7000 Series Parts Manual

69

Copyright © 1998-2020, ASSA ABLOY Access and Egress Hardware Group, Inc. All rights reserved.

Reproduction in whole or in part without the express written permission of ASSA ABLOY Access and

Egress Hardware Group, Inc. is prohibited. Patent pending and/or patent www.assaabloydss.com/patents.

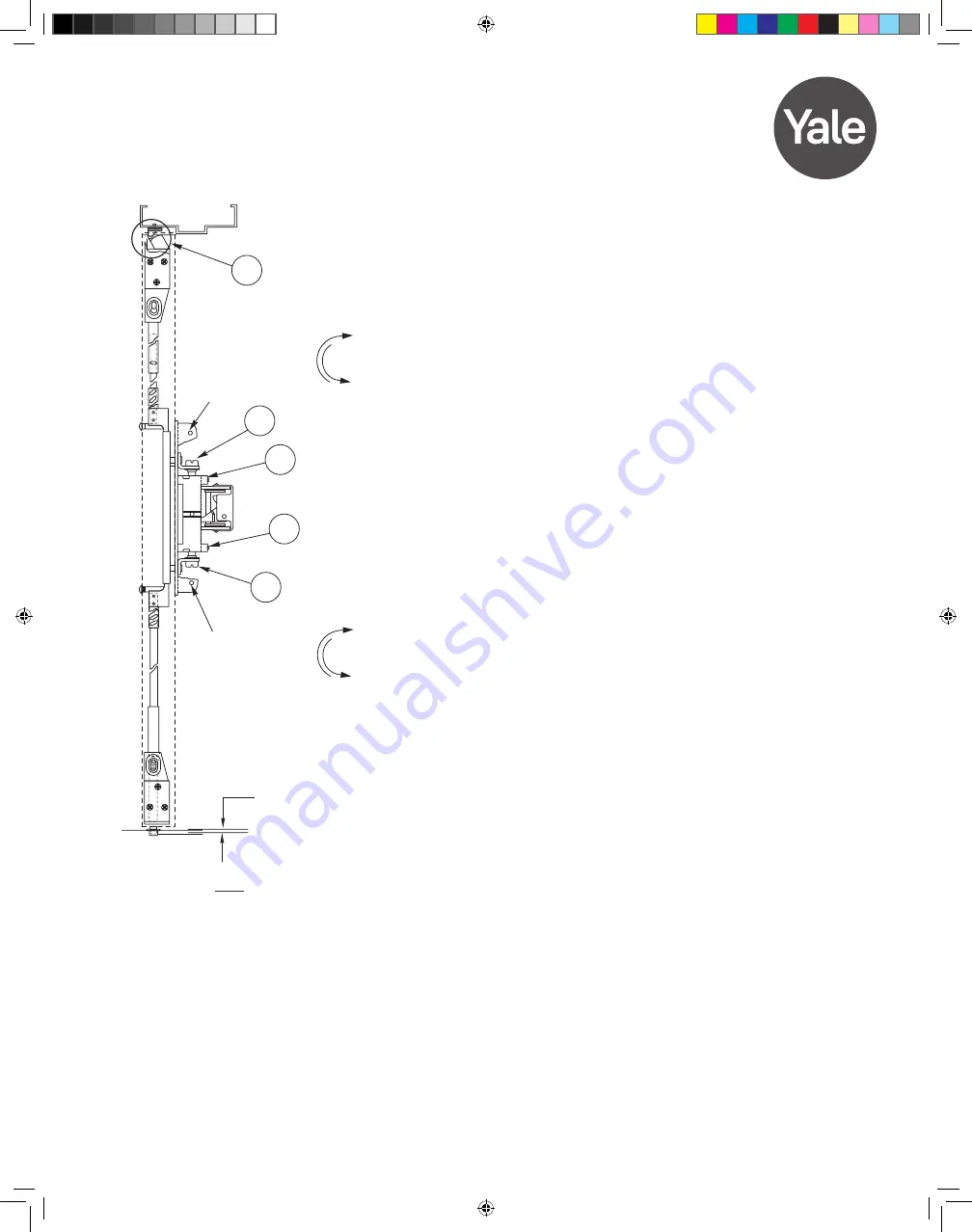

Concealed Vertical Rod Exit Devices

Rods should move freely inside door . Bolts extend automatically

when door closes and top strike is tripped . Top bolt should retract flat .

Bottom bolt should travel 1/2" and engage 3/8" into strike in down

position, without dragging on floor surface in up position .

If top latch does not engage properly check alignment . When locked,

latch bolt should not be preloaded by strike (

Area A

) . Shim or

reposition strike if necessary .

Rod Adjustment for Bolt Throw

1 . Remove Latch assembly cover screws and cover .

2 . Use 3/32" Allen wrench to loosen set screws

C

1

and

C

2

.

3 . Adjusting screws

B

1

and

B

2

only provide fine rod adjustment . If

screws bottom out before proper device operation, door and device

must be removed . Larger adjustments may then be made either by

threading rod in or out, or by moving cotter pin to different hole in

rod .

4 .

Adjust top rod first.

With device in dogged position (panic devices)

or touchbar fully depressed (fire devices), adjust top rod so that

the top latchbolt is flush and the hold back feature is engaged .

Lengthen top rod an additional 1/2 turn .

5 .

Adjust bottom rod.

With top latch retracted in hold back position,

and touch bar dogged or fully depressed, adjust bottom rod so that

the deadbolt clears the strike by 1/16" . The bottom rod should be

in position in the active case with the square head of the connector

hanging in the slide .

6 .

Check device operation

by opening and closing the door . When

present, operate the device with the outside trim . An additional

minor adjustment may be required for full retraction and correct

strike engagement .

7 . When finished, lock adjusting screws in place with Allen set

screws .

Caution:

To avoid thread damage and provide positive locking, be

sure Allen set screws engage flats on adjusting screws .

Maintenance

1 . Periodically remove covers and coat exposed mechanisms with

an appropriate lubricant . This is regularly required in corrosive

environments for proper product operation .

2 . Check mounting fasteners periodically . Retighten if found loose .

Apply screw locking compound or change part fasteners if screws

continue to back out .

3 . Periodic checks and adjustments of rods may be required to

compensate for door or frame sag .

LONGER

BOTTOM ROD

SHORTER

BOTTOM ROD

ADJUSTING SCREW

TOP ROD

ADJUSTING SCREW

LONGER

TOP ROD

SHORTER

COVER

SCREW

HOLE

COVER

SCREW

HOLE

3/8"

(10mm)

ENGAGEMENT

BOLT

B2

C2

C1

B1

A

7120

42210_Yale_7000_PM.indd 69

42210_Yale_7000_PM.indd 69

10/6/20 3:05 PM

10/6/20 3:05 PM