10

Fig.16

air supply valve

rubber

At disassembly, even if one side seems to be broken, replace both left and right sides

simultaneously in respect of valve parts.

[NOTE] The anti-loosing wire cannot be reused. Do not use an alternative wire. Be sure to

replace the locking wire with a new one.

④

After removing the valve stem on the left and right sides, pull up the trip rod. Then,

peripheral parts including the reversing valve body can be disassembled as shown in the

illustration (Fig.14).

[NOTE]

If the trip rod is stretched too forcibly, its parts may be scattered by strong spring

force.

⑤

Check the air supply valve, discharge valve, and packing of the end of the valve shaft by

crushing and stretching. If even a small flaw is found, be sure to replace the

corresponding parts of both sides simultaneously.

⑥

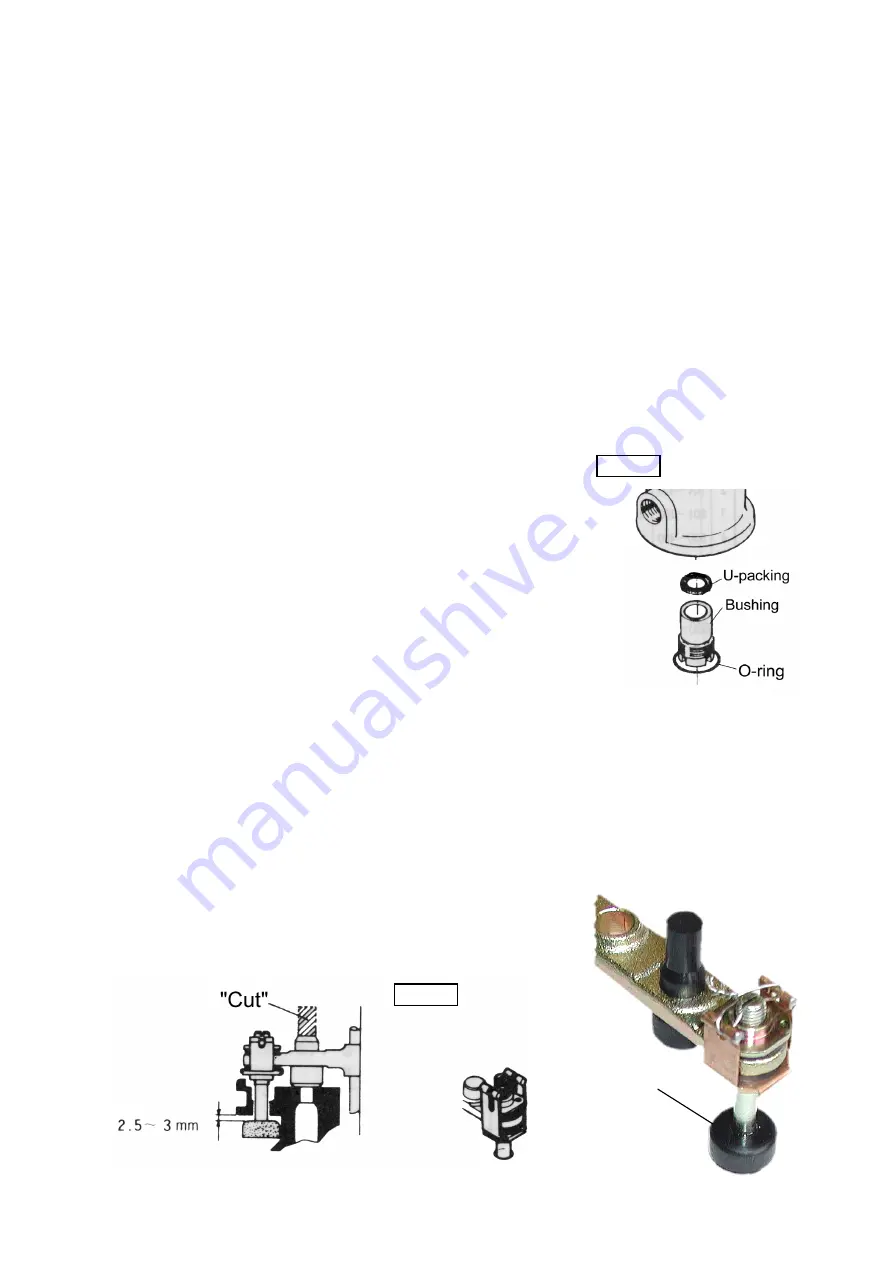

At re-assembly, pay attention to the up/down direction of reversing bar. (Fig.16)

(4) Disassembling the Packing gland

①

Unscrew the and remove it from the lower part of the body.

The bushing and U-packing can be disassembled. (Fig.15)

(For the bushing , prepare a metal flat bar with a width of

about 45 mm and a thickness of about 3 mm, and insert it in

the notch of the bushing. Then, unscrew it for removal.)

②

Check the U-packing for abrasion. If necessary, replace it.

(5) Precautions on assembling the Reversing valve

Make an adjustment carefully by interposing a coin as a gauge so that the clearance between

the reversing valve and the piston may be 2.5 mm to 3 mm. It is important to finish both

left and right clearances with the same dimensions. (Fig.16)

①

Turn the groove of the valve stem with a bladed screwdriver to make an adjustment.

②

The groove of the valve stem should be at a right angle to the reversing bar because the

anti-loosing wire must be passed through it lastly.

③

To replace the discharge valve, cut it off with a cutter and insert a new discharge valve as

shown in the figure. (Be sure to replace two discharge

valves simultaneously. If a new part and the old part are

combined for use, a difference in rubber hardness has a

bad effect, resulting in a failure.)

Fig.15

Содержание 850097

Страница 17: ...12 5 5 Parts Disassembly Drawing and Parts List Parts Disassembly Drawing ...

Страница 21: ...MEMO ...