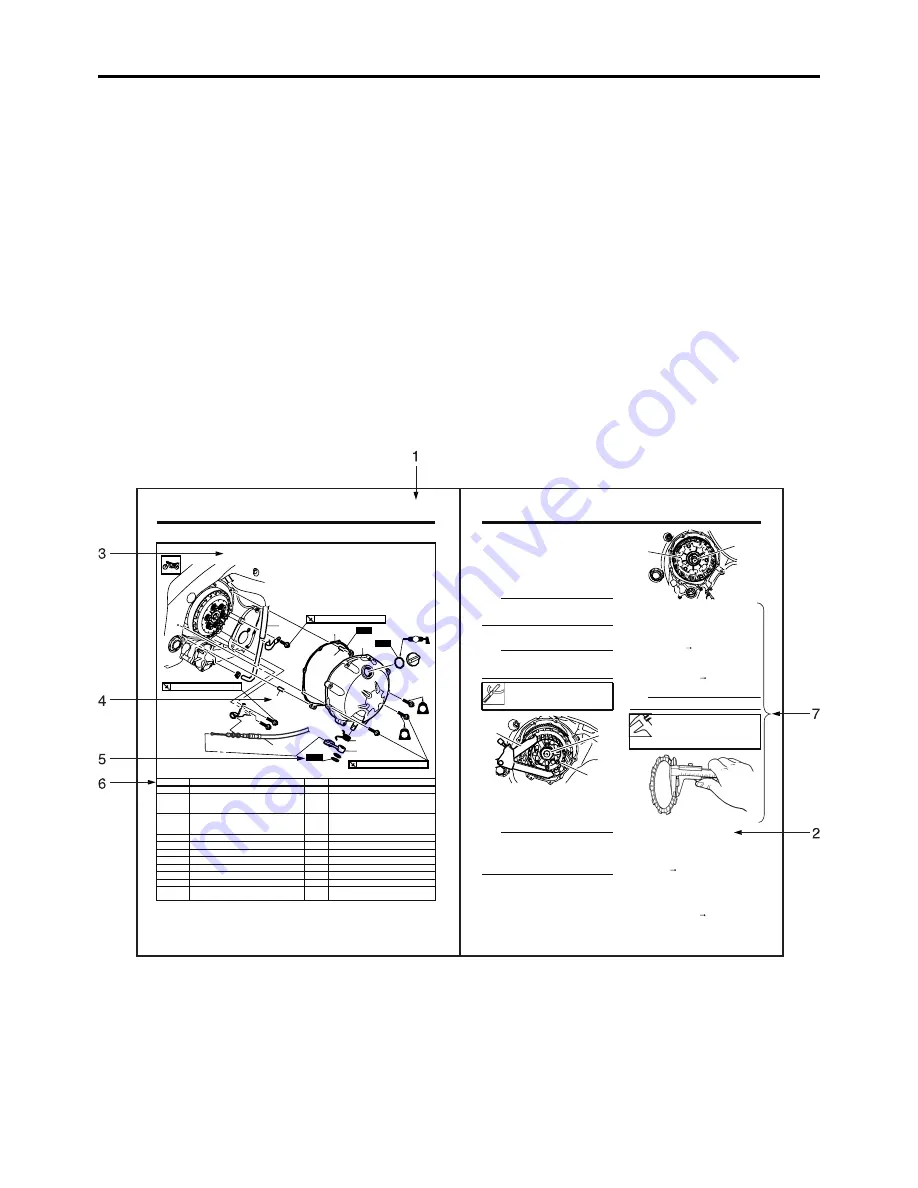

• To help identify parts and clarify procedure steps, there are exploded diagrams “3” at the start of

each removal and disassembly section.

• Numbers “4” are given in the order of the jobs in the exploded diagram. A number indicates a dis-

assembly step.

• Symbols “5” indicate parts to be lubricated or replaced.

Refer to “SYMBOLS”.

• A job instruction chart “6” accompanies the exploded diagram, providing the order of jobs, names

of parts, notes in jobs, etc.

• Jobs “7” requiring more information (such as special tools and technical data) are described

sequentially.

CLUTCH

5-36

EAS25060

CLUTCH

Removing the clutch cover

Order

Job/Parts to remove

Q’ty

Remarks

.

1

-

4

e

g

a

p

n

o

”

S

I

S

S

A

H

C

L

A

R

E

N

E

G

“

o

t

r

e

f

e

R

y

l

b

m

e

s

s

a

g

n

il

w

o

c

e

d

i

S

Engine oil

Drain.

Refer to “CHANGING THE ENGINE OIL” on

page 3-12.

Coolant

Drain.

Refer to “CHANGING THE COOLANT” on

page 3-21.

.

t

c

e

n

n

o

c

s

i

D

1

e

s

o

h

r

e

h

t

a

e

r

b

p

m

u

p

r

e

t

a

W

1

.

t

c

e

n

n

o

c

s

i

D

1

e

l

b

a

c

h

c

t

u

l

C

2

1

r

e

v

e

l

ll

u

P

3

1

g

n

i

r

p

s

r

e

v

e

l

ll

u

P

4

1

r

e

v

o

c

h

c

t

u

l

C

5

1

t

e

k

s

a

g

r

e

v

o

c

h

c

t

u

l

C

6

2

n

i

p

l

e

w

o

D

7

For installation, reverse the removal proce-

dure.

5

2

6

7

1

3

4

7

LT

New

New

LT

New

LS

T

R

.

.

12 Nm (1.2 m

•

kg, 8.9 ft

•

Ib)

T

R

.

.

12 Nm (1.2 m

•

kg, 8.9 ft

•

Ib)

T

R

.

.

12 Nm (1.2 m

•

kg, 8.9 ft

•

Ib)

CLUTCH

5-40

EAS25070

REMOVING THE CLUTCH

1. Remove:

• Oil strainer

Refer to “OIL PUMP” on page 5-48.

• Water pump

Refer to “WATER PUMP” on page 6-8.

• Friction plates

• Clutch plates

NOTE:

Be sure to mark the friction plates and clutch

plates or note the position of each part so that

they are installed in their original positions.

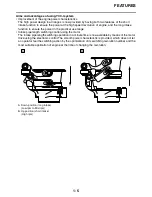

2. Loosen:

• Clutch boss nut “1”

NOTE:

While holding the clutch boss “2” with the uni-

versal clutch holder “3”, loosen the clutch boss

nut.

3. Remove:

• Spacer “1”

• Bearing

• Clutch housing “2”

• Oil pump drive chain

NOTE:

Remove the spacer and bearing from the main

axle, then remove the oil pump drive chain

from the oil pump driven sprocket, and then

remove the clutch housing and oil pump drive

chain from the main axle.

EAS25100

CHECKING THE FRICTION PLATES

The following procedure applies to all of the

friction plates.

1. Check:

• Friction plate

Damage/wear

Replace the friction

plates as a set.

2. Measure:

• Friction plate thickness

Out of specification

Replace the fric-

tion plates as a set.

NOTE:

Measure the friction plate at four places.

EAS25110

CHECKING THE CLUTCH PLATES

The following procedure applies to all of the

clutch plates.

1. Check:

• Clutch plate

Damage

Replace the clutch plates as

a set.

2. Measure:

• Clutch plate warpage

(with a surface plate and thickness gauge

“1”)

Out of specification

Replace the clutch

plates as a set.

Universal clutch holder

90890-04086

YM-91042

1

2

3

Friction plate thickness

2.92–3.08 mm (0.115–0.121 in)

Wear limit

2.80 mm (0.1102 in)

2

1