Installation

Determine location for the probe installation

DANGER:

Electrical hazard sufficient to kill. Always disconnect and lock out the power before you

service the unit.

NOTICE:

• Low water cut-off must be installed in series with all other limit and operating controls

on the boiler. Check for proper operation of all of the limit and operating controls

before leaving the site.

• All work must be performed by qualified personnel trained in the proper application,

installation, and maintenance of plumbing, steam and electrical equipment or systems

in accordance with all applicable codes and regulations.

Use the following criteria to locate a suitable position to install the probe .

• Install probe in a tapping on the boiler that is designated by the boiler manufacturer.

Review boiler IOMs or contact manufacturer for location of tapping.

• Probe must be installed below the location or level of the existing automatic reset low

water cut-off (LWCO). Installing the probe above this location could result in nuisance

shutdowns or lockouts.

• Install probe in a location above the minimum safe water level as designated by the

boiler manufacturer.

• Installing the probe in a location other than a tapping designated by the boiler

manufacturer could result in nuisance shutdowns of the burner.

• There must be at least 1/4 in of clearance between the end of the probe and the wall of

any piping or fitting.

• Do not install the probe in any pipe extension that covers all or part of the probe rod.

Water that is retained in a pipe extension and touches the probe prevents the probe

from recognizing a low water condition. The burner will not shut off.

Install the probe

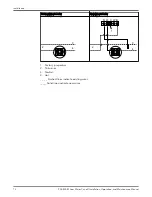

1. Apply a small amount of pipe sealant to the external threads (2) of the probe (1).

IMPORTANT: Do not use PTFE tape. Only use a pipe sealant.

1

2

2. Tighten the probe (1) into the tapped connection (3) to 47 ft·lb (64 N·m).

Be sure to align the probe so that the mounting screws (4) are in a horizontal position.

Installation

PSE-800-M Low Water Cut-off Installation, Operation, and Maintenance Manual

7

Содержание McDonnell & Miller PSE-800-M

Страница 1: ...PSE 800 M Low Water Cut off Installation Operation and Maintenance Manual...

Страница 2: ......

Страница 18: ......

Страница 19: ......