Clean

WARNING

Cleaning solvents can be flammable and toxic and

can cause skin irritation. When using cleaning

solvents, always follow the solvent manufac-

turer’s recommended safety precautions.

WARNING

Compressed air is used for cleaning and drying

purposes, or for cleaning restrictions. Wear pro-

tective clothing (goggles/shields, gloves, etc.).

Make sure the path of the compressed air is away

from all personnel to avoid injury.

1.

Clean metal parts in solvent. Remove all traces of

old lubricant and dirt. Clean nonmetal parts with

warm soapy water and a lint free cloth.

2.

After cleaning, dry parts with compressed air. DO

NOT dry parts with a cloth.

Inspect

1.

Inspect for loose, burned, missing, cracked or

damaged hardware.

2.

Inspect all parts for dents, holes, bends, burrs,

rust, corrosion or marred finishes.

3.

Replace all defective or damaged parts.

Assemble

NOTE:

This procedure is for installation of all compo-

nents of steering column assembly. Not all compo-

nents are removed for a repair procedure. Do only

those steps of procedure necessary to install required

component.

NOTE:

PerformStep 1 only for lift trucks manufac-

tured before January, 2012.

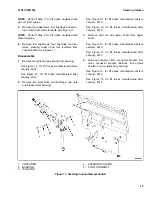

1.

Lubricate horn contact slip rings with a small

amount of conductive grease (Yale P/N

582014302).

2.

Install fastener, connector bracket and connector,

two horn contacts and four screws.

See Figure 12, for lift trucks manufactured before

January 2012.

See Figure 13, for lift trucks manufactured after

January 2012.

3.

Assemble lower shaft and upper shaft, secure

with spit pin.

See Figure 12, for lift trucks manufactured before

January 2012.

See Figure 13, for lift trucks manufactured after

January 2012.

4.

Install two pivot bolts, two bushings, two nuts and

bracket onto housing.

See Figure 12, for lift trucks manufactured before

January 2012.

See Figure 13, for lift trucks manufactured after

January 2012.

5.

Install gas spring and two pins on housing.

See Figure 12, for lift trucks manufactured before

January 2012.

See Figure 13, for lift trucks manufactured after

January 2012.

Install

NOTE:

Lubricate spline end of lower shaft with multi

purpose grease, see

Periodic Maintenance Manual

for your lift truck.

NOTE:

Perform Step 1 for lift trucks equipped with

gas or LPG engines.

1.

Install steering column, four bushings and four

bolts on cowl standoffs. Tighten bolts to

38 N•m (28 lbf ft). See Figure 11.

NOTE:

Perform Step 2 for lift trucks equipped with

diesel engines.

2.

Install four isolators, steering column, four isola-

tors, four bushings, and four bolts on cowl stand-

offs. Tighten bolts to 38 N•m (28 lbf ft). See Fig-

ure 11.

3.

Install floor plate, floor mats, and steering column

covers. See section Hood, Seat, and Side Covers

Replacement.

4.

Install steering wheel and hex nut on steering col-

umn, tighten hex nut to 40 to 54 N•m (30 to

40 lbf ft). Connect electrical wiring and install horn

button. See Figure 10.

Steering Column

0100 YRM 1243

16

Содержание GDP100VX

Страница 13: ...Figure 7 Gas Spring Installation 0100 YRM 1243 Hood Seat and Side Covers Replacement 9 ...

Страница 36: ...Figure 25 GM 4 3L LPG Engine and Transmission with Single Hydraulic Tank Engine Replacement 0100 YRM 1243 32 ...

Страница 38: ...Figure 26 GM 4 3L LPG Engine and Transmission with Dual Hydraulic Tanks Engine Replacement 0100 YRM 1243 34 ...

Страница 40: ...Figure 27 Cummins QSB 3 3L Diesel Engine and Transmission Engine Replacement 0100 YRM 1243 36 ...

Страница 52: ...Figure 33 Cummins 4 5L Diesel Engine and Transmission Engine Replacement 0100 YRM 1243 48 ...

Страница 57: ...Thank you very much for your reading Please Click Here Then Get More Information ...