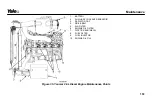

1.

FORK

2.

LOCK PIN

3.

SPRING

4.

WASHER

5.

WEDGE

6.

KNOB

7.

LOCK PIN ASSEMBLY

Figure 38. Fork Lock Pin Assembly

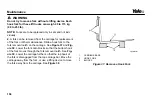

Forks, Inspect

1.

Inspect the forks for cracks and wear. Check that the

fork tips are aligned as shown in

. Check that the

bottom of the fork is not worn (Item 4 in

2.

Replace any damaged or broken parts that are used to

keep the forks locked in position.

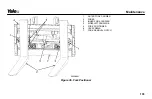

Forks, Install

1.

Move the fork and carriage so that the top hook on the

fork can engage the upper carriage bar. Raise the carriage

to move the lower hook through the fork removal notch.

Slide the fork on the carriage so that both upper and lower

hooks engage the carriage. Engage the lock pin with a

notch in the upper carriage bar. See

.

2.

If lift truck is equipped with a fork positioner, install inner

fork carriers using four capscrews. Tighten capscrews to

35 N•m (25 lbf ft). See

Maintenance

157

Содержание VERACITOR GCC030VX

Страница 20: ...SEE THE PARTS MANUAL FOR THE PART NUMBER Figure 4 Warning and Safety Labels Sheet 2 of 3 Model Description 18...

Страница 21: ...SEE THE PARTS MANUAL FOR THE PART NUMBER Figure 4 Warning and Safety Labels Sheet 3 of 3 Model Description 19...

Страница 24: ...Figure 6 Display Switch Cluster Right Side Display Inputs Model Description 22...

Страница 40: ...Figure 8 Operator Controls Sheet 2 of 2 Model Description 38...

Страница 83: ...Figure 13 Seat Adjustment Full Suspension Operating Procedures 81...

Страница 115: ...1 DRIVE TIRES 2 STEERING TIRES Figure 17 Put a Lift Truck on Blocks Maintenance Schedule Maintenance Schedule 113...

Страница 124: ...Figure 26 Yanmar 2 6L Diesel Engine Prior to January 2011 Maintenance and Lubrication Points Maintenance Schedule 122...

Страница 172: ...Figure 43 LPG Tank and Bracket Maintenance 170...