5

WARNING

WARNING

WARNING

WARNING

•When installing this product, be sure to connect a ground wire from the specified position of

this product (excluded NDP-5FPT, NDP-10, 15FP

□

, and DP-F series).

When this product is installed and operated without the ground wire properly connected, friction

between parts, as well as abrasion caused by the flow of some fluids inside the casing, may

generate static electricity. Also, depending on the type of fluid being pumped and the installation

environment (such as gases in the air and type of surrounding fixtures), static electricity could

become a cause of fire or electric shock.

•Improper grounding, poor ventilation, or unshielded fire or spark can create a danger of fire

or explosion. Therefore, the following precautions are strongly advised.

*All peripheral equipment and piping connected to this product should be properly grounded.

*To pump flammable liquids, use an ATEX compliant model.

*Whenever you notice any spark while operating this product, immediately stop its operation,

and do NOT start using it again unless you are sure of the cause and corrective actions have

been taken.

*Depending upon the type of fluid being pumped, bubbles of flammable gas may be generated.

Make sure that ventilation is satisfactory.

*This product itself, its piping and exhaust ports should be kept away from unshielded fire,

spark and other causes of ignition. If a diaphragm is damaged, fluid will gush out together

with air from the exhaust port.

*Do NOT leave gasoline or solvent etc. that contains waste at the work site.

*Machinery and other equipment near the place of installation of this product should be

properly insulated to prevent conduction with each other.

*Do NOT operate heating devices that create flames or have heating filaments anywhere near

the pump or the piping.

*If there are flammable gases in the air while the pump is operating, do NOT switch electric

appliances on and off.

*Do NOT operate a gasoline engine at the work site.

*Restrict smoking at the work site.

•The DP-F series pumps are intended for pumping hazardous fluids such as those that contain

strong acids or organic solvents. If you find any irregularity in this product, do

NOT try to disassemble or service the product yourself. Contact your dealer or our regional office

for service.

If you disassemble or service this product yourself and if further irregularity occurs, it may cause

a great risk, depending upon the kind of fluid to be pumped.

•After you shut down the pump and disconnect the piping, some fluid may remain inside the pump.

Also, if the pump is left unused for a prolonged period, some fluid may remain inside the pump

and connected piping. Therefore, be sure to purge the system of fluid and clean the pump before

prolonged disuse.

If the product is left unused for a prolonged period with fluid remaining in the connected piping as

well as the pump itself, the fluid may expand, depending on the ambient temperature (because of

freezing or heat), which may cause damage to the pump and/or piping and possible leakage of fluid.

•Always use genuine Yamada parts when replacing component parts of this product.

Do NOT attempt to modify the components parts or replace them with other than

genuine Yamada parts.

•Torque of all tightening parts must be inspected before operation.

Designated torques is mentioned in maintenance manual.

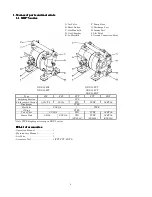

Содержание DP-10/12 series

Страница 42: ...42 NDP NDP NDP NDP 25BF 25BF 25BF 25BF NDP NDP NDP NDP 25BP 25BP 25BP 25BP NDP NDP NDP NDP 25BV 25BV 25BV 25BV ...

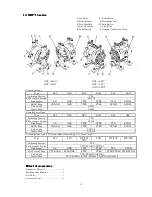

Страница 44: ...44 NDP NDP NDP NDP 40 40 40 40BP BP BP BP NDP NDP NDP NDP 40BV 40BV 40BV 40BV ...

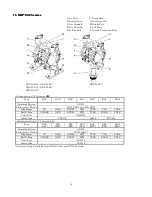

Страница 48: ...48 NDP NDP NDP NDP 80BF 80BF 80BF 80BF NDP NDP NDP NDP 80BP 80BP 80BP 80BP ...

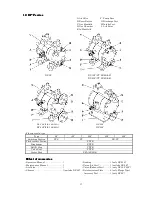

Страница 56: ...56 10 10 10 10 3 3 3 3 10 10 10 10 DP DP DP DP F F F F series series series series ...