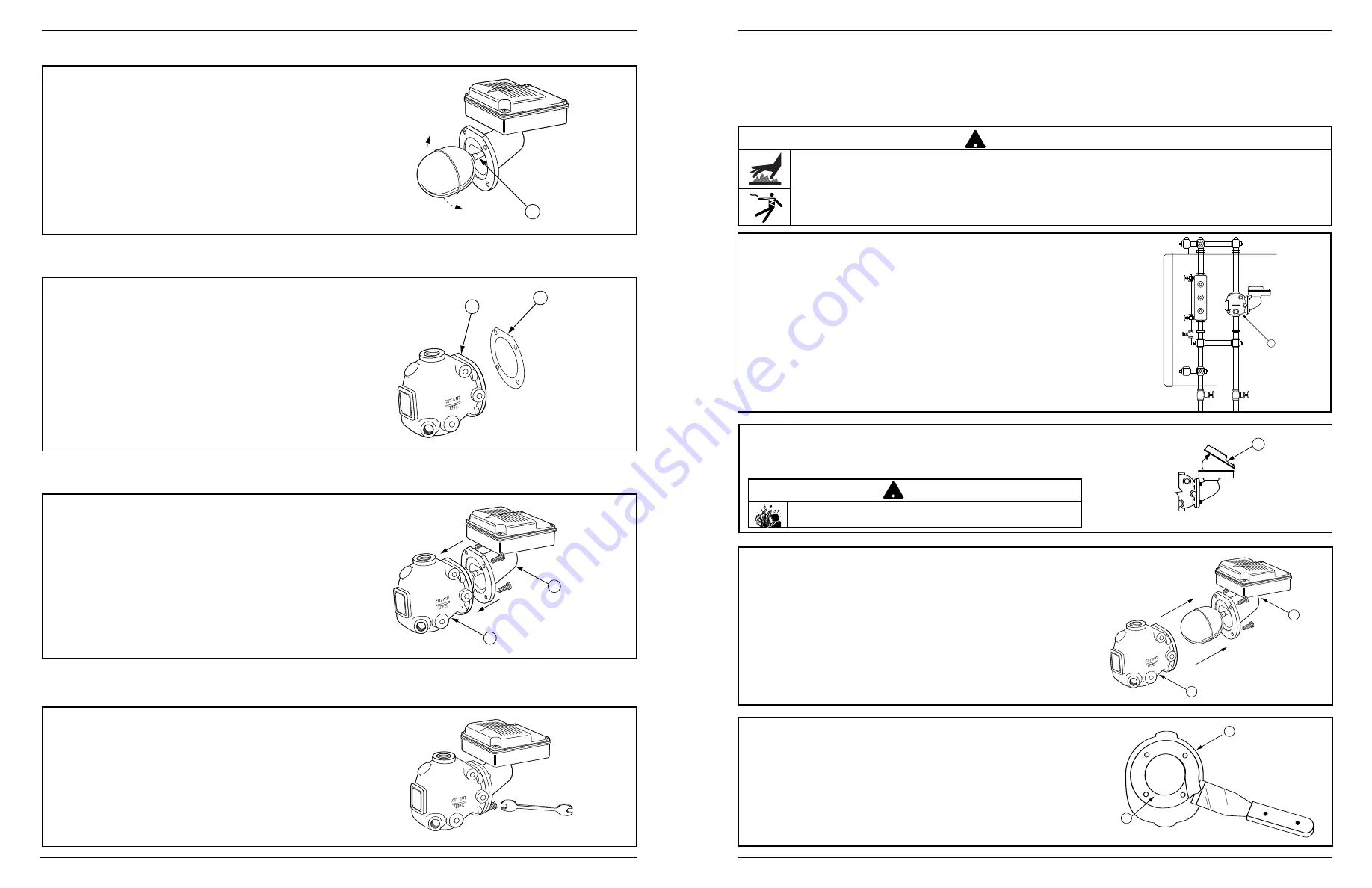

d.

Using a wrench, insert the four (4) bolts and

tighten them to approximately 14-20 ft•lb

(19-27 N•m) in an alternating star pattern.

G

F

H

b.

Align the bolt holes of the new head gasket

(H) on the sealing surface (F) of the control

body.

a.

Carefully remove the new replacement head

mechanism from the carton. Handle it carefully

to prevent damage to the float rod (G).

J

D

c.

Install the new replacement head (J) on the

body (D) by guiding the float into the control

body and aligning the bolt holes.

STEP 2 - Installing the Replacement Head Mechanism

4

3

A

B

C

D

c.

Remove the existing head mechanism (C)

from the body (D).

a.

Drain water in the boiler to a level which is

below the float chamber (A). Allow the boiler

to cool to 80˚F (27˚C) and release the boiler

pressure to 0 psi (0 bar).

b.

Using a flathead screwdriver, remove the junction

box cover (B). Disconnect, mark, and remove the

supply wires and conduit connections.

F

E

d.

Using a scraper, remove the old gasket (E).

Clean all debris from the float chamber. The

gasket sealing surface (F) must be smooth

and clean.

STEP 1 - Preparation

INSTALLATION –

TOOLS NEEDED:

One (1) pipe wrench, one (1) flathead screwdriver, one (1) scraper, and one (1) 9/16" socket or wrench.

• To prevent serious burns, the boiler must be cooled to 80˚F (27˚C) and the pressure must be 0 psi (0 bar)

before servicing.

• To prevent electrical shock, turn off the electrical power before disconnecting or making electrical connections.

Failure to follow this warning could cause property damage, personal injury or death.

!

WARNING

There may be more than one source of power to the boiler.

!

CAUTION